The Chemistry of Biodiesel

advertisement

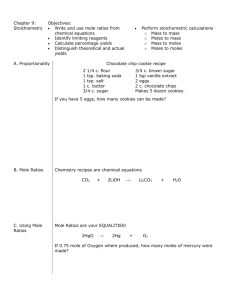

The Chemistry of Biodiesel - Part 1 Fats and Oils Biodiesel is made from vegetable oils and animals fats. Technically, the difference between an oil and a fat is that an oil is liquid at room temperature while a fat is solid. However, both fats and oils, whether from animals or plants, have the same basic structure: a “backbone” composed of a glycerin molecule (also called glycerol) attached to three “tails” composed of fatty acids. This molecule is known as a triglyceride. There is a wide variety of oils and fats, and they differ only in the make-up of their fatty acid tails. Common vegetable oils such as soybean oil, canola oil, or peanut oil, are actually mixtures of triglycerides with different types of fatty acid tails. As we will see, biodiesel fuel properties vary with the make-up of these fatty acid tails. The composition of a triglyceride is presented below. Note that the glycerin backbone is composed for 3 carbons. The fatty acid tail can be composed of as little as a half-dozen carbons to as long as a couple dozen carbons. As triglyceride molecules interact with each other, the fatty acid tails tend to “tangle”. This increases viscosity (thickness). In fats, this interaction increases to the point of solidifying the fat at room temperature. Triglycerides burn well in a diesel engine, but their viscosity causes problems in fuel lines and fuel injectors. To make a good diesel fuel, viscosity must be reduced. Biodiesel Biodiesel fuel is essentially the individual fatty acid tails (with a small modification) separated from the glycerin backbone. Pictured below is a typical biodiesel molecule. Note how similar it is to a typical diesel fuel molecule. Typical biodiesel molecule Typical diesel molecule Note how both are basically a chain of about 16 carbons surrounded by hydrogens. Biodiesel differs only in a structure at one end known as an “ester.” The ester has a single carbon beyond the oxygen, so it is known as a “methyl ester.” This is why biodiesel is known chemically as “fatty acid methyl ester” or FAME. The biodiesel molecule, freed from the glycerin backbone, is less viscous and burns very well in a diesel engine. Unlike diesel, the ester end makes it much less toxic and much more biodegradable. Making Biodiesel To make biodiesel (FAME) we must separate the fatty acid tail from the triglyceride and then add the ester end. This actually occurs in essentially one step, known as “trans-esterification.” A catalyst, typically sodium hydroxide (NaOH) or potassium hydroxide (KOH), is mixed with methanol (MeOH) to produce a mixture known as methoxide. (Remember that OH in an inorganic salt is a base, while OH in an organic molecule is an alcohol, a mild acid). Together, this mixture can remove the fatty acid tail from a triglyceride molecule and add an ester end to it. The methanol is consumed, but the catalyst is not. Heat is generally added to accelerate the reaction. For simplicity, R is used to represent the fatty acid carbon chain. In addition to producing biodiesel, the reaction liberates glycerol. These two molecules have different polarities and different densities, so they separate after formation. Biodiesel, with its long hydrocarbon chain, is relatively non-polar and less dense, so it tends to float to the top. Glycerin, with its three alcohol (OH) groups, is much more polar and dense, and sinks to the bottom. The glycerin can then be drained away, leaving the biodiesel. In this image of a simple biodiesel reaction conducted in a 2L bottle, you can clearly see the dark glycerin at the bottom and the lighter biodiesel floating on top. Stoichiometry How much of the reactants do we need to add? And how much biodiesel and glycerin will we produce? We use stoichiometry to answer this question. Looking back at the biodiesel reaction equation above, it is clear that one triglyceride molecule releases three fatty acid tails, which become three molecules of biodiesel. So a whole bunch of triglyceride molecules (a “mole”*) produces three-times as many molecules (3 moles) of biodiesel. Also note that it takes three methanol (MeOH) molecules to convert one triglyceride to three biodiesel molecules. Each triglyceride molecule will ultimately become one glycerin molecule. Thus one mole of triglyceride needs three moles of MeOH to make three moles of FAME and one mole of glycerin. 1 mole oil + 3 moles MeOH = 3 moles FAME + 1 mole glycerin Note, however, that this reaction is reversible – the glycerin and FAME can combine to recreate MeOH and triglyceride. Ultimately, the reaction reaches equilibrium where you have some of each of the molecules present. This is a problem if our goal is to make as much FAME as possible. To push the reaction to make more FAME, we can increase the amount of MeOH we add. Typically, we double the amount of MeOH to 6 moles for every 1 mole of triglyceride. 1 mole oil + 6 moles MeOH = 3 moles FAME + 1 mole glycerin + 3 moles MeOH This is typically sufficient to push the reaction essentially all the way to the right, with only trace quantities of oil left. The downside is that there are now 3 moles of unreacted MeOH mixed with our products. Getting the MeOH out is a challenge we’ll address later. What about the catalyst? How much should we add? Because the catalyst is not consumed, we can’t use stoichiometry to answer this question. Instead, experience demonstrates how much additional catalyst speeds up the reaction. In this case, experience shows we should add about ! moles of catalyst for every one mole of oil. Remember that the catalyst remains in the products and will have to be removed. 1 mole oil + 6 moles MeOH + ! moles catalyst = 3 moles FAME + 1 mole glycerin Determining the weight of each reactant to add simply requires knowing the molecular weight (how much a mole of each substance weighs). We’ll take that step when you produce bench-scale biodiesel. (* recall that through the work of Avagadro and others, we now define a “whole bunch of molecules” as 6.02 x 1023 molecules, or a “mole”.)