INSTRUCTIONS TO AUTHORS FOR THE PREPARATION

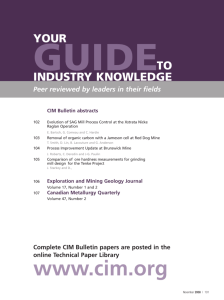

advertisement

GRINDING CIRCUIT SIMULATION REGARDING THE DESIGN OF CRUSHING SYSTEM FOR SAG MILL CIRCULATING LOAD Omid VandGhorbany1, Fardis Nakhaei2, Abbas Sam3 1,3 Department of Mining Engineering, Shahid Bahonar Kerman University, Kerman, P.O. Box 7618868366, Iran 2 Department of Mining & Metallurgical Engineering, Amirkabir University of Technology, Tehran, Iran ABSTRACT The feed rate of Shahr Babak copper complex (Iran) concentrator is 750 t/h. This blended material is feeding to a SAG mill following two parallel ball mills. SAG mill’s product is flowed to a trommel screen that produces two over and under size materials. The screen oversize is circulated into the SAG mill and its undersize is transferred to hydrocyclone for further processes. The average amount of circulating load was measured about 85 t/h. To increase the capacity and improvement of SAG mill operation, it was decided to design a re-crushing system for rejecting load of SAG mill. In order to study how this work should be done, the circuit of this complex was simulated in three states. The simulations were carried out by crushing the circulating load via HGPGR and one cone crusher and the third simulated state was the present circuit of concentrator for comparison. In the simulation, the product of cone crusher was led to SAG mill but that of the HPGR were sent to ball mills to increase the capacity of SAG mill. Eventually the simulations showed that by using HPGR the power of SAG mill reduced from 5346 kW to 4925 kW, while this power was 5065 kW when the circulating load is crushed by cone crusher. Also, the results showed that via feeding the discharge of HPGR to ball mills, it is possible to increase the capacity of comminution circuit, considerably. KEYWORDS Shahr Babak, SAG mill, Trommel screen, HPGR, Power.