View

advertisement

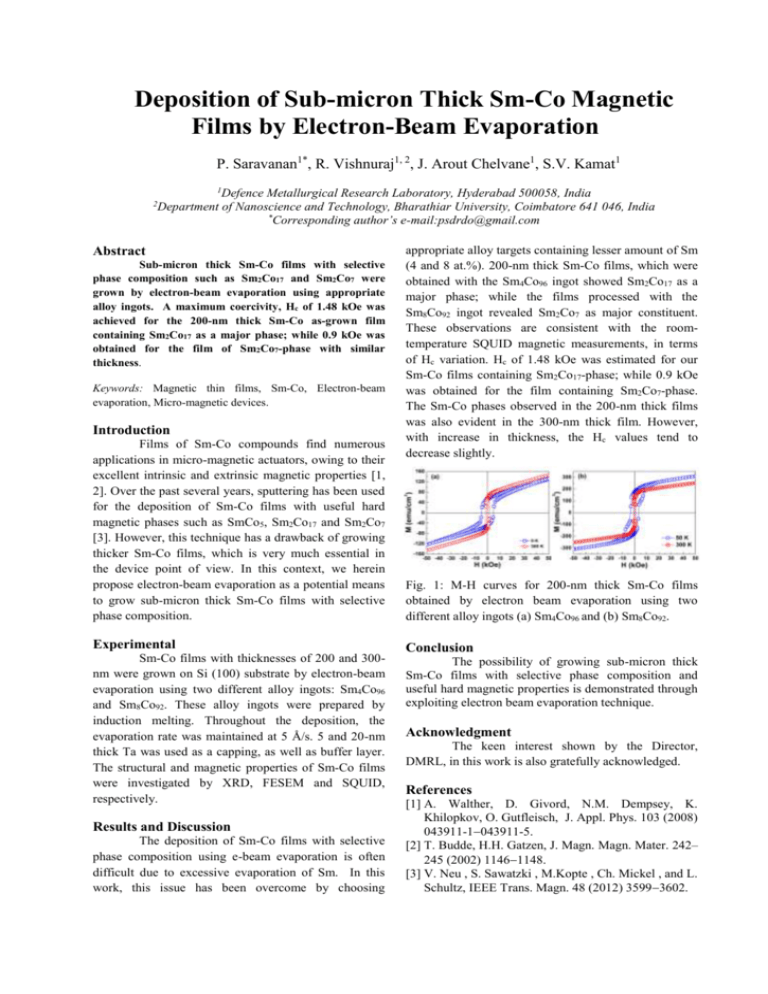

Deposition of Sub-micron Thick Sm-Co Magnetic Films by Electron-Beam Evaporation P. Saravanan1*, R. Vishnuraj1, 2, J. Arout Chelvane1, S.V. Kamat1 1 2 Defence Metallurgical Research Laboratory, Hyderabad 500058, India Department of Nanoscience and Technology, Bharathiar University, Coimbatore 641 046, India * Corresponding author’s e-mail:psdrdo@gmail.com Abstract Sub-micron thick Sm-Co films with selective phase composition such as Sm2Co17 and Sm2Co7 were grown by electron-beam evaporation using appropriate alloy ingots. A maximum coercivity, Hc of 1.48 kOe was achieved for the 200-nm thick Sm-Co as-grown film containing Sm2Co17 as a major phase; while 0.9 kOe was obtained for the film of Sm2Co7-phase with similar thickness. Keywords: Magnetic thin films, Sm-Co, Electron-beam evaporation, Micro-magnetic devices. Introduction Films of Sm-Co compounds find numerous applications in micro-magnetic actuators, owing to their excellent intrinsic and extrinsic magnetic properties [1, 2]. Over the past several years, sputtering has been used for the deposition of Sm-Co films with useful hard magnetic phases such as SmCo5, Sm2Co17 and Sm2Co7 [3]. However, this technique has a drawback of growing thicker Sm-Co films, which is very much essential in the device point of view. In this context, we herein propose electron-beam evaporation as a potential means to grow sub-micron thick Sm-Co films with selective phase composition. Experimental Sm-Co films with thicknesses of 200 and 300nm were grown on Si (100) substrate by electron-beam evaporation using two different alloy ingots: Sm4Co96 and Sm8Co92. These alloy ingots were prepared by induction melting. Throughout the deposition, the evaporation rate was maintained at 5 Å/s. 5 and 20-nm thick Ta was used as a capping, as well as buffer layer. The structural and magnetic properties of Sm-Co films were investigated by XRD, FESEM and SQUID, respectively. Results and Discussion The deposition of Sm-Co films with selective phase composition using e-beam evaporation is often difficult due to excessive evaporation of Sm. In this work, this issue has been overcome by choosing appropriate alloy targets containing lesser amount of Sm (4 and 8 at.%). 200-nm thick Sm-Co films, which were obtained with the Sm4Co96 ingot showed Sm2Co17 as a major phase; while the films processed with the Sm8Co92 ingot revealed Sm2Co7 as major constituent. These observations are consistent with the roomtemperature SQUID magnetic measurements, in terms of Hc variation. Hc of 1.48 kOe was estimated for our Sm-Co films containing Sm2Co17-phase; while 0.9 kOe was obtained for the film containing Sm2Co7-phase. The Sm-Co phases observed in the 200-nm thick films was also evident in the 300-nm thick film. However, with increase in thickness, the Hc values tend to decrease slightly. Fig. 1: M-H curves for 200-nm thick Sm-Co films obtained by electron beam evaporation using two different alloy ingots (a) Sm4Co96 and (b) Sm8Co92. Conclusion The possibility of growing sub-micron thick Sm-Co films with selective phase composition and useful hard magnetic properties is demonstrated through exploiting electron beam evaporation technique. Acknowledgment The keen interest shown by the Director, DMRL, in this work is also gratefully acknowledged. References [1] A. Walther, D. Givord, N.M. Dempsey, K. Khilopkov, O. Gutfleisch, J. Appl. Phys. 103 (2008) 043911-1043911-5. [2] T. Budde, H.H. Gatzen, J. Magn. Magn. Mater. 242– 245 (2002) 11461148. [3] V. Neu , S. Sawatzki , M.Kopte , Ch. Mickel , and L. Schultz, IEEE Trans. Magn. 48 (2012) 35993602.