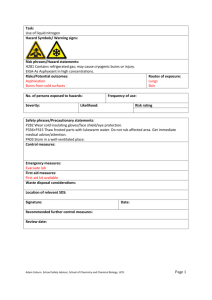

Risk Assessment - Newcastle University

Title of project or activity

Responsible Person /

Manager

School

Date of assessment

Location of work

(Buildings and room numbers)

Introduction

Newcastle University

Risk Assessment

[ENTER DETAILS HERE]

[ENTER DETAILS HERE]

[ENTER DETAILS HERE] dd/mm/yyyy

[ENTER DETAILS HERE]

The following risk assessment and guidance has been developed to assess the hazardous activities, risks and identify appropriate prevention and control measures. A simple implementation check is provided to assist schools in demonstrating that the control measures are being implemented. Please identify when they have been implemented.

Activities with Hazardous Potential and Significant Risks

These are contained within the shaded area. The first shaded area in the assessment identifies the hazard or hazardous activity and the second identifies the risks imposed by that activity.

Preventative and Protective Measures to Avoid or Reduce Risks to an

Acceptable Level

These are contained within the un-shaded areas. This section identifies the control measures required and may require schools to choose options or carry out additional risk assessments.

Help and Support

Safety Office

Occupational Health

Service

Schools must visit the University Safety Office website. The website contains a wide range of guidance to assist schools to manage health and safety effectively including University

Safety Policies and Supplements, Safety Guidance,

Training, Forms, etc.

Hazard 1

Risks

Control

Measures

Exposure to wood dust/ metal fluids or other substances

Implemented Date

Risk of lung diseases from inhaling wood dust.

Hardwood dust can cause cancer.

Chemical fluids can cause harm if in contact with skin or eyes

Specific COSHH assessment completed for each harmful substance.

Hazard 2

Manual handling*

See manual handling additional page at the end of this risk assessment

Implemented Date

Risk Assessment v3 Page 1 of 6

Risks

Control

Measures

Staff or students may suffer musculoskeletal disorders such as back pain from handling heavy, bulky objects e.g. timber boards or machinery parts.

Also risk cuts when handling tooling, or splinters when handling pallets.

Staff trained in manual handling techniques.

Work benches and machine tables set at comfortable height.

Strong, thick gloves provided and worn for handling tools and pallets.

Consider use of panel trolley and/ or lifting hooks available for moving boards.

Use team lift for large, awkward or heavy loads.

Minimise delivery distances. Site material stores close to roadways and workshops.

Hazard 3

Risks

Noise

Implemented Date

Staff and students may suffer temporary or permanent hearing damage from exposure to noise from woodworking machinery.

Noise enclosures used where reasonably practicable, and maintained in

Control

Measures good condition.

Low noise tooling used where possible.

Planned maintenance programme for machinery and LEV systems.

Suitable hearing protectors or disposable ear plugs (for students) provided. Staff and student trained in how to use them. Check and maintain hearing protectors according to supplier.

Staff trained in risks of noise exposure.

Staff trained in system of work to reduce noise exposure e.g. feed rates for certain jobs.

Contact Occupational Health and Safety Service (OHSS) for advice and further monitoring if concerned about noise levels in workshop.

Risks

Implemented Date

Hazard 4 Deliveries

Staff may suffer serious, possibly fatal injuries if struck by a vehicle such as a delivery lorry.

Roadways controlled by Estates Support Service. Discuss improvements

Control

Measures to difficult or congested delivery areas to segregate vehicles from pedestrians as far as possible.

Minimise need for delivery vehicles to reverse as much as possible.

Arrange deliveries to coincide with quiet times on campus as far as possible.

No lift trucks to be used associated with delivery vehicle.

Items not to be lifted over walkways or pedestrians using Hi-Ab arm.

Hazard 5

Risks

Slips, trips and falls

Implemented Date

Staff or students could suffer injuries such as bruising or fractures if they trip over objects, or slip e.g. on spillages or wood dust/ metal fluid.

Generally good housekeeping – off cuts/ waste cleared away promptly,

Control

Measures dust or fluids collected and spillages cleaned immediately.

Students encouraged to clean work area after they have finished.

Regular inspections by technicians.

Risk Assessment v3 Page 2 of 6

Staff wear strong safety shoes that have a good grip.

Good lighting in all areas.

Implemented Date

Hazard 6 Electrical

Staff or students could get electrical shocks or burns from using faulty

Risks electrical equipment e.g. machinery or a faulty installation. Electrical

Control

Measures faults can also lead to fires.

Residual current device (RCD) built into main switchboard.

Main electrical system tested by Estates Support Service.

Portable appliance testing (PAT) testing carried out in accordance with

Health and Safety Executive guidance .

Any portable appliances belonging to students must be PAT tested before use on University premises.

Hazard 7 Work at Height

Risks

Implemented

Falls from any height can cause bruising and fractures

Control

Measures

Date

Limited work at height in workshops.

Window cleaning carried out by outside contractors.

Changing light bulbs done by ESS.

Strong stepladder, in good condition provided. Follow Health and Safety

Executive guidance on ladder safety .

Hazard 8 Fire

Risks

Implemented Date

If trapped staff and students could suffer fatal injuries from smoke inhalation/ burns.

Control

Measures

Fire risk assessment completed by University Fire Officer.

Risks

Implemented Date

Hazard 9 Use of Hand Tools

Staff or student at risk of serious or minor injuries caused by using hand tools.

All tools should be inspected regularly by technicians and students prior to use. All defective tools must be taken out of use until repairs or discarded and replaced.

Any hand tools with blades should be sheathed when stored. Tools must be stored in such a manner that they do not present a risk when selecting

Control

Measures or picking up.

All staff are experienced and may be formally trained in safe use of hand tools by a competent person.

Students are provided with safety inductions and monitored by staff to ensure they follow best practice in the use of hand tools. If deemed necessary by supervising technician students will be required to redo safety induction.

Ensure any personal protective equipment identified in the COSHH or general risk assessment is available and worn.

Risk Assessment v3 Page 3 of 6

Students may bring their own hand tools into the workshop. Technicians will monitor the adequacy of any ‘students own’ hand tools and have the right to request that any defective tools are removed immediately. A full range of University supplied hand tools is available in the workshop and students will be encouraged not to use their own tools in the workshop.

Hazard

10

Use of:

Jigsaws

Reciprocating saw

Circular saw

Band saw

Cross cut saw

Hand router

Spindle Moulder

Implemented Date

Pedestal Drill/ Cordless Drills

Planer/ Thicknesser

Risks

Control

Measures

Staff or students at risk serious and possibly fatal cut injuries following contact with moving parts or machinery.

Inhalation of fumes and dust- see separate COSHH assessment

All machines guarded and used according to manufacturer’s instructions or local work procedures. Local procedures are attached to each machine.

All machines are braked and fitted with necessary safety features e.g. chip limited tooling.

Guards inspected regularly and maintained as necessary to ensure their good condition.

Staff and students have sufficient space at machines to work safely.

Maximum occupancy levels are set for each workshop which are enforced by technicians.

Staff are aware that some tasks can be completed using more than one machine. Staff will consider and choose the most suitable i.e. safest machine to complete work tasks and advise students on machine selection.

Technicians are present at all times when the workshop is open.

All staff are trained in safe use of machines by a competent person. Any additional training needs are identified through individual personal development reviews (PDR’S)

Students are not allowed to use certain machinery. Machinery is clearly marked ‘ not for student use ’ and may be isolated.

Students are provided with safety inductions and monitored by staff to ensure they follow best practice and in particular use guards correctly. If deemed necessary by supervising technician students will be required to

Risk Assessment v3 Page 4 of 6

redo safety induction.

Maintenance only carried out by trained staff with machine isolated.

Students are instructed to report any defect or problems to technicians.

Ensure any personal protective equipment identified in the COSHH is available and worn. Gloves and eye protection will be needed for any machine where there is a risk of ejection of material.

Add additional hazards here e.g.

Hazard

11 Use of laser cutter/ 3D printer/ forge/ welding equipment etc

Risks

Control

Measures

Name Signature

[ENTER HERE] [ENTER HERE]

Responsible Person / Manager

Implemente d

Date

Date

[ENTER HERE]

Name

[ENTER HERE]

Signature

[ENTER HERE]

Please see manual handling analysis form on the next page.

Date

[ENTER HERE]

N/A

Risk Assessment v3 Page 5 of 6

Manual Handling Analysis Form

This checklist for detailed analysis of manual handling activities is not in itself a full manual handling risk assessment. A full risk assessment should be completed on the manual handling risk assessment form and this form appended to it.

Name………………………………………….. Position………………………………………….

Date…………………………………………… School…………………………………………..

Description

When

Raising or

Lowering

When

Carrying

When

Pushing or Pulling

When

Seated

THE TASK - Do the tasks require:

1 Holding the load at a distance from the body?

2 An awkward posture?

3 Awkward twisting?

4 Awkward stooping?

5 Reaching upwards?

6 Handling the load over excessive distances?

7 Stabilising an unstable load?

8 Prolonged physical effort?

9 Repetitive handling?

10 Insufficient rest period?

11 Any unsatisfactory combination of several tasks?

THE LOAD - Are the loads:

1 Heavy?

2 Bulky or unwieldy?

3 Difficult to grasp?

4 Unstable?

5 Potentially damaging (e.g. sharp edge)?

THE ENVIRONMENT - Is there:

1 Lack of space?

2 Uneven/slippery/unstable floors

3 Extremes of temperature, humidity or air movement?

4 Variation of levels of floor and work surface?

5 Poor lighting?

INDIVIDUAL CAPABILITY - Do the tasks:

1 Require above average physical capabilities irrespective of sex?

2 Involve risk to pregnant workers or those with health problems?

3 Require Manual Handling instruction?

Risk Assessment v3 Page 6 of 6