300715133806AbstractforSusChemE

advertisement

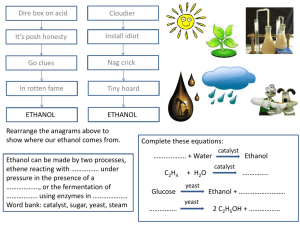

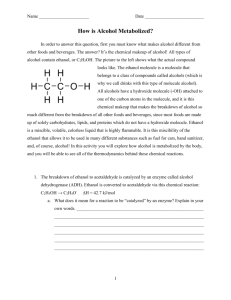

Gas phase oxidation of aqueous ethanol using gold supported cerium oxide catalyst Paresh H. Rana1, Parimal A. Parikh2* 1 Department of Chemical Engineering, Government Engineering College, Bhuj 370001 2 Department of Chemical Engineering, S.V. National Institute of technology, Surat 395007 E-mail:- ranaph78@gmail.com1, parimal.svr@gmail.com2* 1. Introduction: The constant exhaustion and uneven price of the available fossil resources implies new challenges to the future chemical industries, as majority of the (>90%) all carbonaceous chemicals are produced from oil. The product derived from the fossil fuels depends on the cost of fuels.1 Biomass can be a useful alternative for the production of high value commodity chemicals and fuels. Bioethanol, along with increased water content, is now being considered as a key renewable chemical raw material that is alternatives to hydrocarbons. The increase in fundamental studies devoted to investigating the selective conversion of ethanol into added value products like acetic acid, acetaldehyde, acetone etc. 2At the end of 2013 ethanol production reached to 87.2 billion L a year all over world. 3 The catalytic gas phase oxidation of ethanol and other alcohols by such available and environmentally friendly oxidizing agents as molecular oxygen (in air) for the purpose of devising new green technologies for obtaining the corresponding aldehydes, carboxylic acids, and other derivatives is a high priority line of study. Various heterogeneous catalyst have been reported for the oxidation of ethanol in gas phase; Mo0.61V0.31Nb0.08Ox/TiO2,V2O5/TiO2,V-Mo-Te-Nb,Sn & Mo oxide, Au/TiO2,Co and Ni supported on mixed oxides and AuCu/SiO2. This paper describes the synthesis, characterization and use of Au supported cerium oxide for the gas oxidation of aqueous ethanol. 2. Material and Methods: 2.1 Materials: The gold precursor HAuCl4.xH2O was obtained from Finar chemicals, India contained 49.0 ± 0.5% by weight of gold, Ceria Oxide (CeO2) was obtained from Sigma Aldrich, Banglore, India with particle size approximately 25 nm. 2.2 Synthesis of catalyst: Au/CeO2 synthesized by wet impregnation method. 2.3 Catalyst characterization: IR spectra of sample were collected in reflection mode using Zn-Se optics in Bruker Alpha Eco-ATR spectrometer. Catalyst structures were examined by X-ray diffraction (XRD) on a Bruker - D8 discover equipped with a Ni-filtered Cu Kα radiation source (λ = 1.542 Å) of 40 kV and 30 mA. Scanning electron microscopy (SEM) studies were performed using HITACHI VP SEM S-3400N. 2.4 Catalytic testing: Catalytic gas phase reactions were conducted in all heated stainless steel continuous fixed bed flow system using 1gm of Au/CeO2 catalyst and 10 wt % aqueous ethanol solutions as feedstock. The liquid (aq. Ethanol) was mixed with air (21 % O2, 79% N2) prior to enter in the reactor. The mixer was allowed to flow through catalyst bed for 60 min before monitoring reaction products. 1 3. Results and Discussions: 3.1 X-ray Diffraction: - A very small diffraction line at 2Ѳ = 38.34◦, that can be attributed to the (1 1 1) plane of Au was seen in the case of Au/CeO2 (Fig. 1); this is not unusual and indicates that the small Au atoms loading are of small clusters (if not a sharp peak would be present). Expected Au (111) Figure 1: XRD Pattern of Au/CeO2 3.2 Catalytic activity: - The catalytic activities were tested at temperature range from 175 – 275 °C at constant pressure of 10 bars. As shown in fig. 2, ethanol conversion increased up to 20% with increased temperature. The selectivity of acetaldehyde remains 100 % up to 225°C. Then it was decreased to 85 % at 275°C. However, increased selectivity of acetone was observed between 225 to 275°C.This may be due to presence of oxygen of cerium oxide on the surface. 110 100 90 80 70 60 50 40 30 20 10 0 25 20 15 10 5 % Conversion % selectivity No formation of acetic acid and other gases like CO2 were found. 0 150 175 200 225 250 275 300 Temperature°C Figure 2: Ethanol oxidation at different temperature and constant pressure of 10 bars and mole ratio of O2/Ethanol- 1:1. Product selectivities of ( ) acetaldehyde,( ) acetone and (◊) ethanol conversion 4. Conclusion: The Au supported cerium oxide was successfully synthesized and characterized by XRD and FTIR. It shows the good activity for the conversion of aqueous ethanol (10 % wt). Maximum 20 % conversion was achieved at lower mole ratio of O2/Ethanol (1:1) and lower residence time of 300 sec. The formation of acetone taking place between 225 to 275°C where never been mentioned. References:[1] Tembe, S.; Patrick, G.; Scurrell, M., Gold Bull, 42(4), 2009, 321-327 [2] Gorbanev, Y. Y.; Kegnæs, S.; Hanning, C. W.; Hansen, T. W.; Riisager, A., ACS Catal., 2 (4), 2012, 604–612 [3] Takei, T.; Suenaga, J.; Ishida, T.; Haruta, M., Top. Catal., 58 (4-6), 2015 , 295–301 2