Eco-efficient cements made with activated paper sludge wastes

advertisement

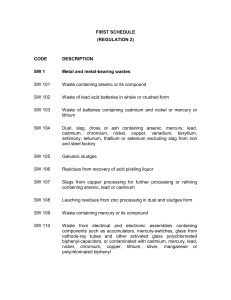

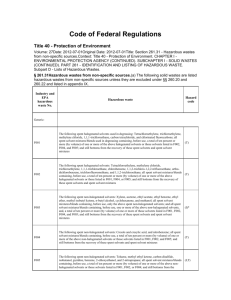

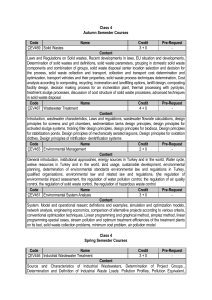

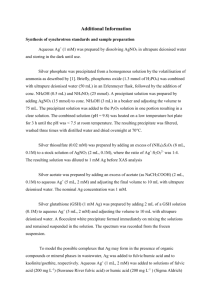

Eco-efficient cements made with activated paper sludge wastes Authors: M. Frías*, I. Vegas, R. Vigil, R. García. (* Corresponding author:mfrias@ietcc.csic.es) The cement manufacturing process, because of its nature, is one of the major industries that release large amounts of greenhouse gases. It is estimated that releases between 800-1000 kg of CO2 per ton of clinker into the atmosphere. One of its priorities is the search for new materials that can be used as active additions, which have a direct impact on reducing gas pollutants. Recently, the Council of Ministers of the EU has adopted a directive that will introduce more stringent limits in order to reduce industrial emissions from 2016, and also wants to improve the health of the citizens as well as environmental protection. According to their intrinsic composition, paper sludge wastes can be used in many different ways such as agriculture, ceramics or even as an alternative combustible. During the last decade, a group of researchers from different Spanish institutions (Instituto Eduardo Torroja CSIC, Tecnalia and Universidad Autónoma de Madrid) have established the scientific, technical and environmental bases for the use of thermally activated paper sludges as pozzolanic additions in order to obtain ecoefficient portland cement manufacture. According to available data in Europe, its said that around 2.5 million tons of paper de-inking sludges are produced annually. These sludges are classified as inert wastes and for this reason, in most of countries are deposited in landfills with consequent environmental and social problems. The chapter of the book address the following concepts Characterization of paper de-inking sludges Activation process and its influence on the mineralogy of the activated products Evaluation of the pozzolanic properties of the products obtained Studies of reaction kinetics in various systems, pozzolan / lime and pozzolan / cement Physical-mechanical behavior of the new cements Aspects of durability