Joint Pricing and Inventory Decisions for Perishable Products

advertisement

Joint Pricing and Inventory Decisions for Perishable

Products

Onur Kaya (okaya@ku.edu.tr)

College of Engineering, Koc University

Aylin Lelizar Polat

College of Engineering, Koc University

Abstract

We consider perishable products and focus on the optimal pricing and inventory

decisions for these products in a deterministic setting. In this system, the demand rate is

affected with not only the prices of the products but also with the freshness and age of the

products. In addition, the products decay at a certain rate while they are in stock. We

analyze both a single product and a multi product model and considering the interactions

between the products, we aim to determine when to change the prices of the products, the

optimal values of these prices and when to replenish the inventory with new products.

We analyze the effect of different parameters on the optimal solution through numerical

experiments and obtain managerial insights.

Keywords: Pricing, Inventory, Perishable Products, Revenue Management

Introduction

In this study, we consider the inventory management and pricing of perishable products

such as milk, yogurt, eggs, bread, fresh fruits and vegetables, considering a price and

time dependent demand function. Effective management of perishable products is an

important issue for many companies and management of these products is especially

difficult for the managers because of the perishability risks of these products in a very

short time. Different than durable products, as the perishable products age, the demand

for these products start to decline and in a short time these products can become

completely obsolete. Thus, not only the amount of these products but also their status or

age effect the inventory and pricing decisions of these products making the problem

much harder to solve.

There are many studies in literature considering the inventory and pricing

decisions for perishable products, however most of these studies consider the inventory

and pricing decisions separate from each other and coordinated inventory and pricing

decisions are not studied as much. In addition, in most of the studies in literature, single

product systems are considered and demand is assumed to be time-independent. However,

in reality, due to customer choices, the actual demand depends on the age or status of the

products at hand in addition to their price. When the products are new or fresh, the

demand rate is high, however as the products age, they will be demanded less and the

customers can move to other types of products. Because of the change in demand over

time, it might be better to charge different prices at different times and employing a

1

dynamic pricing strategy might improve the profits substantially. In the literature most of

the inventory models assume that inventories can be held in stock indefinitely to satisfy

future demands. On the other hand most of the commodities either deteriorate or become

outdated, hence they are unstable. Most commonly used goods are exposed to

deterioration; like fruit, vegetable, meat, etc. Therefore if the rate of deterioration is not

sufficiently low, its impact on modeling of the inventory cannot be ignored.

In recent years, we have observed an increased adoption of dynamic pricing for

perishable products in manufacturing and retail industries. For instance, in food industry

decaying products like bread and vegetables have very short shelf life. They are generally

priced at the retail price when they come fresh. However they are sold at discounted

values when they come to their expiry date. So retailers can attract customers who are

more price sensitive with the aim of generating more revenue through their sales. It is a

complex task to determine a right price for the product which requires a wealth of

information about the status of the products at hand and customer preferences for

products with different freshness and price values. In the past, companies faced high

costs in changing prices and had insufficient information about customer demand. As a

result, companies always fixed the product's prices over a long period resulting in static

prices. However, today, with the improvements in technology, companies have much

more data about the customers and can change their prices at relatively low costs

suggesting a dynamic pricing policy to be more profitable.

In literature, deterministic joint inventory and dynamic pricing problem is generally

analyzed considering a single product. Raafat (1991) presents a survey for the inventory

management of deteriorating items and Goyal and Giri (2001) present a review of

advances of deteriorating inventory literature since the early 1990s. Abad (1996) assumes

that prices can be changed continuously at no cost and determines the optimal price p(t)

as a continuous function of time. Transchel and Minner (2009) consider discrete pricing

of non-perishable products assuming a fixed cost for changing prices. Mukhopadhyay et

al. (2004) consider perishable products, but they assume a single price to be charged over

the whole cycle and do not consider price changes. In addition, they assume that the

demand function is independent of time. Sana (2010) considers an EOQ model for

perishable items where demand is price dependent and partial backorder is allowed. They

determine the optimal prices and the order size but they assume that the timings of the

price changes are fixed. Rajan and Rakesh (1992) consider the relationship between

pricing and ordering decisions for perishable products by allowing a continuous price

change over the cycle. Broekmeulen and Donselaar et al. (2009) analyze a perishable

product system considering the age of products and they propose a replenishment policy

and compare their results with the optimal policy that does not take into account the age

of inventories.

In this study we consider a deterministic model and focus on the coordinated

pricing and inventory decisions. Different from the studies stated above, we consider both

single and multiple product systems with perishable products that decay at a certain rate

and the demand is both time and price dependent. We assume that the prices can be

changed at any time at a certain cost and we aim to find the best times to change the

prices as well as the optimal values of these prices. Every time an order is given for fresh

products, a fixed order cost is incurred in addition to the inventory holding costs for the

products kept at hand. The objective of the model is to maximize the profit per unit time

2

by choosing the optimal lot size and the pricing strategy where the retailer can change

price over time. We analyze this system for both single and multi product cases

considering the demand interactions between the products. We provide explicit results for

the optimal solution in the single product model and present an efficient heuristic to

determine the best solution for the multi product model. We observe that dynamic pricing

provides substantial benefits compared to the static pricing, allowing the companies to

substantially increase their profits.

Single Product Model

In this section, we consider a single perishable product and focus on the pricing and

inventory decisions for this product. We denote the time between two successive orders

for new products as an inventory cycle and during an inventory cycle, the price of the

product is changed several times in order to obtain the maximum possible profit. We let h

denote the inventory cost per unit per unit time, N denote the number of different prices

used in an inventory cycle and f denote the cost of changing the price such that Nf

denotes the total cost of changing prices in an inventory cycle. In our model, ti, i=1,2..N-1,

denotes the time of the ith price change with t0=0 and tN denotes the end of an inventory

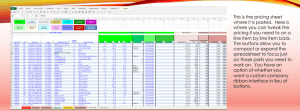

cycle at which time new and fresh products are ordered. Figure 1 presents an illustration

of an inventory cycle.

Figure 1- Illustration of the Inventory Process

We let pi denote the price during the time interval [ti-1, ti). In this model, due to

perishability of the product, the inventory is depleted partly to meet the demand and

partly for deterioration. We assume that each product at hand decays at a constant rate θ

independent of the other products such that the decay rate of all inventory is given by

w(t)=θI(t) at any time t, as a function of the instantaneous inventory level at that time,

denoted as I(t). Note that Q= I(0) denotes the batch size ordered at the beginning of each

cycle. Every time an inventory replenishment order is given, a fixed order cost A and per

unit cost c is incurred such that the total cost at the time of order will be A+cQ. We

3

describe the inventory function I(t) by the differential equation (1) which consists of the

decay rate and the price and time dependent demand rate, D(p,t), such that:

𝐼 ′ (𝑡) = -D(p,t)- θI(t)

(1)

For any t in the interval [ti-1, ti], the inventory equation below satisfies equation (1)

and the boundary condition Ii(ti) = I(ti).

𝐼𝑖 (𝑡) = 𝑒

−𝜃𝑡

𝑡𝑖

∫ 𝐷(𝑝, 𝑠) 𝑒 𝜃𝑠 𝑑𝑠 + 𝐼(𝑡𝑖 )𝑒 𝜃(𝑡𝑖 −𝑡)

𝑡

For the purpose of obtaining explicit results, we consider a linear demand function

that is decreasing in price and time, such that D(p,t)=a-bp-kt. However, we note that the

same analysis as in this paper can be done and similar results can be obtained for

different types of demand functions. Solving the above differential equation for the linear

demand function results in the following inventory function at any time t where ti-1 ≤ t ≤ ti

for all i=1,2,…N.

𝐼𝑖 (𝑡) = (

𝑎−𝑏𝑝𝑖

𝜃

−

𝑘𝑡𝑖

𝜃

𝑘

+ 𝜃2 + 𝐼(𝑡𝑖 ))𝑒 𝜃(𝑡𝑖 −𝑡) −

𝑎−𝑏𝑝𝑖

𝜃

+

𝑘𝑡

𝜃

𝑘

− 𝜃2

(2)

We let Si denote the sales amount during time period [ti-1, ti) such that

𝑡𝑖

𝑆𝑖 = ∫ (𝑎 − 𝑏𝑝𝑖 − 𝑘𝑠)𝑑𝑠

𝑡𝑖−1

Then the profit per unit time can be written as:

1

𝑘𝑝𝑖

𝑁

2

2

𝜋 = 𝑡 {−𝐴 − 𝑐𝑄 − 𝑁𝑓 + ∑𝑁

𝑖=1(𝑎𝑝𝑖 − 𝑏𝑝𝑖 )(𝑡𝑖 − 𝑡𝑖−1 ) −

𝑘𝑡𝑖

𝜃2

𝑘

− 𝜃3 −

𝐼(𝑡𝑖 )

𝜃

𝑎−𝑏𝑝𝑖

) (1 − 𝑒 𝜃(𝑡𝑖 −𝑡𝑖−1 ) ) − (

𝜃

𝑘

2

(𝑡𝑖2 − 𝑡𝑖−1

) − ℎ[(−

𝑘

2

)]}

+ 𝜃2 ) (𝑡𝑖 − 𝑡𝑖−1 ) + 2𝜃 (𝑡𝑖2 − 𝑡𝑖−1

𝑎−𝑏𝑝𝑖

𝜃2

+

(3)

In this study, we need to determine the optimal values of N, pi and ti values for all

i=1,2,…N. We observe that for a given N, we can find the optimal pi and ti values using

the first order derivatives of the equation (3). Thus, we solve this problem using a twostage approach as follows, where 𝜋(𝑁) denotes the profit function for a given N.

Stage 1: 𝑀𝑎𝑥𝑁 𝜋(𝑁) − 𝐾(𝑁)

s.t. N ≥ 1

Stage 2: 𝑀𝑎𝑥𝑝,𝑡 𝜋(𝑁)

s.t. ti ≥ ti-1 ≥ 0

pi ≥ 0

D(pi,ti) ≥ 0

for all i=1,2,..N

for all i=1,2,..N

for all i=1,2,..N

We observe that for a given N, the second stage problem is jointly concave w.r.t p

and t and thus, we first solve the second stage problem for a given N and determine the

optimal price and time values as a function of N. Then, we solve the first stage problem

4

to determine the optimal value of N using the results of the second stage problem. For a

given N, the optimal price values can be found through equation (4) as functions of ti

values. Then, we solve the second stage problem by combining equation (4) with the first

order derivatives of the profit function (3) with respect to ti.

𝑎

𝑘

ℎ

𝑝𝑖 = 2𝑏 − 4𝑏 (𝑡𝑖 + 𝑡𝑖−1 ) − 2𝜃 +

𝑎−𝑏𝑝𝑖

ℎ [(

𝜃

𝑎−𝑏𝑝𝑖+1

𝜃

𝑘

ℎ(𝑒 𝜃(𝑡𝑖 −𝑡𝑖−1 ) −1)

2𝜃2 (𝑡𝑖 −𝑡𝑖−1 )

𝑎−𝑏𝑝𝑖+1

)

+ 𝜃2 + 𝐼(𝑡𝑖 )) (𝑒 𝜃(𝑡𝑖 −𝑡𝑖−1 ) + (−

𝜃

2

] = −𝑏𝑝𝑖2 − (𝑝𝑖 − 𝑝𝑖+1 )(𝑎 + 𝑘𝑡𝑖 ) + 𝑏𝑝𝑖+1

𝑓𝑜𝑟 ∀𝑖=1,2..N

+

𝑘𝑡𝑖+1

𝜃

(4)

𝑘

− 𝜃2 − 𝐼(𝑡𝑖+1 )) (𝑒 𝜃(𝑡𝑖+1 −𝑡𝑖 ) ) +

𝑓𝑜𝑟 ∀𝑖=1,2..N-1

(5)

Using a one-dimensional search over N, we find the optimal time and price values

for each N and then by comparing the profits in each case, we obtain the best N and the

corresponding optimal pi and ti values. Note that when N=1, this system corresponds to a

static pricing model in which the price is not allowed to change during a cycle. In the

numerical results section, we compare the results of this static pricing model with the

dynamic pricing case in which the prices are allowed to change during the cycle at a

certain cost.

Substitutable and Perishable Two Product Model

In this section, we consider two different products which are substitutable in nature such

that the demand for each product depends not only on that product’s price and freshness

but also it depends on the other product’s values. We employ a similar analysis here, as in

the previous section. We assume that both products are replenished at the same time such

that the length of the inventory cycle is the same for both products. Even though, this can

be seen as a restrictive assumption, this is a common procedure in reality since similar

products are obtained from the same supplier and they are ordered simultaneously.

Ordering these products separately also causes a high fixed order cost. However, during

the inventory cycle, their prices can be changed at different times.

We let ti1 and ti2 i=1,2..N-1, denote the time of the ith price change for products 1

and 2, respectively with t01= t02=0 and tN1= tN2 denote the end of an inventory cycle. Note

that at each time of a price change, only one of the products’ price is changed, however,

we don’t know which. This makes the analysis complicated since during an interval [ti-1,1,

ti1), the demand function of the first product might change if the price of the second

product changes at some time in this interval. Thus, we need to consider where each ti2

lies with respect to each ti1 value and because of this reason, we cannot write the profit

function of each product independently from the other in terms of these prices and times.

To overcome this difficulty, we concatenate the time arrays ti1 and ti2 to obtain a single

array ti which contains all times of the price changes in a strict ordering. We let pi1 and pi2

denote the price during the time interval [ti-1, ti). However, note that, in this case, at any ti

we do not know which price is changed, thus one of the pi values need to stay constant in

successive intervals while the other can change. Using the demand functions D1(p1, p2,

t)=a1-b1p1+e1p2-k1t and D2(p1, p2, t)=a2-b2p2+e2p1-k2t, we use the same analysis as in the

single product model and obtain the inventory and profit functions similar to the ones in

the previous section as below.

5

𝐼𝑖𝑗 (𝑡) = (

𝑎𝑗 − 𝑏𝑗 𝑝𝑖𝑗 + 𝑒𝑗 𝑝𝑖𝑘 𝑘𝑗 𝑡𝑖 𝑘𝑗

𝑎𝑗 − 𝑏𝑗 𝑝𝑖𝑗 + 𝑒𝑗 𝑝𝑖𝑘 𝑘𝑗 𝑡 𝑘𝑗

−

+ 2 + 𝐼𝑗 (𝑡𝑖 ))𝑒 (𝑡𝑖 −𝑡) −

+

−

𝜃𝑗

𝜃𝑗

𝜃𝑗

𝜃𝑗 𝜃𝑗2

𝜃𝑗

1

𝑘𝑗 𝑝𝑖𝑗

𝑁

2

2

𝜋𝑗 = 𝑡 {−𝐴𝑗 − 𝑐𝑗 𝑄𝑗 − 𝑁𝑗 𝑓𝑗 + ∑𝑁

𝑖=1(𝑎𝑗 𝑝𝑖𝑗 − 𝑏𝑗 𝑝𝑖𝑗 + 𝑒𝑗 𝑝𝑖𝑗 𝑝𝑖𝑘 )(𝑡𝑖 − 𝑡𝑖−1 ) −

2

) − ℎ𝑗 [(−

𝑡𝑖−1

2

𝑎𝑗 𝑝𝑖𝑗 −𝑏𝑗 𝑝𝑖𝑗

+𝑒𝑗 𝑝𝑖𝑗 𝑝𝑖𝑘

2

𝑎𝑗 𝑝𝑖𝑗 −𝑏𝑗 𝑝𝑖𝑗

+𝑒𝑗 𝑝𝑖𝑗 𝑝𝑖𝑘

(

𝜃𝑗

𝜃𝑗2

𝑘

+

𝑘𝑗 𝑡𝑖

𝜃𝑗2

𝑘

− 𝜃3𝑗 −

𝑗

𝐼𝑗 (𝑡𝑖 )

𝜃𝑗

(𝑡𝑖2 −

) (1 − 𝑒 𝜃𝑗 (𝑡𝑖 −𝑡𝑖−1 ) ) −

𝑘

2

)]}

+ 𝜃2𝑗 ) (𝑡𝑖 − 𝑡𝑖−1 ) + 2𝜃𝑗 (𝑡𝑖2 − 𝑡𝑖−1

𝑗

𝑗

where j={1,2} and k is the complement of j (i.e. k=2 when j=1 and vice-a-versa). Then

the problem can be written as

Max 𝜋 = 𝜋1 + 𝜋2

s.t. ti ≥ ti-1 ≥ 0

pij ≥ 0

Dj(pij, pik, ti) ≥ 0

pij = pi+1,j

for all i=1,2,..N

for all i=1,2,..N, j=1,2.

for all i=1,2,..N

if price of the other product is changed at time ti for j=1,2.

In this case, at any time ti since only one of the prices of the products is changed,

one of the pi values need to stay constant in successive intervals and this makes the

problem very complicated and we cannot obtain explicit results for the optimal pi and ti

values. However, we observe that if we know the ti1 and ti2 values, then we know which

price is changed at each ti and optimal prices in each time interval can be found explicitly

through the first order derivative of the profit function. Using this observation, we design

a heuristic algorithm to find the optimal solution.

To obtain the optimal results for this system, we employ a genetic algorithm. In this

algorithm, starting with a set of arrays of ti1 and ti2 values, we calculate the best pi1 and pi2

values using the derivative of the profit function and calculate the optimal objective

function value for the given time array. Then using mutation and crossover operators, we

obtain new time arrays for the timings of the price changes. The mutation operator in our

algorithm works as follows: At each iteration, we randomly select one of the values in

our time arrays and either increase or decrease it by a random amount leading to a new

solution. Then for this new time array we calculate the corresponding optimal price

values in each time interval using the derivatives of the profit function and then calculate

the objective function value. If the new solution leads to better solution than the previous

one, we continue doing the same operation until no further improvement is obtained. We

also use a crossover operator in our algorithm which works as follows: We take two time

arrays and we randomly pick one of the elements in one of these arrays. For example, let

[a1, a2, … ai, ai+1, … aN] and [b1, b2, … bj, bj+1, … bM] denote these two arrays and ai

denote the element that is chosen. Then we determine the closest time in the other time

array that is larger than the element that we picked, let it be bj+1. Then we exchange the

initial portions of these two arrays and obtain two new solutions as [b1, b2, … bj, ai+1, …

aN] and [a1, a2, … ai, bj+1, … bM]. Using these operators, we update our results and

continue in the same manner until no further improvements can be obtained in the

algorithm for a certain number of iterations or an upper bound is reached in the number

6

of iterations.

Computational Results

In this section, we numerically analyze the benefits of dynamic pricing for the single

product model and observe the impacts of the system parameters on the results. As a base

case, for the single product model, we use the parameters a=100, b=1, k=1, c=10, h=0.01,

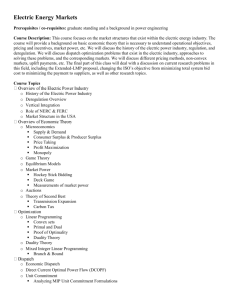

θ=0.01, f=100 and A=1000. In Table 1, we present the results for the dynamic pricing

model as well as the results for the static pricing case, as a benchmark, in which the price

is not allowed to change during a cycle. In the first row of Table 1, we present the results

for this base case and in the following rows of this table, we do a sensitivity analysis by

changing one of these parameters as stated in the first column of Table 1.

Table 1 - Single Product Model Results

Dynamic Pricing Model

Parameter Profit Order Cycle

Waste

Size

Length

Ratio

Base Case 1061

1112

42.8

0.09

a=200

4954

5721

91.2

0.24

a=50

209

182

10.8

0.03

b=2

392

832

37.9

0.08

b=0.5

2322

1293

46.8

0.11

k=2

1064

558

23.2

0.04

k=0.5

1008

2341

81.4

0.18

c=20

819

818

38.2

0.07

c=5

1154

1293

46.9

0.10

h=0.02

1059

1101

42.7

0.08

h=0.005

1065

1115

43.1

0.09

1023

1173

40.9

0.17

θ=0.02

0.05

θ=0.005 1072 1058 43.6

1039

1104

42.5

0.10

f=200

1084

1128

43.2

0.09

f=50

0.09

A=2000 1041 1135 43.1

1079

1087

42.6

0.08

A=500

Profit

949.6

4300

197.4

343.5

2189

948.4

915.6

716

1081.8

946

951

907

968.9

949.6

949.6

926

961

Static Pricing Model

Order Price Cycle

Size

Length

1106

56.4 43.6

5648

109.6 90.4

185

27.7 10.3

829

30.9 38.1

1282

106.6 46.7

549

54.9 22.5

2266

58.9 82.2

807

62.3 37.6

1290

53.2 46.8

1098

56.5 43.5

1111

56.3 43.7

1160

58.5 41.5

1069

55.5 44.5

1106

56.4 43.6

1106

56.4 43.6

1133

55.9 44.1

1093

56.6 43.4

Waste

Ratio

0.14

0.28

0.05

0.12

0.15

0.07

0.25

0.12

0.15

0.14

0.14

0.26

0.07

0.14

0.14

0.14

0.14

We observe that dynamic pricing results in a 12% increase in profits on average as

opposed to the single price model. In addition, the number of decayed products decrease

with dynamic pricing. However, the order size and the cycle length with dynamic pricing

can be higher or lower than the values with static pricing. When we look at the effects of

the parameters on the system, we observe that as the market size, a, increases, the order

size, cycle length and the profits increase substantially but a much higher wastage rate is

observed since more units are ordered in a cycle. In addition, the benefit of dynamic

pricing increases with a, since there is a larger room for improvement in a system with a

larger market size. When we consider the price sensitivity of demand, b, we observe that,

as b increases, less profit is obtained due to decrease in demand. The order size and the

cycle length also decrease and less amount of products are wasted as b increases. In

addition, as b increases, since the system will be more sensitive to pricing, the benefit of

dynamic pricing compared to the static pricing model increases. When b=0.5, the profit

7

with dynamic pricing is about 6% better than the profit with static pricing while this

value increases to 14% when b=2. When the time sensitivity of demand, k, increases, the

order size and the cycle length decrease and less amount of products is decayed. Next,

we consider the cost of the products, c, and observe that as c increases order size, cycle

length and profits decrease and less units are wasted. In addition, the benefit of dynamic

pricing also increases with c. The reason for this is that as the products become more

valuable, dynamic pricing and effective management of the products become more

important. We observe that as the inventory holding cost increases, profits decrease and

less units are ordered in each cycle leading to shorter cycle lengths. Similarly, when the

wastage rate increases, profit and the cycle length decrease, but we observe that more

units are ordered in each cycle in order to cover the high amount of decay and have

enough good products at hand for sale. Even though, the order size increases, since the

products decay at a faster rate, the cycle length decreases with θ. Next, we consider the

cost of changing the prices and observe that as f decreases, dynamic pricing will be more

useful and the prices are changed more often. As a results, profit increases and the

wastage rate decreases. Lastly, we consider the fixed order cost, A, and observe that as A

increases, more units are ordered and the cycle length increases as the wastage rate, while

the profits decrease.

When we look at the prices in the dynamic pricing model, we observe that, at the

beginning of the cycle a higher price than the static price is charged but the price is

decreased as time increases and becomes lower than the static price through the end of

the cycle. The reason for this is that, at the beginning, there is a higher demand for the

fresh products and charging a higher price is optimal. However, as time increases the

demand decreases as the products’ freshness decrease and lower prices are charged to

maximize the profits with this lower demand function.

Conclusion

In this study, we analyze the coordinated pricing and inventory decisions for perishable

products in a deterministic setting in which the demand not only depends on the price but

also on the freshness of the products. In addition, the products in inventory are assumed

to decay at a certain rate which adds another dimension to the problem. We derive

explicit results for the optimal order size, optimal number of times the prices should be

changed and the optimal price values at each time for the single product case and we

propose a heuristic to approximate the optimal solution in the multi product model.

Through numerical experiments, we compare the results with the dynamic pricing policy

with the single pricing case in which the price is not allowed to change throughout the

selling period. We observe that substantial benefits can be obtained by changing the

prices throughout the selling period.

Our model can be extended in several ways. Firstly, different types of demand

functions or decay processes can be analyzed in detail and explicit results can be obtained.

In addition, this problem can be analyzed in the stochastic setting in which the demand

and also the decaying process is random. Even though our results can form a basis for

developing coordinated pricing and inventory policies that can be also applied in

stochastic environments, the performances of such policies need to be investigated and

effective policies need to be developed for stochastic systems.

8

Acknowledgements

We are grateful to Tubitak for its support to our work through Tubitak 1001 Grant

#111M533.

References

Abad P. L., (1996), Optimal pricing and lot-sizing under conditions of perishability and partial

backordering, Management Science, 42, 1093–1104,.

Broekmeulen RACM, van Donselaar K.H., (2009), A heuristic to manage perishable inventory with batch

ordering, positive lead-times, and time-varying demand. Computers and Operations Research, 36, 3013–

3018.

Goyal S.K., Giri B.C., (2001), Recent trends in modeling of deteriorating inventory, European Journal of

Operational Research, 134(1), 1–16.

Mukhopadhyaya, S., Mukherjee, R.N., Chaudhuri, K.S., (2004), Joint pricing and ordering policy for a

deteriorating inventory, Computers and Industrial Engineering , 47, 339-349.

Raafat F., (1991), Survey of literature on continuously deteriorating inventory models. Journal of

Operations Research Society, 42(1), 27–37.

Rajan, A., Rakesh, R., (1992), Dynamic pricing and ordering decisions by a monopolist, Management

Science, 38, 240–262.

Sana, S.S., (2010), Optimal selling price and lot size with time varying deterioration and partial

backlogging, Applied Mathematics and Computations, 217(1), 185-194.

Transchel, S., Minner, S., (2009), The impact of dynamic pricing on the economic order decision. European

Journal of Operational Research, 773-789.

9