aic14098-sup-0001-suppinfo

advertisement

Supplemental Material: Mathematical model (SI system)

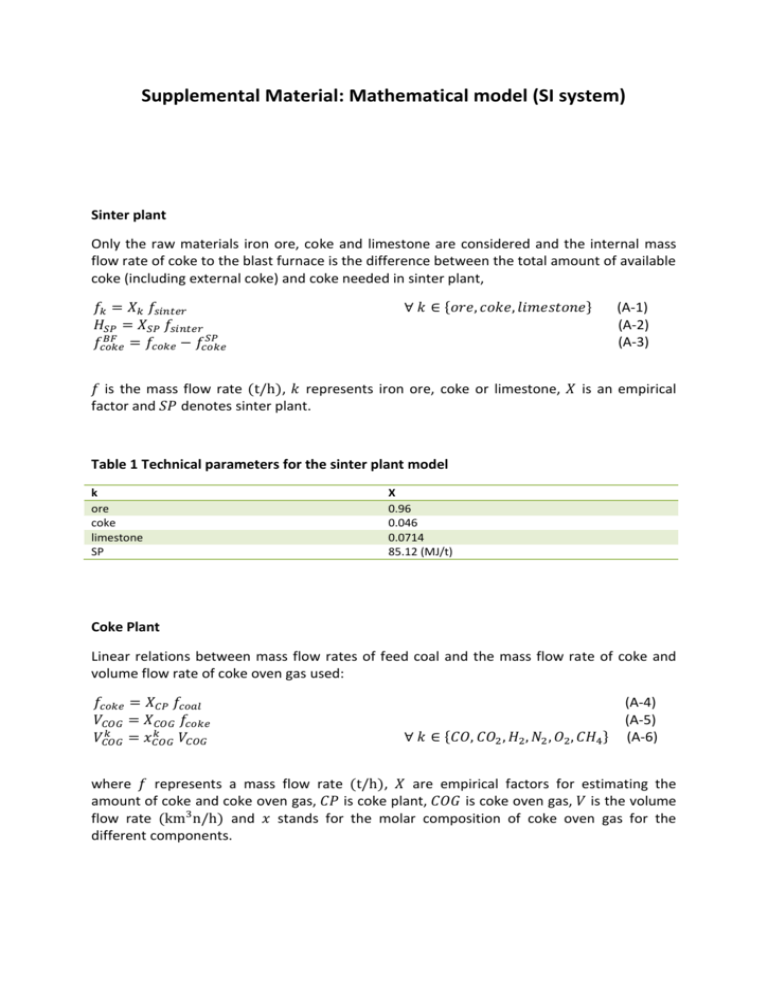

Sinter plant

Only the raw materials iron ore, coke and limestone are considered and the internal mass

flow rate of coke to the blast furnace is the difference between the total amount of available

coke (including external coke) and coke needed in sinter plant,

𝑓𝑘 = 𝑋𝑘 𝑓𝑠𝑖𝑛𝑡𝑒𝑟

𝐻𝑆𝑃 = 𝑋𝑆𝑃 𝑓𝑠𝑖𝑛𝑡𝑒𝑟

𝑆𝑃

𝐵𝐹

𝑓𝑐𝑜𝑘𝑒

= 𝑓𝑐𝑜𝑘𝑒 − 𝑓𝑐𝑜𝑘𝑒

∀ 𝑘 ∈ {𝑜𝑟𝑒, 𝑐𝑜𝑘𝑒, 𝑙𝑖𝑚𝑒𝑠𝑡𝑜𝑛𝑒}

(A-1)

(A-2)

(A-3)

𝑓 is the mass flow rate (t/h), 𝑘 represents iron ore, coke or limestone, 𝑋 is an empirical

factor and 𝑆𝑃 denotes sinter plant.

Table 1 Technical parameters for the sinter plant model

k

ore

coke

limestone

SP

X

0.96

0.046

0.0714

85.12 (MJ/t)

Coke Plant

Linear relations between mass flow rates of feed coal and the mass flow rate of coke and

volume flow rate of coke oven gas used:

𝑓𝑐𝑜𝑘𝑒 = 𝑋𝐶𝑃 𝑓𝑐𝑜𝑎𝑙

𝑉𝐶𝑂𝐺 = 𝑋𝐶𝑂𝐺 𝑓𝑐𝑜𝑘𝑒

𝑘

𝑘

𝑉𝐶𝑂𝐺

= 𝑥𝐶𝑂𝐺

𝑉𝐶𝑂𝐺

∀ 𝑘 ∈ {𝐶𝑂, 𝐶𝑂2 , 𝐻2 , 𝑁2 , 𝑂2 , 𝐶𝐻4 }

(A-4)

(A-5)

(A-6)

where 𝑓 represents a mass flow rate (t/h), 𝑋 are empirical factors for estimating the

amount of coke and coke oven gas, 𝐶𝑃 is coke plant, 𝐶𝑂𝐺 is coke oven gas, 𝑉 is the volume

flow rate (km3 n/h) and 𝑥 stands for the molar composition of coke oven gas for the

different components.

Table 2 Technical parameters for the coke plant model

k

CO

CO2

H2

O2

N2

CH4

x

0.0528

0.0177

0.5807

0.0014

0.0646

0.2828

COG

CP

0.3197

0.6742

Hot Stoves

The volume flow rate of blast and energy needed for the hot stoves is estimated by an

efficiency factor of 0.6885. The heat is assumed to be generated by using internal fuel (off

gases) and/or external oil supply.

𝐵𝐹

𝑉 = 𝑉𝑏𝑙𝑎𝑠𝑡

𝑜𝑢𝑡

𝑖𝑛

∆𝐻𝐻𝑆 = 𝜂𝐻𝑆 (𝐻𝐻𝑆

− 𝐻𝐻𝑆

)

𝐵𝐹

𝑉𝑂2 = 𝑉𝑏𝑙𝑎𝑠𝑡

𝑒𝑛𝑟𝑖𝑐ℎ𝑚𝑒𝑛𝑡

(A-7)

(A-8)

(A-9)

where 𝐵𝐹 is the blast furnace, 𝐻𝑆 is hot stoves, ∆𝐻 is the difference between the

enthalpies, 𝐻 is the enthalpy (of input and output streams) and 𝜂 stands for the hot stove

efficiency factor.

Basic oxygen furnace

The production of liquid steel is taken to be proportional to the amount of hot metal and

scrap. We assumed 50% recovery of BOF off gases with fixed composition of CO and CO2 of

0.9 and 0.1, respectively.

𝐵𝐹

𝑓𝑙𝑠 = (1.1453). 𝑓𝐻𝑀

𝐵𝑂𝐹

𝐵𝐹

𝑉𝐵𝑂𝐹𝐺

= (0.0415). 𝑓𝐻𝑀

𝐵𝐹

𝑉𝑂𝐵𝑂𝐹

= (0.4562) . 𝑓𝐻𝑀

2

𝐵𝑂𝐹

𝐵𝐹

𝑓𝑆𝑐𝑟𝑎𝑝

= (0.25). 𝑓𝐻𝑀

𝐵𝑂𝐹

𝐵𝐹

𝑓𝑙𝑖𝑚𝑒𝑠𝑡𝑜𝑛𝑒

= (0.06657). 𝑓𝐻𝑀

(A-10)

(A-11)

(A-12)

(A-13)

(A-14)

where 𝑓 is mass flow rate (t/h), 𝑙𝑠 is liquid steel, 𝐻𝑀 is hot metal, 𝐵𝑂𝐹 is basic oxygen

furnace, 𝐵𝑂𝐹𝐺 is basic oxygen furnace off gases.

Power Plant

The power plant is modeled in a way which produces utility requirements for the whole

plant and external electricity and district heat based on demand or price as byproduct. The

internal fuels (off gases) and oil is used as feedstock. The technical data is presented below:

Table 3 Data for power plant model

Efficiency

Turbine

[Steam, 75 bar 5 bar]

Production of District Heat

[Heat Exchanger, Tout=60 ’C]

Production of electricity

[Generator]

η

0.79

0.9

0.95

Blast Furnace

The general model for the blast furnace is described in the Appendix of ref. 8. For the sake of

simplicity a surrogate model based on PLS and Kriging has been used in the present study

BF

𝑍𝑚

= 𝐴1,𝑚 + ∑ 𝐴2,𝑚,𝑛 𝑋𝑛BF

49

(A-15)

𝑛

BF

2 )

𝑍̂𝑚

= 𝜇𝑚 + ∏ 𝛾𝑠𝑗 exp(−𝜃𝑚𝑛 𝑑𝑛𝑠

(A-16)

𝑠=1

2

𝑑𝑛𝑠

= (𝑋𝑛BF − 𝑤𝑠𝑛 )

(A-17)

where 𝐴1,𝑚 and 𝐴2,𝑚 are regression coefficients, 𝑋𝑛BF (n = 1,..,5) stands for the hot metal

production (t/h), specific oil rate, pellet rate (kg/t hm ), blast oxygen content (%), or blast

temperature (C) that are the five inputs to the blast furnace model. The fifteen outputs

BF

𝑍̂𝑚

(𝑚 = 1, … ,15) in the surrogate model are the specific coke rate (kg/t hm ), volume flow

rate of top gases (km3 n/h), composition of top gases (H2 , N2 , CO2 , CO), top gas

temperature (C), sinter rate (kg/t hm ), blast volume flow rate (m3 n/h), (raceway) flame

temperature (C), burden residence time (h), bosh gas volume (km3 n/h), limestone rate

(kg/t hm ), quartzite rate (kg/t hm ) and slag rate (kg/t hm ), 𝜇𝑚 is the generalized least

2

squares estimate for the polynomial term, 𝜃𝑚𝑛 is the correlation function parameters, 𝑑𝑛𝑠

=

BF

(𝑋𝑛 − 𝑤𝑠𝑛 ) are the differences between a point and the design sites 𝑤𝑠𝑛 , and 𝑠 is the

number of random points that have been generated by the Latin hypercube method. The

Kriging method has been used to estimate the last three terms based on s = 49 random input

points.

Table 4 Regression coefficients after scaling of the blast furnace-PLS model

Coke rate

Top

Gas

Volume

CO

Composition

O2

Composition

H2

Composition

N2

Composition

Top

Gas

Temp.

Sinter Rate

O2 Volume

flow rate

Blast Volume

Rate

Flame

Temperature

Residence

time

Basicity

Slag

flow

Rate

Bosh

Gas

Volume

Hot Metal

Oil Rate

-0.005014

1.4760350

-1.025237

0.1237624

-0.0000019

Pellet Rate

Blast

Temperature

-0.10781

-0.06647

A1

-0.009983

-0.004576

O2

Enrichment

-0.278994

-5.187665

-0.000173

-0.00001

0.005796

-0.00000407

0.1058

0.0000009

-0.000182

0.000018

0.0054725

0.00003593

0.0578

0.0000033

0.0004412

-0.00000088

0.0013414

0.00001247

-0.0349

-0.0000023

-0.000085

-0.00000716

-0.0126100

-0.00004434

0.8712

0.0175255

1.095010

-0.02639143

-16.06648

-0.16139

657.704

0.0001598

76.819234

-0.000373

7.218492

-1.080164

-0.529055

0.002875

1267.9047

0.00001888

-4.832905

1572.14

30928.3

957.52657

54.53718

-5.095824

-5167.110

-56.48740

192363.2

-0.0193695

-3.326163

-0.016224

36.97700

0.624802

890.11

-0.0493425

0.012907

0.000237

0.004898

0.001405

11.162

0.0000080

-0.0224216

0.0006239

-0.021151

0.00004875

-0.117201

0.000327

-0.415930

-0.00001126

-0.0128152

0.9652

306.777

1354.9086

234.06044

-6.650835

-5182.449

-73.412888

191684.33

581.644

195.454

Membrane Process

The operational pressure and molar flow rate (𝐤𝐦𝐨𝐥/𝐡) of the membrane process is

estimated by

𝑙𝑜𝑤

𝑃𝑀𝐸𝑀

ℎ𝑖𝑔ℎ

𝑃𝑀𝐸𝑀

𝐹

=(

𝑦𝐻2𝑀𝐸𝑀

𝑝

𝑦𝐻2𝑀𝐸𝑀

𝑝

)(

𝐹

1 − 𝜁𝐻𝑀𝐸𝑀

2

𝐹

1 − 𝑦𝐻2𝑀𝐸𝑀 𝜁𝐻𝑀𝐸𝑀

2

)

(A-18)

𝑓𝐻2𝑀𝐸𝑀 = 𝜁𝐻𝑀𝐸𝑀

𝑓𝐻2𝑀𝐸𝑀

2

(A-19)

𝑝

𝑓𝑘 𝑀𝐸𝑀

𝐹

𝐹

𝛼{𝑘⁄𝐻2 } 𝜁𝐻𝑀𝐸𝑀

𝑦𝑘 𝑀𝐸𝑀 𝑓𝐻2𝑀𝐸𝑀

2

=

𝐹

𝑦𝐻2𝑀𝐸𝑀

𝑏𝑝𝑀𝐸𝑀

𝑓𝐻2

[2 −

𝜁𝐻𝑀𝐸𝑀

2

(A-20)

𝑝

𝑙𝑜𝑤

𝑦𝐻2𝑀𝐸𝑀 𝑃𝑀𝐸𝑀

−

]

−

2

[

] (1 − 𝛼{𝑘⁄𝐻2 } )

𝐹

ℎ𝑖𝑔ℎ

1 − 𝑦𝐻2𝑀𝐸𝑀 𝜁𝐻𝑀𝐸𝑀

𝑃

𝑀𝐸𝑀

2

𝛼(𝑘⁄𝐻2 ) 𝜁𝐻𝑀𝐸𝑀

2

𝐹

= (1 − 𝜁𝐻𝑀𝐸𝑀

)𝑓𝐻2𝑀𝐸𝑀

2

(A-21)

𝑏𝑝𝑀𝐸𝑀

𝑓𝑘

𝐹

𝑝

= 𝑓𝑘 𝑀𝐸𝑀 − 𝑓𝑘 𝑀𝐸𝑀

(A-22)

ℎ𝑖𝑔ℎ

𝑃𝑀𝐸𝑀

𝐹

𝑝

where

and

are the product and feed stream pressures, 𝑦𝐻2𝑀𝐸𝑀 and 𝑦𝐻2𝑀𝐸𝑀 are

the mole fraction of hydrogen in feed and in the product streams and 𝜁𝐻𝑀𝐸𝑀

is membrane

2

𝑝𝑀𝐸𝑀

hydrogen product recovery, 𝑓𝐻2

is the molar flow rate of hydrogen in the product stream,

𝑝𝑀𝐸𝑀

𝑏𝑝

𝑓𝑘

is the molar flow rate of other components available in the product stream, 𝑓𝐻2 𝑀𝐸𝑀 is

𝑏𝑝

the molar flow rate of hydrogen in the byproduct, 𝑓𝑘 𝑀𝐸𝑀 is the molar flow rate of other

𝑙𝑜𝑤

𝑃𝑀𝐸𝑀

components in the byproduct stream and 𝛼{𝑘⁄𝐻2 } is the ratio of permeability coefficient of

other components available in the stream to hydrogen.

Table 5 Permeability coefficient for components in stream

Component

CO

CH4

CO2

H2

O2

N2

Permeability

2.4

2.3

38

55

8.3

1.4

Pressure Swing Adsorption Process

The operational pressure and molar flow rate (kmol/h) are expressed as

𝑙𝑜𝑤

𝑃𝑃𝑆𝐴

ℎ𝑖𝑔ℎ

𝑃𝑃𝑆𝐴

𝐹

= 𝑦𝐻2𝑃𝑆𝐴 (1 −

𝑝

𝑅𝑃𝑆𝐴

)

1 − 𝛽𝑃𝑆𝐴

(A-23)

𝐹

𝑓𝐻2𝑃𝑆𝐴 = 𝑅𝑃𝑆𝐴 𝑓𝐻2𝑃𝑆𝐴

𝑏𝑝𝑃𝑆𝐴

𝑓𝐻2

𝑏𝑝𝑃𝑆𝐴

𝑓𝑘

𝐹

(A-24)

𝑝

= 𝑓𝐻2𝑃𝑆𝐴 − 𝑓𝐻2𝑃𝑆𝐴

(A-25)

𝐹

= 𝑓𝑘 𝑃𝑆𝐴

(A-26)

ℎ𝑖𝑔ℎ

𝑙𝑜𝑤

where 𝑃𝑃𝑆𝐴

and 𝑃𝑃𝑆𝐴 are the low and high absolute pressure of the pressure swing cycle,

𝐹𝑃𝑆𝐴

𝑦𝐻2 is the mole fraction of the hydrogen in the feed, 𝑅𝑃𝑆𝐴 is the product recovery and βPSA

𝑝

𝐹

is the adsorbent selectivity value, 𝑓𝐻2𝑃𝑆𝐴 is the molar flow rate of the product stream, 𝑓𝐻2𝑃𝑆𝐴

𝑏𝑝𝑃𝑆𝐴

is the molar flow rate of hydrogen in the feed stream, 𝑓𝐻2

𝑏𝑝

𝑓𝑘 𝑃𝑆𝐴

is the molar flow rate of

hydrogen in the byproduct stream and

is the molar flow rate of other components in

the byproduct stream. In practice the value of the hydrogen recovery is less than 0.92 and

for the adsorbent selectivity would be greater than 0.02.

Reactors

The molar flow rates for the gas reforming units are calculated by (linear) mass balances for

fixed conversion reactor with NR parallel reactions for each component, 𝑘, and can be

expressed as

𝑁𝑅

𝑓𝑝𝑘

=

𝑓𝐹𝑘

+ ∑ 𝛾𝑟𝑘 𝑥𝑟 𝑓𝐹𝑙(𝑟)

(A-27)

𝑟=1

where 𝑟 is the number of reaction, 𝑙(𝑟) is the limiting component, 𝛾𝑟𝑘 is the stoichiometric

coefficients which is positive, negative and zero for product, reactant and inert components

and 𝑥𝑟 is the fraction converted per pass based on limiting reactant.

Table 6 operation condition for different gasification process

Reactor

SMR

CDR

POR

LPMEOH

GPMEOH

Operational condition

CH4/H2O=3.681, P=20 bar, T=1153-1300 K

𝑆𝑀𝑅

𝑆𝑀𝑅

𝑥𝐶𝐻

= 81.46, 𝑥𝐶𝑂

= 40.2

4

CH4/CO2=1, P=1 bar, T=1143-1313 K

𝒙𝑪𝑫𝑹

𝑪𝑯𝟒 = 𝟎. 𝟗𝟎

CH4/O2=2, P=1 bar, T=1073-1473 K

𝒙𝑷𝑶𝑹

𝑪𝑯𝟒 = 𝟎. 𝟗𝟓

H2/CO≥2, P=50 bar, T=523 K

𝒙𝑳𝑷𝑴𝑬𝑶𝑯

= 𝟖. 𝟗, 𝒙𝑳𝑷𝑴𝑬𝑶𝑯

= 𝟑𝟎. 𝟔

𝑪𝑶𝟐

𝑪𝑶

H2/CO≥2, P=50 bar, T=533 K

𝒙𝑮𝑷𝑴𝑬𝑶𝑯

= 𝟗𝟓, 𝒙𝑮𝑷𝑴𝑬𝑶𝑯

= 𝟗𝟓

𝑪𝑶𝟐

𝑪𝑶

Compressors

The reference case of the compressor is assumed to operate isentropically, and the true

operation is estimated with adiabatic, motor drive and mechanical efficiencies of 𝜂𝑎𝑑 = 0.9,

𝜂𝑚𝑑 = 0.9 and 𝜂𝑚𝑒𝑐ℎ = 0.85, respectively,

𝑇𝑜𝑢𝑡

𝑃𝑜𝑢𝑡 (𝛾̅−1)⁄𝛾̅

=(

)

𝑇𝑖𝑛

𝑃𝑖𝑛

∑𝑘 𝑓𝑘 (𝐻𝑜𝑢𝑡,𝑘 − 𝐻𝑖𝑛,𝑘 )

𝑊𝑐𝑜𝑚𝑝 =

𝜂𝑎𝑑 𝜂𝑚𝑑 𝜂𝑚𝑒𝑐ℎ

𝑓𝑖𝑛,𝑐𝑜𝑚𝑝 = 𝑓𝑜𝑢𝑡,𝑐𝑜𝑚𝑝

(A-28)

(A-29)

(A-30)

where 𝑇out and 𝑇in are the outlet and inlet absolute temperatures, 𝑃out and 𝑃in are the

outlet and inlet pressures, 𝛾̅ is the average of specific heat ratio of the components in

question and 𝑊𝑐𝑜𝑚𝑝 is the compressor work.

Separation columns

For distillation columns the composition of component in product is specified. The

operational condition is presented in Table 7. The energy balance is expressed as

𝛥𝐻𝑟𝑒𝑏. = 𝛥𝐻𝑐𝑜𝑛𝑑. + 𝛥𝐻𝑠𝑒𝑛𝑠𝑖𝑏𝑙𝑒

(A-31)

𝛥𝐻𝑐𝑜𝑛𝑑. = ∑𝑘=𝑐𝑜𝑚𝑝𝑜𝑛𝑒𝑛𝑡𝑠 𝑖𝑛(𝑅̅ + 1) 𝑓𝑘 𝐻𝑘𝑉

(A-32)

𝑑𝑖𝑠𝑡𝑖𝑙𝑙𝑎𝑡𝑒 𝑠𝑡𝑟𝑒𝑎𝑚

𝛥𝐻𝑠𝑒𝑛𝑠𝑖𝑏𝑙𝑒 =

∑

𝑓𝑘 𝐶𝑃𝑘 𝛥𝑇𝑠𝑒𝑛𝑠𝑖𝑏𝑙𝑒

(A-33)

𝑘=𝑐𝑜𝑚𝑝𝑜𝑛𝑒𝑛𝑡𝑠 𝑖𝑛

𝑑𝑖𝑠𝑡𝑖𝑙𝑙𝑎𝑡𝑒 𝑠𝑡𝑟𝑒𝑎𝑚

𝑘

𝑘

𝑓𝑝𝑟𝑜𝑑𝑢𝑐𝑡

= 𝜁 𝑘 𝑓𝑓𝑒𝑒𝑑

𝑘

𝑘

𝑓𝑏𝑜𝑡𝑡𝑜𝑚

= (1 − 𝜁 𝑘 )𝑓𝑓𝑒𝑒𝑑

(A-34)

(A-35)

where Δ𝐻𝑐𝑜𝑛𝑑. is the enthalpy change to condense the distillate product (kJ/mol), 𝑅̅ is the

reflux ratio, 𝐻𝑘𝑉 is the heat of vaporization at given temperature (kJ/mol), 𝐶𝑃̅ 𝑘 is the specific

heat capacity of the distillate component (kJ/(mol · K)), Δ𝑇𝑠𝑒𝑛𝑠𝑖𝑏𝑙𝑒 is difference of boiling

point of distillate product and feed temperature (K) and 𝜁 is the split fraction of component

in each stream.

Table 7 Operational condition for each separation column

Separation Column

MEOH

DME

GSP

WSP

TSA

COPure

Operational condition

P=3.4 bar, T=318 K

𝜁 𝑚𝑒𝑡ℎ𝑎𝑛𝑜𝑙 = 99.9, R=1.5

P=11.2 bar, T=318 K

𝜁 𝑚𝑒𝑡ℎ𝑎𝑛𝑜𝑙 = 1, R=20

P=11.2 bar, T=318 K

𝜁𝑔𝑎𝑠𝑒𝑠 = 1

P=20 bar, T=383 K

𝜻𝒘𝒂𝒕𝒆𝒓 = 𝟏

P=1 bar,T=273-573K

𝜁 𝐶𝑂 = 0.99

Low P,T

𝜁 𝐶𝑂 = 0.98

Mixer and Splitter units

For mixers and splitter units, linear mass balance is considered for input(s) and output(s)

𝑘

𝑘

𝑓𝑚𝑖𝑥𝑒𝑟

= ∑ 𝑓𝑖𝑛,𝜄

𝜄

(A-36)

𝑘

𝑓𝑠𝑝𝑙𝑖𝑡𝑡𝑒𝑟,𝜄

= 𝜁𝜄 𝑓𝑖𝑛𝑘

(A-37)

where 𝜄 is the number of streams, k is the components and 𝜁 is the specified fraction for

each output stream.

Enthalpy analysis

For all considered units in polygeneration system and carbon capturing and sequestration,

the difference between input and output enthalpies is calculated by

𝑇2

𝑇3

𝑇4

𝐵5𝑘

(A-38)

𝐻𝑘 − 𝐻𝑘,298 = 𝐵1𝑘 𝑇 + 𝐵2𝑘 ( ) + 𝐵3𝑘 ( ) + 𝐵4𝑘 ( ) − (

)

2

3

4

𝑇

+ 𝐵6𝑘 − 𝐵7𝑘

where 𝑇 is temperature in 10−3 K, 𝐻𝑘 is the standard enthalpy in kJ/mol, and 𝐵𝑘 are the

parameters obtained from NIST Chemistry Web book. The energy efficiency of heat

exchangers is assumed to be 0.7.

Table 8 Coefficients in enthalpy estimation

k

CO

CO2

H2

O2

O2

N2

N2

CH4

H2O

B1

25.56

24.99

33.066

31.32

30.032

28.98

19.505

-0.703

30.092

B2

6.096

55.19

-11.363

-20.23

8.77

1.854

19.887

108.477

6.8323

B3

4.05

-33.69

11.43

57.86

-3.988

-9.647

-8.598

-42.521

6.7934

B4

-2.67

7.95

-2.77

-36.50

0.788

16.635

1.369

5.862

-2.5344

B5

0.131

-0.14

-0.158

-0.0073

-0.741

0.00012

0.527

0.678

0.0843

B6

-118.00

-403.61

-9.98

-8.903

-11.324

-8.672

-4.935

-76.843

-250.88

B7

-110.52

-393.52

0

0

0

0

0

-74.873

-241.82

T

298-1200

298-1200

298-1000

100-700

700-2000

100-500

500-2000

298-1300

500-1700

Objective Function

The net present value (NPV) of the project is estimated by

𝑁𝑃𝑉 = − (1 −

𝐶𝐼 = 𝐶𝐼 𝑏𝑎𝑠𝑖𝑐 (

𝜆 1

1

1

1

∙ ∙ (1 −

)) 𝐶𝐼 + ∙ (1 −

) 𝑁𝑃

𝜃

𝑑𝑝

𝜃𝑑𝑝 𝛿

𝛿

(1 + 𝛿)

(1 + 𝛿)𝜃𝑙𝑝

𝑓

𝑓 𝑏𝑎𝑠𝑖𝑐

)

𝑁𝑃 = 𝐶𝑜𝑠𝑡𝑓𝑒𝑒𝑑𝑠𝑡𝑜𝑐𝑘 − 𝑃𝑟𝑖𝑐𝑒𝑝𝑟𝑜𝑑𝑢𝑐𝑡𝑠 + 𝐶𝑜𝑠𝑡𝑒𝑚𝑖𝑠𝑠𝑖𝑜𝑛 𝑎𝑛𝑑 𝑠𝑒𝑞𝑢𝑒𝑠𝑡𝑟𝑎𝑡𝑖𝑜𝑛

(A-39)

(A-40)

(A-41)

where 𝐶𝐼 is the total Capital Investment cost of equipment for gasification, carbon capturing

and sequestration and methanol units, which are expressed by a linear approximation with

fixed cost charge of the Guthrie’s Modular Method with cost update factor for 2010, and NP

is the annual Net Profit of the integrated system, 𝜆 = 40% is tax rate, 𝜃𝑑𝑝 = 30 and 𝜃𝑙𝑝 =

10 years life and depreciation time of project and 𝛿 = 12% is the annual discount rate.