MSE 227 HW_6 F10 solutions

advertisement

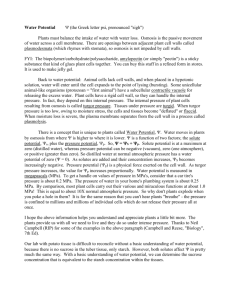

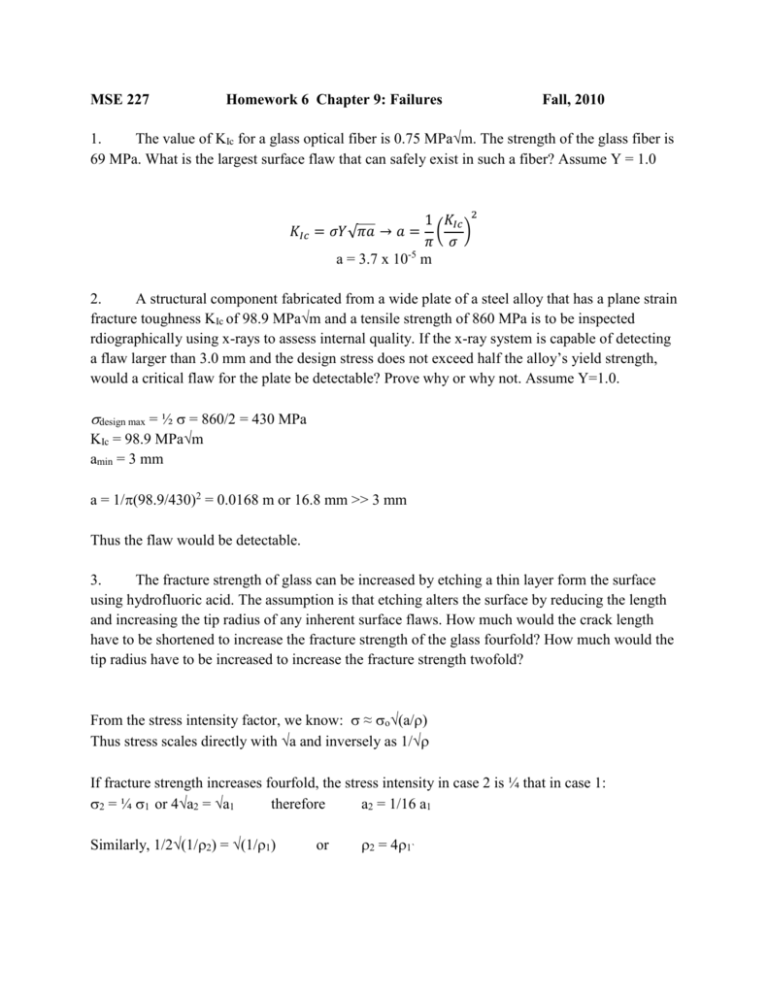

MSE 227 Homework 6 Chapter 9: Failures Fall, 2010 1. The value of KIc for a glass optical fiber is 0.75 MPa√m. The strength of the glass fiber is 69 MPa. What is the largest surface flaw that can safely exist in such a fiber? Assume Y = 1.0 1 𝐾𝐼𝑐 2 𝐾𝐼𝑐 = 𝜎𝑌√𝜋𝑎 → 𝑎 = ( ) 𝜋 𝜎 a = 3.7 x 10-5 m 2. A structural component fabricated from a wide plate of a steel alloy that has a plane strain fracture toughness KIc of 98.9 MPa√m and a tensile strength of 860 MPa is to be inspected rdiographically using x-rays to assess internal quality. If the x-ray system is capable of detecting a flaw larger than 3.0 mm and the design stress does not exceed half the alloy’s yield strength, would a critical flaw for the plate be detectable? Prove why or why not. Assume Y=1.0. design max = ½ = 860/2 = 430 MPa KIc = 98.9 MPa√m amin = 3 mm a = 1/(98.9/430)2 = 0.0168 m or 16.8 mm >> 3 mm Thus the flaw would be detectable. 3. The fracture strength of glass can be increased by etching a thin layer form the surface using hydrofluoric acid. The assumption is that etching alters the surface by reducing the length and increasing the tip radius of any inherent surface flaws. How much would the crack length have to be shortened to increase the fracture strength of the glass fourfold? How much would the tip radius have to be increased to increase the fracture strength twofold? From the stress intensity factor, we know: ≈ o√(a/) Thus stress scales directly with √a and inversely as 1/√ If fracture strength increases fourfold, the stress intensity in case 2 is ¼ that in case 1: 2 = ¼ 1 or 4√a2 = √a1 therefore a2 = 1/16 a1 Similarly, 1/2√(1/2) = √(1/1) or 2 = 41` 4. Estimate the magnitude of the maximum stress that exists at the tip of an internal crack having a tip radius of 2.5 x 10-4 mm and a crack length of 2.5 x 10-2 mm. if the applied tensile stress is 170 MPa. Using: =o[2√(a/)+1] where a = 1.25 x 10-2 mm, = 2.5 x 10-4 mm And o = 170 MPa = 15.14 x o = 2574 MPa If we neglect the additional 1, = 14.14 x o = 2400 MPa In most cases, 2√(a/) >> 1, and it is safe to disregard the 1. 5. The fatigue data for a steel alloy are given as follows: Stress Amplitude Cycles to MPa Failure 470 104 440 3 x 104 390 105 350 3 x 105 310 106 290 3 x 106 290 107 290 108 a. Make an S-N plot (stress amplitude versus logarithm cycles to failure) using the given data. What is the fatigue limit for this alloy? Determine the fatigue lifetimes at stress amplitudes of 415 MPa and 275 MPa. Estimate fatigue strength at 2 x 104 and 6 x 105cycles. b. c. d. SN Curve 500 450 Stress. MPs 400 350 300 250 200 1.00E+03 1.00E+04 1.00E+05 1.00E+06 Cycles (a) Using the curve, (b) fatigue limit = 290 MPa (c) 5 x 104, unlimited (d) 450 MPa, 320 MPa 1.00E+07 1.00E+08