Custodian URS - Sample

advertisement

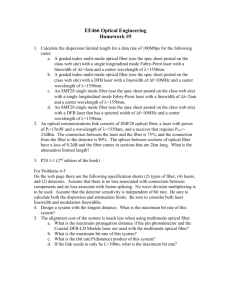

User Requirements Specifications Design and Development of Microfiber based Devices (Microfiber Devices) Telekom Research & Development Sdn. Bhd TMR&D Innovation Centre , Lingkaran Teknokrat Timur, 63000 Cyberjaya, Selangor Darul Ehsan Tel: 603-88839595 Fax: 603-88839599 Requirement Specification (URS) ITNT/TMRNDRESEARCH/RS021/TP Version 3.0 Prepared by: Name : Siti Azlida Ibrahim Post : Technical Leader Date : 9/2/2015 Signature: Reviewed by: Name : Siti Azlida Ibrahim Post : Project Manager Date : 9/2/2015 Signature: Name : Post : Project Advisor Date : Signature: Name : Post : Theme Lead Date : Signature: Approved by: Name : Post : Date : Signature: Date : 24/10/13 Table of Contents 1.Introduction ............................................................................................................................ 3 1.1 1.2 1.3 Objective ................................................................................................................................. 3 Scope........................................................................................................................................ 3 Background ........................................................................................................................... 3 Section 2. Functional Specifications .......................................................................... 4 Section 3. Functional Specifications ......................Error! Bookmark not defined. 1.Introduction 1.1 Objective The objectives of this project is: To design and develop microfiber based optical devices (e.g filters, wavelength converters, sensors, etc) 1.2 Scope This document covers the user requirements specifications (URS) for Microfiber Devices project. The end products of this project will be: Prototype of optical microfiber devices (sensors, filters, wavelength converters) 1.3 Background This project is a continuation of a previous project, “Design, Fabrication and Characterization of Highly Nonlinear Long Silica Microfiber”. In the previous project, long microfibers were successfully fabricated using the built taper rig. This project is to develop optical devices using the fabricated microfibers. 2. Functional Specifications Microfiber is a fiber with smaller diameter that was fabricated by pulling the normal optical fiber while heating up certain area of the fiber. This process produces a microfiber, which is also known as tapered fiber as shown in Figure 1. The pulling speed, temperature, etc will determine the waist diameter, waist length and transition length. These are the research done in the previous project, where the taper rig can be controlled to fabricate a microfiber with specific parameters. Figure 1: Diagram of microfiber fabricated by heating and pulling a normal optical fiber In this project two groups of functional devices will be developed from the fabricated microfibers, which are: 1. Nonlinear devices (wavelength converter ,filters) 2. Sensors (Gas sensors, liquid sensors) Devices based on microfibers have few advantages as compared to conventional optical fibers. They can be more efficient and have much smaller footprints. Light travelling in the microfibers will experience high nonlinearity effect, which makes it suitable to be used for nonlinear devices. Examples of nonlinear devices are wavelength converter, and wavelength filter. Development of microfiber based devices is in line with the direction towards all-optical signal processing in the transmission system, which would eliminate electronic bottle-neck in the future. Example of signal processing in all optical signal regeneration is shown in Figure 2. All optical signal regenerator is shown in Figure 3. Figure 2: All optical signal regeneration Figure 3: All optical signal wavelength converter. High evanescent field surrounding the microfibers will be exploited for sensor applications. Figure 4 shows how microfiber can be used as sensor. By coating the fiber with a sensing layer that is sensitive to a specific target analyte, the change in absorbance of the light is used for sensing parameters. Fiber based sensor has many advantages as compared to conventional electronics sensors including immunity to electromagnetic interference, higher sensitivity, suitable for remote sensing and distributed sensing application. Figure 4: Illustration of microfiber based sensor 3. Stakeholders Key personal 1. Mr Izahar – custodian 2. Siti Azlida Ibrahim – Technical Lead Researchers 1. Assoc. Prof. Dr Zulfadzli Yusoff 2. Prof. Dr. Hairul Azhar Abdul Rashid 3. Prof. Dr. Mohd. Ridzuan Mokhtar 4. Katrina D. Dambul 5. Dr. A.S.M. Mukter-uz- Zaman Collaborators 1. Prof. Dr. Mohd. Adzir Mahdi – UPM 2. Dr. Mohd. Hanif Yaacob – UPM 3. Dr. Norizah Abdul Rahman - UPM 3. Project Schedule & Milestone