Implementation Plan

advertisement

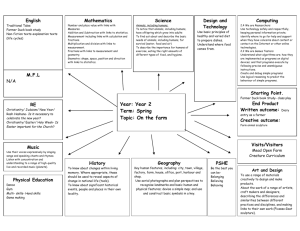

Implementation Plan To address the water shortage issue of Tecolote farm, we have selected to use all three of the solutions researched by Robin Robèrt. All three of the technologies – subsurface drip irrigation, water harvesting, and a deeper well – will be integrated together and with the existing infrastructure on the farm in order to maximize effectiveness and minimize cost. The first technology we will install is a subsurface drip irrigation system to ensure that as little water is wasted on the farm as possible. We will also drill a third, deeper well to make sure the farm has an adequate ground water supply. However, we have selected to drill only to a depth of 100 feet. The risk and cost involved in drilling 2500+ feet into the lower Trinity Aquifer are too great (Cottingham, 2008); the water may be contaminated, and the sheer cost of the well would be staggering, most likely exceeding the $1,000,000 grant amount. The new and old wells, however, will not be the farm's main water supply. As Tecolote Farm’s water crisis has shown, wells drawing from the Trinity Aquifer cannot be relied upon as secure sources of water. Instead, we will construct a rainwater harvesting system (RWHS) to serve as the farm’s main source of irrigation water. We conclude that a supplemental catchment array will supply the farm with the water it will need for an average annual growing season. The roof of the owner’s home and barn are insufficient in area to provide for all of the farm’s irrigation needs. We will design and construct a catchment surface approximately 130x400 feet. This new surface area, coupled with the roof and barn, and assuming an average annual rainfall of 33.7 inches will provide the farm up to 900,000 gallons of water throughout one year (National Weather Service Forcast Office, 2008). According to Mr. Pitre the farm currently uses a maximum of 880,000 gallons of water each year to irrigate ten acres of crops, so the farm will be able to collect just enough water with the RWHS under average rainfall conditions. Should a drought ensue, the farm will have the new well to provide it with a backup source of water. Schedule Figure 3 shows the schedule for the implementation of all three projects, beginning on February 2nd, 2009 and ending by May 1st, 2009. Should the proposal be accepted, we will quickly implement each of the three solutions to allow the farm to continue its work as normal. The installation of the rainwater catchment array and the third well should not interrupt farming, but it will be necessary to install the drip irrigation immediately to allow the farm to begin operations before the spring growing season. First, we will begin soliciting bids from local contractors for the installation of the drip irrigation system, replacement of the roofs and gutters on the house and barn, and drilling of the third well. Because we have chosen a subsurface drip irrigation system, the field will need to be excavated for the installation process, and therefore no growing can occur while the drip irrigation system is being installed. Installation of the irrigation system will be accomplished before March 1st so that the farm's spring growing season, which begins in early March, may begin unhindered. To that end, while cost and quality of the irrigation system will be primary concerns in selecting a contractor for this task, the ability to meet 4/26/2009 4/19/2009 4/12/2009 4/5/2009 3/29/2009 3/22/2009 3/15/2009 16 4 6 5 2 5 3 7 2 10 10 7 7 8 58 14 5 41 4 3/8/2009 Tue 2/17/09 Thu 2/5/09 Mon 2/9/09 Tue 2/10/09 Fri 2/6/09 Sat 2/7/09 Wed 2/11/09 Tue 2/17/09 Tue 3/3/09 Wed 2/11/09 Wed 2/11/09 Tue 2/24/09 Tue 3/3/09 Wed 2/25/09 Tue 5/1/09 Sun 3/1/09 Fri 2/20/09 Tue 5/1/09 Fri 3/20/09 3/1/2009 Mon 2/2/09 Mon2/2/09 Wed 2/4/09 Fri 2/6/09 Thu 2/5/09 Tue 2/3/09 Mon 2/9/09 Wed 2/11/09 Mon 2/2/09 Mon 2/2/09 Mon 2/2/09 Wed 2/18/09 Thu 2/26/09 Wed 2/18/09 Mon 2/16/09 Mon 2/16/09 Mon 2/16/09 Thu 3/5/09 Tue 3/17/09 2/22/2009 Finalize RWHS Design 1 Verify Water Need 2 Verify Water Collection Potential 3 Select Materials 4 Finalize Surface Architecture 5 Verify Storage Need 6 Select Rain Barrel 7 Design Water Transport System Solicit Contractor Bids 8 Drip 9 Roofing 10 Catchment Array and Water Storage 11 Well 12 Consult Hydrologists (well location) Construction 13 Drip Irrigation 14 Roofs and Gutters 15 RWHS 16 Well 2/15/2009 FINISH 2/8/2009 START 2/1/2009 TASKS DURATION (days) the March 1st completion date will be the primary factor in our selection of a contractor. Figure 1 – Project Implementation Schedule from 2/2/2009 to 414/2009 Although the roofs and gutters are part of the rainwater harvesting system, their replacement can be accomplished independently of the design and construction of the catchment array. We will solicit local roofing companies for bids to replace the shingle roofing and guttering on the house with aluminum equivalents. While we are collecting bids, we will work with outside engineers to finalize a design of the catchment array. Our collaboration with other engineers will be primarily to analyze data, and to verify that the designed system, including catchment surfaces and storage barrels, has enough capacity to meet the water needs of the farm. The designing process of the RWHS will include the design of transport systems from the catchment surfaces to the rain barrel and from the rain barrel to the field. Once the plan has been finalized, we will contact local contractors to bid on the construction. We plan to have the construction of the rain water catchment system completed by May 1st, and we will select a contractor according to this schedule. Since the farm still has one well providing it with water, the drilling of the third well is a lower priority. We will first consult with hydrologists to determine the most ideal location for the well. Once the site has been established, we will select a contractor to drill the well. Because of the well’s low priority, selection of a contractor will be based primarily on cost. Once the construction bids have been received, we will select contractors and begin construction. Contractors will be in charge of all materials purchasing and labor hiring; however, our consulting firm will remain on hand to supervise the construction process. Upon completion of the drip irrigation system and RWHS, we will ask Tecolote Farm to begin keeping detailed records of their water collection and consumption. We will ask for daily water levels in the rain barrels and water usage on the field from May 1, 2009 to May 1, 2010. We will use this data to measure the effectiveness of our solution by comparing it with the farm’s own data from previous years, and then make recommendations for changes that may be necessary at the end of the first year. The preliminary schedule is based on estimates only, and the actual times for tasks, especially those involving contractors, may vary significantly. Start dates are proposed only, but there is one hard completion deadline: the installation of the drip irrigation system by March 1st. We will have all construction and installation completed by May 1st. Budget Our Budget is based on current industry-standard pricing, and estimated consultation time and construction costs. More detailed line-item budgets will be retrieved from contractors as bids are collected. For consulting fees, we have given our best estimates of the amount of time needed to complete the tasks. Table 1 – Budget Low Cost Estimate High Cost Estimate Subsurface Drip Irrigation System with Rain-Shutoff Device Rain Sensor Subsurface Drip Irrigation Materials and Installation Cost Subtotal $27.00 $104,544.00 $104,571.00 $69.99 $121,968.00 $122,037.99 Rainwater Harvesting System Aluminum Roof and Gutters for House and Barn 120,000-Gallon Corrugated Galvanized Steel Water Cistern 1,000 feet of PVC pipe (10" dia.) 231'x231' Corrugated Aluminum 6,522 Lumber Boards (2'x4'x10') Subtotal $27,000.00 $101,192.17 $17,926.50 $133,402.50 $21,294.00 $300,815.17 $32,000.00 $113,783.73 $21,000.00 $186,763.50 $21,294.00 $374,841.23 Well Total Cost of Drilling 100-ft Well $17,500.00 $25,000.00 All Project Labor 10 Workers @ $10-$20/hour and 75 hours per Worker $7,500.00 $15,000.00 Robin Robèrt Consulting Fees Research and Project Development -- 72 Hours @ $35/hour Outside Consulting -- 50 Hours @ $35/hour Subtotal $2,520.00 $1,750.00 $4,270.00 $2,520.00 $1,750.00 $4,270.00 Total Cost $434,656.17 $541,149.22 Estimated values derived from information from the following sources: (Schwab, 2008), (Renovation Experts, 2008), (American Tank Company, 2008), (U.S. Plastic Corporation, 2008). Table 1 shows that the largest proportion of the budget will pay for the rain water harvesting system, which is estimated to cost between $300,000 and $400,000 to install. Included in this cost is the removal and replacement of the shingling and gutters on the house and barn with aluminum equivalents. Also included in the cost are the 120,000-gallon steel water cistern, and the materials to build the 130x400-ft water catchment array. Although corrugated aluminum is an expensive material, it is necessary to use this inert metal to ensure that the water that contacts it does not become contaminated. The second largest proportion of the budget will pay for the installation of the subsurface drip irrigation system, which will cost between $100,000 and $150,000. The estimates for the irrigation system were calculated from an EPA cost calculator spreadsheet, which accounted for the size of the irrigated area, average local rainfall rates, length of growing season, and frequency of irrigation. Also included in the cost is an inexpensive rain shut off device, which helps to conserve more water by shutting off the irrigation system when a sensor detects a minimum amount of rainfall (Schwab, 2008). Relatively inexpensive is the cost of drilling the 100-ft well, which ranges from $17,500 to $25,000. These low and high costs were estimated by extrapolation from the known price Tecolote farm paid to dig a 40-ft well on the farm in 2006. The 40-ft well cost $7,000, which when linearly extrapolated to 100 feet amounts to $17,500 (Cottingham, 2008). The high cost estimate of $25,000 accounts for possible exponential increases in drilling costs with increasing depth. Depending on wages and the number of workers, the provision of labor will cost from $7,500 to $15,000. The estimated costs are based on a total of 10 workers installing the irrigation system, RWHS, and the well for $10 to $20 per hour. The total time each worker is estimated to work during the entire implementation is 75 hours, for a combined total of 750 hours for all 10 workers. The smallest proportion of the budget will pay for consultant fees, and future project development. The low and high cost estimates are both $4,270 and are not expected to change considerably. Consultation costs account for 50 total hours of outside consultation with hydrologists, RWHS designers, and contractors. Research and project development once and if the grant is awarded will take up 72 hours, and the rate of $35 per hour set by Robin Robèrt yields a total cost of $2,520. The high estimate of the total cost is $541,149.22, which is slightly more than half of the grant offering. To provide a buffer against any cost under-estimations or price fluctuations, we will ask for that amount to implement the entire project. Conclusions and Further Recommendations The final plan includes a combination of all three technologies: a subsurface drip irrigation system, rainwater harvesting system, and a deeper well. Both subsurface drip irrigation and rainwater harvesting systems are initially expensive to install, but over time the amount of water and money saved by the farm will make up for the extra initial costs. The new well will be 100 feet deep, 60 feet deeper than the existing well, and its location will be strategically located such that the water level is not greatly affected by other pumps. Based on calculations and rainfall statistics in central Texas, the rainwater harvesting system could collect up to 900,000 gallons of water each year, which is more than enough to irrigate the ten acres of crops at Tecolote Farm. This scenario could help the farm to eventually draw the majority of its irrigation water from its rainwater collection tank, and the well water could serve only as a buffer. As less water is draw from the ground, and as more farms and water suppliers adopt this practice, the local aquifers will have a greater opportunity to recharge. To help local farms establish a mutually beneficial business relationship with the residents and business owners of the nearby developments, we recommend surveying restaurants and grocery stores that could purchase fresh produce from the farm. In addition, we recommend searching for venues in the neighborhoods where the farm can sell to residents of the community. This business strategy could help raise awareness of the farms’ and the county’s water issues among the people living and working in the developments. While the problem we hope to solve is specific to Tecolote Farm, its solution could have far reaching benefits. We would ask the committee to not look at this as a simple rescue of a local farm, but rather a technology demonstration that could serve as an example to other farms facing similar situations. In Texas, and other equally dry areas worldwide, there is less water available than there is need for it. New and innovative methods for collection and conservation will be necessary to sustain our current standard of living, and to improve it. Through our solution, Tecolote Farm may serve as a leader in Travis County, moving towards an entirely sustainable model for their business.