REVISED Supplementary Information File

advertisement

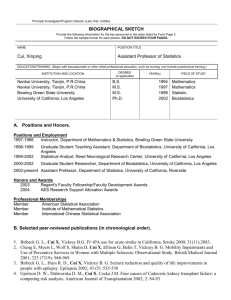

Supporting Information Efficient organic solar cells using copper(I) iodide (CuI) hole transport layers Ying Peng1,2, Nir Yaacobi-Gross2, Ajay K. Perumal2, Hendrik A. Faber2, George Vourlias3, Panos A. Patsalas3, Donal D.C. Bradley2, Zhiqun He1* and Thomas D. Anthopoulos2* 1 Key Laboratory of Luminescence and Optical Information, Ministry of Education, Institute of Optoelectronic Technology, Beijing Jiaotong University, Beijing, 100044, People’s Republic of China Department of Physics and Centre for Plastic Electronics, Blackett Laboratory, Imperial College London, London, SW7 2AZ, U.K. 3 Department of Physics, Laboratory of Applied Physics, Aristotle University of Thessaloniki, GR-54124 Thessaloniki, Greece S1. APS measurements Cube root of PE signal 50 Solution processed CuI 40 30 20 VB = 5.26 eV 10 0 Evaporated CuI 80 Cube root of PE signal 2 60 40 20 VB = 5.05 eV 0 5.6 5.4 5.2 5.0 4.8 4.6 Energy (eV) SI-1 4.4 4.2 Figure S1. APS photoemission data plotted as a function of incident photon energy for solution-processed (top) and evaporated (bottom) films of CuI on ITO-coated glass substrates. S2. XPS and XRD measurements The X-ray Photoelectron Spectra (XPS) were acquired in a KRATOS Axis Ultra DLD system equipped with a monochromated Al K X-ray source, hemispherical sector electron analyzer and a multichannel electron detector. The XPS measurements were performed using a 20 eV pass energy. X-Ray Diffraction (XRD) measurements were acquired in geometry with a two circle powder diffractometer (Ultima+ by Rigaku) using a Cu anode, 40 3/2 I-3d 3/2 Cu-2p 1000 900 800 700 600 500 400 300 200 100 VB I-4p Cu-3p I-4d Si-2s Si-2p I-3p Cu-LMM O-1s I-4s Evaporation Solution Processed C-1s 1/2 CuI Cu-2p I-MNN Electron Intensity (Arb. Units) I-3d 5/2 kV voltage and 30 mA current. 0 Binding Energy(eV) Figure S2. Wide scan XPS spectra with suggested peak identifications; the chemical analysis reported in the manuscript text was based on these data. SI-2 XPS was used to determine the elemental composition of the solution-processed and evaporated CuI films. The elemental composition was determined from the wide scan XPS spectra (Figure S2) considering the peak strength after background subtraction and the corresponding sensitivity factors using the Kratos Vision Software. The characteristic photoelectron lines of I, Cu, and adventitious C were detected in both samples. In addition, the solution processed sample also exhibited peaks assigned to Si and O, that are most likely attributable to pinholes in the CuI films (that expose the underlying glass substrate); a significant void density can also been seen in the AFM images of Fig. 2b. Both samples are found to be deficient in iodine, i.e. [I]/[Cu] ratio < 1 (see Table S1). In particular, the solution-processed sample is more I-deficient, which might explain the apparent difference in the optical absorption compared to the evaporated sample (Fig. 2a). The X-ray diffractograms of the two studied samples are presented in Figure S3. We note that despite their different processing methods, both samples exhibit exclusively peaks of the [111] family of crystal planes [i.e. (111) and (222)], consistent with a predominantly γCuI cubic zinc blende structure. The crystalline a-axis dimension, (see Table S1), was determined from the (111) peak position using the following equation: √3𝜆 𝛼 = 2𝑠𝑖𝑛𝜃 S1 The percentage deviation from the reference value PDF = 0.6051 (±0.0001) nm provided by the JCPDS powder diffraction file (No 06-0246) is determined by: Δ𝛼/𝛼(%) = 100 × (𝛼𝑃𝐷𝐹 − 𝛼)/𝛼𝑃𝐷𝐹 S2 This deviation may be due to the observed iodine deficiency in our samples (it is greater for more deficient solution-processed samples, see Table I) and/or to macroscopic strain. SI-3 XRD Intensity (Arb. Units) (111) CuI Evaporated Experiment Voigt Fit Solution-processed Experiment Voigt Fit (222) 24 25 26 o Angle 2 ( ) 52 53 Figure S3. X-ray diffraction profiles of the (111) and (222) peaks observed for our CuI films along with Voigt fits to the (111) peak data. More detailed structural features of the films were determined by XRD peak fitting [1]. To determine the grain size and degree of micro-strain we fitted the (111) peak profile to a Voigt curve. The deduced Lorentzian broadening WL was introduced into Scherrer’s formula to determine the grain size, while the corresponding Gaussian broadening (WG) was used to estimate the micro-strain (s) through the relation: 𝜀𝑠 = 𝑊𝐺 𝑐𝑜𝑠𝜃 4𝑠𝑖𝑛𝜃 S3 The degree of micro-strain is a measure of the presence of structural defects such as dislocations and grain boundaries. In the case of evaporated CuI films the Voigt fits converge to an almost pure Lorentzian profile (i.e. the Gaussian broadening had a negligibly small value) indicating excellent crystal quality, largely free of defects, along the growth direction. The grain size determined from Scherrer’s formula (21.7 nm) is, within experimental error, equal to the nominal thickness of the film (25 nm). On the other hand, solution processed CuI SI-4 films show a Voigt profile with more significant broadening values for both the Gaussian and Lorentzian broadenings. The determined grain size is slightly smaller than that for evaporated samples and in addition, there is evidence for significant micro-strain. In conclusion, the solution-processed samples do not have the same level of crystal perfection as the evaporated samples. Table S1. Chemical and structural properties of evaporated and spin-coated CuI films. a-axis cell dimension, (nm) Crystalline grain size (nm) Micro-strain (%) 0.6034 0.6031 21.7 18.4 N/A 0.205 Evaporated Solution processed (%) deviation from reference data 0.28 0.33 [I]/[Cu] stoichiometry 0.850 0.734 S3. Electrical characterization of solar cells in the dark Figure S4 shows the dark J-V characteristics of standard and inverted PBDTTPD:PC61BMbased solar cells based on the different HTLs. As can be seen, negligible differences in the characteristics between PEDOT:PSS and CuI(sln) based device can be observed indicating that the latter HTL does not hinder hole injection into the active blend. 2 Current density (mA/cm ) 10 8 6 4 CuI(sln) 2 Inverted cell CuI(eva) 0 PEDOT:PSS 0.0 0.2 0.4 Bias (V) SI-5 0.6 0.8 1.0 Figure S4. J-V characteristics measured in the dark for solar cells based on PEDOT:PSS and CuI(sln) and inverted cells with CuI(eva) as the hole transporting layers (HTLs). All devices were fabricated using PBDTTPD:PC61BM donor : acceptor blend discussed in the main manuscript. SI Reference 1. N. Pliatsikas et al., Surf. Coat. Technol. 257, 63 (2014). SI-6