Cumene Plant

advertisement

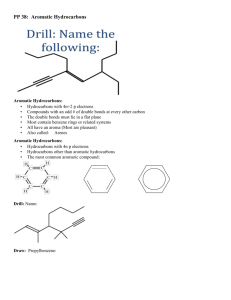

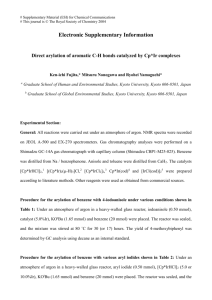

Pennsylvania State University Cumene Plant Final Assignment S. Bina, L. Brethauer, C. Janiszewski, E. Reed, J. Snyder Team 25 0 Executive Summary The goal of this project was to determine the feasibility of a proposed cumene plant to be located on the US Gulf Coast. It will be used to produce cumene from a propylene and benzene feed. The plant consists of a main cumene reactor, a trans-alkylation reactor, and nine distillation towers. A new catalyst is proposed which makes the selectivity for producing cumene higher, but may have higher capital and utility costs. The new catalyst proposed from the R&D department may give the cumene plant a competitive edge compared to other companies in the industry. The feed to the cumene plant consists of a fresh propylene feed and a fresh benzene feed with a recycle stream. The plant produces a capacity of 473 MMlb/yr with a 99.95 wt% purity cumene product. The estimated capital cost to build the plant is $49MM. The yearly utilities of the plant cost $7.7MM. The base case economics result in an After Tax Return of 21.75% and a NPW of %28.7MM. The analysis was based on a standard 3 year sellout period and the prices given by the Marketing Department for propylene at 50c/lb and benzene at 51.85c/lb. It is predicted that there will be a compound yearly increase of 4.2% of cumene until the year of 2020. Based solely on the economic analysis, there is room in the cumene market to become established and grow successfully. It is our recommendation to do not proceed for several reasons unless the following is accomplished. 1. All contracts to sell cumene must be priced with an escalator to the cost of benzene and proplyene. This safeguards against rising raw materials costs. 2. Market surveys of the cumene market reveal no foreseeable downturn. 3. Removed toulene and benzene are purified and sold for profit. 4. A study should be conducted to determine optimal plant capacity. There are two main technical difficulties with regards to building the cumene plant: waste management and the catalyst. The base case does not sell side products that do not go into the fuel drum, such as benzene and toluene. With multiple waste streams leaving the system, it is important to ensure proper disposal of the chemicals. This will require extra attention and costs to the plant. Secondly, there needs to be more research conducted on the catalyst in order to verify that it gives a higher selectivity to cumene compared to other competitors. This is an important technical issue because it is vital to know all of the information of the catalyst and confirm its efficacy before implementing it into multimillion dollar cumene synthesis factory. With high risk sensitivities, the decision to move forward with the construction of the cumene plant becomes more complicated. Although the projected economic and market analysis is in 1 our favor, the highly sensitive facts such as price per pound deems this cumene plant as too risky an investment. 2 Table of Contents I. II. Background Process Description 4 6 BFD PFD Cumene Specification Sheet Material Balance III. Process & Equipment Design IV. Case Studies V. Outside Battery Limit VI. Environmental & Safety Considerations VII. Capital Estimate VIII. Operating Costs IX. Outstanding Issues X. Economic Evaluation XI. Conclusion with Recommendations XII. References XIII. Appendix Equipment Design Calculations Sigma-Aldrich MSDS Plant Specification Sheet 3 9 23 26 28 31 33 36 37 41 44 45 Background The compound cumene belongs in the Industrial Chemical Manufacturing industry. This industry in the United States has brought in total revenue of $275 billion dollars. This was split among the 1,500 companies in the US that are a part of this industry. There is a substantial amount of trade including imports to Canada, China and Germany. The US exports to Mexico, Canada, Belgium, China, and Brazil. Cumene entered the market in 1944 by Hack and Lang when they proved cumene could be oxidized to form a hydrocarbon that decomposes to form phenol and acetone. The demand for cumene increased during World War II in order to help increase the octane rating of America’s aviation fuel program. Cumene is used to create two prominent organic chemicals: phenol and acetone. Phenol is used for Bisphenol A (BPA) which is used to create epoxy resins used in electronic devices including CDs. Diluted phenol is found in disinfectant products including house cleaners and mouthwash. Acetone is a low toxicity chemical, and 75% of the acetone produced is used to formulate other chemicals. Nail polish remover is an everyday product in which acetone is the main component. The production of organic chemicals has increased just over 2 percent according to the February 2015 quarterly industry update, which directly affects the production of cumene. The components reacted and produced in the cumene reactor can be used in a variety of industries. The reaction of benzene and propylene produces primarily cumene, as well as ethyl benzene, and butyl benzene. Ethyl benzene, butyl benzene, and leftover propylene combine to create a fuel source. In order to continue in the development of a cumene plant using new catalyst, profitability must be shown. Profitability will be evaluated through market trends for reactants and products. The market has been steadily growing worldwide, particularly in Asia. The main competitor in the cumene market is Badger, who also reacts benzene and propylene. The reactions take place in the liquid phase in catalyzed fixed bed reactors. The process is flexible because the fresh propylene feed entering the process can be a variety of grades. Even though there are international competitors in the cumene market, there is still a high enough demand to stay in business and retain customers. The demand for cumene is projected to 4 steadily increase at an annual compound growth rate of approximately 4.2% till 2020. With the high projected demand for cumene, a new cumene plant entering the market will not struggle to make money or compete with already established companies. 5 I. Process Description This chemical process uses benzene and propylene to produce cumene at a high purity and high conversion. There are a number of side reactions that take place. Some products of the side reactions can be further reacted to produce cumene, while some are undesirable. It is important to limit the undesired reactions. This is done by removing certain species from the effluent of the main reactor, effluent of the trans-alkylation reactor, and from both fresh feed streams. Below is an illustration of each reaction and side reaction that occurs within the process. Note: This Process description will be based numerically off of the PFD for reference. 6 Trans-Alkylation Reactions The fresh benzene stream (111) is purged of toluene (113), which increases the benzene purity from 95 wt% to 99.8 wt%. This operation requires a distillation column with 30 trays and duty of 1.4 X 107 BTU/hr. The fresh propylene stream (101) is purified by 2 distillation columns. The first and second column removes nearly all ethylene (102) and butene (105) respectively. The total duty from both columns is 5.6 X 106 BTU/hr. These operations are worth the cost because of how it eases downstream operation and reduces the formation of undesired products. Both purified streams are then mixed with the benzene recycle stream. The mixed effluent (121) is separated based on phase. The vapor phase is compressed to 500 psia, and the liquid phase is pumped to 500 psia. The streams are reintroduced and heated with high pressure steam to optimized temperature and pressure for the main reactor. The conditions of the feed to the main reactor are 470 ̊F and 495 psia. The main reactor, at volume 230 ft3, runs at 370 ̊F and pressure drop of 15 psia. The product stream contains 93 wt% cumene. This spec would not be met without the initial separation of undesired reactants. The effluent of the reactor stream is cooled with cold water so that it can be allotted through valve V-201 to reduce pressure from 475 psia to 30 psia. This reduction in pressure increases the relative volatility of the species from the effluent to be separated more readily. Catalyst regeneration in the main reactor is done by feeding steam through stream 202 and out stream 203. Valves V-201, V-204, and V-205 remain open during production while valves V-202 and 203 remain closed until catalyst regeneration is completed. The main reactor product stream is sent to the first of four separators in the third section of the plant design (201). The first separator removes benzene and all lighter species (301) so that the cumene recovered from the reboiler (311) can be purified downstream. The benzene stream is purified further by removing propane, propene, and lighter undesired species by distillation (302). The benzene stream is now pure enough to recycle (314) and feed to the trans-alkylation reactor (315). The heavy stream from the first distillation separator is sent to two separators (311). The first of the two distillation columns produces the high purity cumene product stream (322) by removing heavier species including PIBP’s (323). The second column removes the undesired heavy species, such as terphenyl (325), so that the distillate is a majority of PIPB’s (324). The purified PIPB and benzene stream (the feeds for the trans-reactor), at a 1:6 7 respective ratio, are prepared for trans-alkylation by pumps and a heater, utilizing high pressure steam, to be congruent with the trans-reactor pressure and temperature specs as it moves into the fourth stage of operation. The feed stream into the trans-alkylation reactor (401) is at 338 ̊F and 250 psia. Since the benzene feed to the reactor was very pure, based on components lighter than benzene, the effluent from the trans-reactor (402) can be separated as a fuel product (503) in the fifth stage of operation. It is pressurized and cooled to 50 psia and 110 ̊F to be sold. The bottoms product (502) is recycled and mixed with the bottoms product of the first distillation column of the third operation stage. This recycles the PIPB’s, recovers cumene produced in the trans-reactor, and removes some heavy species downstream. 8 II. Process and Equipment Design Introduction The design of the distillation columns used as the major separation unit operations follows this procedure: equilibrium diagrams of the key species being separated were examined and from these, the optimal pressure for the column was selected. Often this was atmospheric pressure to lower the capital cost of the distillation column. This was selected because cheaper material is able to be used to construct the column due to minimal pressure differentials between the inside and outside of the column. Sizing of the column was performed using graph of the reflux ratio versus the number of theoretical trays. The ‘knee of the curve’ point on the graph was selected as the optimal compromise between the reflux ratio and number of trays. This allows a balance between capital cost and continuous operation cost. The main reactor was designed to have the greatest cumene to propylene conversion ratio in the reactor. To minimize the size of the main reactor, a packed bed reactor was selected. This was accomplished by graphing the cumene to propylene conversion ratio and the benzene to propylene feed ratio, and graphing the cumene to propylene conversion ratio and WHSV at the selected benzene to feed ratio. The conditions of the main reactor determined from the graphs were then used to determine duty of the main reactor heat exchanger. This is further discussed in detail in the main reactor KDV section below. The trans-alkylation reactor size was determined from the flow of the inlet stream to the reactor. Specifications of the packed bed trans-alkylation reactor conditions and catalyst were previously specified. By utilizing the flow of the inlet stream to be reacted and the WHSV ratio of 4, the mass of catalyst required was calculated. From the mass of catalyst required for the reactor, the bulk packing of the catalyst, and the void fraction of the catalyst, the volume of the trans-alkylation reactor was calculated. Main Reactor Design The inlet operating pressure was chosen to be 251 psia as it was the lowest operating pressure that the stream was in liquid phase at the inlet pressure of 300 °F. The determined pressure drop was found to be 20 psi, the largest pressure drop allowed by specification, was also calculated from the Ergun equation. The large pressure drop increases the width of the velocity profile, causing the liquid to have more surface interactions with the catalyst lengthwise. This increased interaction allows for the minimum conversion of 0.96 for proplyene to cumene to be achieved in a smaller reactor volume than that of a reactor with a smaller pressure drop. 9 The reactor benzene to propylene feed ratio and the WHSV ratio was determined from graphs in Figures A and B shown below. Figure A, the graph of the cumene to propylene conversion ratio versus the benzene to propylene feed ratio was plotted. From Figure A, the peak for greatest cumene to propylene conversion ratio was chosen at a benzene to propylene feed ratio of 7. Then, in Figure B, the cumene to propylene conversion ratio was plotted versus the WHSV (mass flow per mass of catalyst) at the chosen benzene to propylene feed ratio with different reactor temperatures. From the graph of the multiple curves (each representing a different reactor operating temperature), the greatest conversion that was less than 1 (because of interpolation errors in the fitted data) was selected from the curve at the temperature at which the conversion was the greatest. Finally, the WHSV was then selected from that point on the curve. 1 1 Cumene/Prop Convesion Greatest Cumene/Propylene Conversion Cumene/Propylene Conversion vs. Bz/C3 Ratio in Main Reactor 0.995 0.99 0.985 0.98 0.975 Cumene/Prop Conv. vs. WHSV @ Bz/Prop Ratio=7 0.8 0.6 100 0.4 200 300 0.2 0.97 400 0 0.965 0 2 4 6 Bz/C3 Ratio 8 10 Figure A. Comparison of cumene to propylene conversion ratio and benzene to propylene feed ratio 1 2 3 4 5 6 7 8 10 WHSV Figure B. Greatest Cumene/Propylene conversion ratio (less than 1) = 0.9997 at 400°F Separation Process Design In order to better understand the Cumene plant, the entire system of separators is broken down into 3 sections. The first system of separators includes three distillation columns that are set-up before the main reactor. The second system of separators occurs directly after the first reactor. The third separating process system is necessary to reach a cumene specification of 0.9995 wt%. A summary table is provided for each separator that lists key parameters such as the temperature, pressure, mole fractions of the streams along with optimization details about the distillation columns. 10 9 1st Separation Process System Separator T-111: Toluene/Benzene Purpose The purpose of this first separator is to separate the toluene from benzene. By having a high mole fraction of toluene separated out from the entire process, the reaction between toluene and propylene resulting in o-cymene occurs at a minimal amount. This is very beneficial for the plant because there are fewer impurities that prevent high conversions of cumene and other products. By minimizing this reaction using the first separator, the sizing of the reactors and other separators will be smaller. Operating Conditions The inlet stream is at atmospheric pressure and a temperature of 110°F. The exiting benzene stream is at 162.6°F and 11.60 psia while the toluene stream leaving the tower is at 230.5°F and at atmospheric pressure. The condenser is operating at 11.60 psia. The number of stages for benzene/toluene separation process is 30 which results in a reflux ratio of 0.855 as seen in Figure 1. The feed tray in which the reactants enter the separator was found using empirical calculations in HYSYS. The reactants enter at the 11th tray, which gives a new reflux ratio 0.833. According to figure 2, the stream of toluene and benzene is entering at atmospheric pressure. This is a relatively difficult separation to make and therefore requires more stages to make the separation possible. 70 T-111 60 # of stages 50 40 30 20 10 0 0 1 2 3 4 RR Figure 1. Reflux ratio versus theoretical number of trays Figure 2. The X-Y diagram for benzene at 14.7 psia 11 Summary Chart Separator T-101: Ethylene/ Propane, Propene, Butene Purpose The purpose of this separator is to remove the butene from ethylene, propane, and propene. The propene is desired for downstream operations. The propane and ethylene will eventually go into a fuel drum storage container for profit. The propene is then used to make cumene. By separating out butene, butyl benzene will not be made in significant quantity and therefore less heavier products will be produced. Again, this makes the reactor sizing smaller, and fewer impurities results in a higher conversion of desired products. Operating Conditions The inlet temperature to the separator is -22.09°F and 30.0 psia. The top stream is leaving at 40.35°F at 20 psia while the bottoms are 22 T-101 # of stages 20 18 16 14 12 10 0.15 0.2 0.25 0.3 0.35 0.4 0.45 RR Figure 4. The X-Y diagram for butane at 29.01 psia Figure 3. Reflux ratio versus theoretical trays 12 leaving at 55.9°F and 30.0 psia. The number of stages for the distillation column is 17 from figure 3 with a reflux ratio of 0.216. Through empirical calculations, the optimal tray to have the feed entering is the 7th tray. This gives a new reflux ratio of 0.216. Summary Chart Separator T-102: Propene, Propane/1-Butene Purpose The purpose of this reactor is to separate the ethylene which will be stored in the fuel drum. The propane and propene stream will be recycled back into the system because propene reacts to create cumene. It is important to keep reactants that make cumene, such as propylene in high concentration in the system in order to maximize the conversion of cumene. Operating Conditions The inlet temperature and pressure are at -23.19°F and 30.00 psia. The ethylene stream leaving the top of the distillation column has a temperature and pressure of -145.5°F and 20.00 psia. The propane and propene stream leaving the bottom leaves at -22.09°F and 30 psia. The number of stages for this separator is 15 with a reflux ratio of 63.1 as shown in Figure 5. The feed should enter at 7th tray, determined by empirical calculations. According to Figure 6, this is an easy separation because of the big difference between ethylene and the propane/propene mixture. 13 T-102 # of stages 20 15 10 5 0 55 65 75 85 RR Figure 6. The X-Y diagram for propene at 20 psia Figure 5. Reflux ratio versus theoretical trays Summary Chart 2nd Process Separator System Separator T-301: Benzene, Propene/Cumene, PIPB Purpose: After leaving the main cumene reactor, the reactor effluent is mixed with the trans-alkylation reactor effluent, creating stream 1 from this separation system. This stream contains large amounts of cumene. The first separator is used to separate a benzene rich light stream with propene impurities from a heavy stream of cumene with PIPB impurities. 14 Operating Conditions The inlet temperature and pressure of this distillation are at 222.1 and 30 psia. The reactor effluent exists at a higher pressure (200 psia), which causes this separation to be more difficult and take more energy. The XY equilibriumplot for this separation at 200 psia as well as the XY equilibrium plot at 30 psia are shown below. Figure 8. Benzene/Cumene Separation at 210 psia Figure 7. Benzene/Cumene Separation at 30 psia Figure 7 illustrates that this separation is easier at atmospheric conditions. Because of this, the reactor effluent is depressurized before this separation. The main specification for this separation is the cumene recovery, as the main economic benefit of this process is cumene sales, and the benzene recycle cannot have more than 1000 ppm cumene in it. Due to this, this distillation column was set to have a cumene recovery of .999. To save energy, the reflux ratio was set at 2. With a reflux ratio of 2, this separation could be run with 25 stages, with the inlet flow fed to the 13th stage. 15 Summary Chart Separator T-311: Benzene/Propane and Propene Purpose After separating the cumene from the benzene in separator 1, the benzene is still not pure enough to be recycled to the main reactor and the trans-alkyation reactor. The largest of the impurities in this stream consist of propene and propane. This separator exists in order to remove the propane and propene from the benzene stream. Operating Conditions The feed to this distillation consists mainly of benzene at 98.72 wt% purity and 14.7 psia. Without running this separation under a vacuum, 14.7 psia is the lowest pressure at which this separation can occur, and the separation is easier at lower pressures, thus the pressure will not be changed before this separation occurs. For this separation, the main variables that are important are the purity of benzene as well as the amount of benzene kept in the system. This separation is set to make the benzene purity at 99.7 wt%, with hexane making up the majority of the impurities (the hexane is approximately 2900 ppm, which is below specifications for reactor inlets). The other specification set for this distillation is a benzene recovery of 99%, so that little benzene is lost with the propene and propane. 16 The knee of the curve method was used to determine that this separation should be run with 8 stages and a reflux ratio of 0.725. The graph of reflux ratio vs. number of stages is shown below in Figure 11. T-311 30 # of Stages 25 20 15 10 5 0 0 2 4 6 8 10 Reflux Ratio Figure 10. Stages vs. Reflux Ratio for Separator 2 This graph shows that the minimum stages necessary for this separation is approximately 3, while the reflux ratio hits a minimum at about 0.624. Using the knee of the curve method, it was determined that 8 stages were ideal for this separation, as adding more stages would not heavily affect the reflux ratio. Summary Chart Temperature (inlet, top, bottom) °F Pressure (inlet, top, bottom) psia 138.5 ; 45.52 ; 194.9 14.7, 14.7, 20 Feed tray pressure psia 18.36 Feed tray temperature °F Feed composition (mole fraction) Benzene Propene 146.4 0.9872 0.0068 Benzene (bottom) mole fraction 0.997 Benzene (top) mole fraction 0.0916 Number of stages; feed tray 8;3 Reflux ratio 0.725 17 Separator T-331: Cumene/PIPB Purpose After the cumene is separated from benzene, it must be purified to meet the specifications for the consumer (99.95 wt% pure). Similarly, the PIPB must be separated in order to send to the trans-alkylation reactor. Operating Conditions: At atmospheric pressure, this separation is much easier than at any higher pressure, so the inlet feed is left at its previous value of 20 psia as this is fairly close to atmospheric, and would keep capital costs down for a pressure drop. The temperature as this feed enters the tower is in the middle of the range for the tower, and thus little energy is needed to change the temperature when it is added. The specifications for this distillation column were created in order to obtain the necessary purity of cumene with a minimal loss of cumene. In order to achieve this, the top of the column was set to have a cumene purity of 99.95% by weight. In order to minimize cumene loss, The other specification set for this separation was a cumene recovery of 99.9%. This separation is run using 20 stages and a reflux ratio of 1.06. Below is a graph of the number of stages in the separation vs. the reflux ratio. 40 T-331 35 # of stages 30 25 20 15 10 5 0 0 0.5 1 1.5 2 2.5 3 Reflux Ratio Figure 11. Reflux ratio versus theoretical trays This graph shows that the minimum number of stages possible for this separation is about 14, while the minimum reflux is about 0.6. Using 20 stages and a reflux ratio of 1.06 minimizes the run cost as much as can be done without adding too much capital. 18 Summary Chart Temperature (inlet, top, bottom) °F Pressure (inlet, top, bottom) psia 335.5 ; 308.2 ; 458 20 ; 14.7 ; 20 Feed tray pressure psia 19.84 Feed tray temperature °F Feed composition (mole fraction) Cumene PIPB 333.2 0.9216 0.555 Cumene (top) mass fraction 0.998 PIPB (bottom) mole fraction 0.7106 Number of stages; feed tray 20 ; 10 Reflux ratio 1.06 Separator T-332: Heavies/PIPBs Purpose The purpose of this separator is to remove the heavies from the PIPB stream. This is an important process because it prevents the heavies from entering the trans-alkylation reactor, which would decrease the amount of conversion to cumene. Heavies also build up in the reactors, so this will help to prevent some extra maintenance. Operating Conditions The inlet pressure to this separation is left at below atmospheric pressure in order to make the separation utilize less energy. The temperature of this feed is inside the temperature range for the distillation column, so it does not take much energy to heat or cool the feed after it has entered the distillation column. The flowrate entering the distillation column is 372 lbs/hr, which is relatively small compared to other streams in the system. 19 30 T-332 # of stages 25 20 15 10 5 0 0 10 20 30 40 50 Reflux Ratio Figure 12. Reflux ratio versus theoretical trays Summary Chart Temperature (inlet, top, bottom) °F Pressure (inlet, top, bottom) psia 409.4 ; 164.3 ; 308.3 20.0 ; 7.0 ; 9.0 Feed tray pressure psia 7.8 Feed tray temperature °F Feed composition (mole fraction) Heavies PIPBS 0.519 0.7648 PIPBs (top) mole fraction 0.8144 Heavies (bottom) mole fraction 0.5714 Number of stages; feed tray 15 ; 7 Reflux ratio 411.9 10 3rd Separation Process System Separator T-501: Cumene, PIPBs/Benzene Purpose The purpose of the separator is to recycle the bottom cumene and PIPB stream back into the system. The top stream is mostly benzene, which will be sent to the fuel drum. This separation is important because by recycling pure amount of PIPBs and cumene back into the system there is a more pure final cumene product. 20 Summary Chart Temperature (inlet, top, bottom) °F 195.9 ; 176.1 ; 360.3 Pressure (inlet, top, bottom) psia 20 ; 14.7 ; 20 Feed tray pressure psia 18.79 Feed tray temperature °F Feed composition (mole fraction) Benzene Cumene 191.5 0.9828 0.0086 Benzene/hexane (top) mole fraction 0.9999 Cumene (bottom) mole fraction 0.6824 Number of stages; feed tray 20 ; 10 Reflux ratio 1.07 Separator T-601: Cumene Purification Purpose The purpose of this final separator is to reach the cumene specification in order to sell it to the customers. The separation involves benzene and cumene. The benzene will go to waste because it does not meet the specification to sell it. Operating Conditions This is the last separation in the system and it is important to keep the tower optimized at the point in which the final cumene product leaving meets the specification of 99.95 wt%. There is a mass flow rate of 57201 lbs/hr flowing into the separator. The mass flowrate of cumene leaving the bottoms is 56298 lbs/hr. The mass percent of cumene entering the reactor is already relatively high, so only a small impurity of benzene needs to be removed from the system in order to reach specification. 21 # of stages 15 14 13 12 11 10 9 8 7 6 T-601 15 20 25 Reflux Ratio Summary Chart 22 30 35 III. Case Studies Design Case I In the final design of the cumene plant, there are three separators before the reactants enter the main cumene reactor. The products separated or being purged out of the system for fuel storage includes ethylene, butene, and propane in the fresh propene feed. The separation of ethylene and butene out of the system in order to purify the propene stream requires two separators. After analyzing the boiling points of each reactant, it was determined that the two separators can be combined into one separator with a total of three streams leaving. The top product in the new distillation tower would be ethylene with a boiling point of -154°C. The middle stream leaving the separator would be propene with a boiling point of 53°C. The purified propene stream stays in the system by going to the cumene reactor to produce cumene. Finally, the bottom stream leaving the distillation tower would be butene with a boiling point of 21°C. None of the reactants have a similar boiling point, which makes the separation relatively easy. Therefore, the new distillation tower does not need to be too complex with the amount of trays in order to make the separations possible. Butene and ethylene are both sent to the fuel drum for storage and to sell as product. This design would overall benefit the cumene plant in a cost effective way. By turning the job of two towers into a single column reduces the amount of equipment needed for the plant. This makes a difference in maintenance of the entire system, particularly during shut down for maintenance. The fresh feed stream flow rate is 21760 lbs/hr, therefore the new tower will need to be sized to fit such a high flowrate. In conclusion, the amount of butylene in the feed is minimal compared to the amounts of propylene and ethylene. Separating the propylene and ethylene to high purity is possible, but the final bottom butylene stream will be mostly propene not providing the desired separation. This conclusion is supported by observation of the flow rates from each of the three streams emulated in HYSYS. The flow rate of ethylene out is 163lb/hr with an ethylene purity of 99.95 wt%. The flow of propylene out is 21 lb/hr with a purity of 93.94 wt% propylene. The bottoms flow of butylene out is 21580 lb/hr with a propylene purity of 93.25 wt% with most of the butylene exiting with this stream at a purity of 0.29 wt% butylene. This separation would be useful if the propylene fresh feed was of lower purity with greater ratios of butylene and/or ethylene. It is possible that a less costly and lower purity propylene feed could be used to lower the overall cost to produce cumene by using this separation. Comparing the utility cost of the two towers with the one tower, the condenser will use over half the energy (6.94E6Btu/hr total for both condensers vs. 3.2E6Btu/hr for the single condenser) and the reboiler will use over 23 three times less energy than both reboilers (5.456E6Btu/hr for both reboilers vs. 1.7E6Btu/hr for the single reboiler). Design Case II The distillate leaving T-311 is a mix of propene and propane. As of now in the main design, the stream will be sent to the fuel drum. Propene is used throughout the cumene plant in order to make cumene, so it is not ideal to send excess to the fuel drum. In order to utilize a greater percentage of the incoming propene, rather than allowing it to escape the process with the propane, a new distillation column could be added to the system after propane and propene are separated from benzene. This new distillation would keep a larger amount of propene in the process, granting a greater yield of cumene. Also, the propane leaving the system would then be more pure, and thus could be sold as a side product. The total mass distillation flowrate leaving the tower is 1716 lbs/hr. The mass fractions of propane and propene are 0.8489 and 0.1457. This is a small amount of propene leaving the system, although the propane would be sold for a small profit. The added distillation column would add more capital cost for the system. Also, the separation of propene from propane is relatively difficult, and would likely take a lot of energy in order to keep propane impurities from accumulating through the system. Instead of storing the propane as fuel, the propane could be purified to sell. This requires a specification of 99.5 wt%. This would require a lot of adjustment in the distillation tower in order to accommodate a high specification. Finally, it should be noted that the majority of the propene is used during a single pass, which would make the amount recycled very small. This separation was modeled using HYSYS as an extension of our base case. In this case, a separator was added to the vapor stream coming from distillation tower T-302 in order to separate propene from propane. With a 95 wt.% amount of propene (the purity that was initially fed to the system) in the distillate, the maximum amount of propene that can be 24 obtained was 6.25 lbmol/hr, which is slightly larger than 1% of the amount of propene fed to the system. In order to obtain this, a minimum of 47 stages are necessary (using a reflux ratio of over 10,000). A more realistic number of stages for this separation would be using 60 stages, which gives a reflux ratio of 53. For such a small amount of propene that would be salvaged, an extra 60 stage distillation tower would be far too expensive in just capital cost. There is not enough benefit from this separation to warrant the construction and maintenance of this tower, especially as it would have more stages than any other tower in this plant. That is without even mentioning the energy cost of running the tower. Quantitatively, the tower itself would cost approximately 486000 USD in capital costs alone. This tower would also need to cool the distillate to -421.1 F, using about 900,000 BTU/hr. This refrigeration cost would dwarf the cost of the propene that would be saved. 25 IV. Outside Battery Limit The Out of Battery Limit, or OBL, comprises all equipment and costs not associated with process equipment. While not directly affecting the process, the OBL is necessary for the site to start up and operate continually. Site development deals with the costs associated with clearing the desired plant location, excavating the desired site location, ensuring the site has proper runoff, and beautifying the site once construction is complete. Excavation, while not a technically difficult task, requires large amounts of man power and equipment. Landscaping and beautifying of the site after construction is also important as it keep the plant appearance up and also helps prevent runoff during storms. Site development did not need to be scaled up as it was not based on any process flows and the base price was evaluated in 2014. OBL utilities encompass lighting for buildings, cold water pumps, low pressure steam for steam tracing, water utilities for various buildings and power for out of process pumps. These utilities essentially keep the building inhabitable for workers and ensure that all necessary utilities, such 26 as cold water, to reach the heat exchangers they run through. Utilities had to be scaled up for two reasons. The base price was evaluated in 2012, so the price had to be scaled up to present day prices. This was done by multiplying the base price by 1.03N, where N= the number of years between the current year and the base price year. To scale up for the size of the process, the utilities price was multiplied by the ratio of the process feed to the utilities base feed. Raw material/product storage was necessary to store materials away from the plant to ensure safety. This protects the materials against plant explosion and the plant against any chemical spills. The storage tanks will be placed outside on cement pad sites outside of the possible blast radius of the plant. Pumps will be required to pump the raw materials into the plant. The cost of the pumps and their utilities are included in the OBL utilities costs. Storage for product will also be located there, allowing random pickup of product without disturbance of the process. Raw material/product storage costs had to be scaled up. The base price was evaluated in 2010, so the price had to be scaled up to present day prices. This was done by multiplying the base price by 1.03N, where N= the number of years between the current year and the base price year. To scale up for the size of the process, the storage price was multiplied by the ratio of the process feed to the assumed process feed. Environmental OBL costs include costs to ensure that we meet required EPA specifications and are doing no harm to the surrounding community. This includes waste water treatment if necessary, air quality control, spill control, and hazard prevention and preparedness. Environmental OBL did not need to be scaled up as it does not have direct ties to the process or its capacity. 27 V. Environmental & Safety Considerations General safety guidelines These guidelines are put in place to eliminate hazards and catastrophes that can occur in this chemical plant. Proper precautions must be taken to ensure a safe environment and working conditions. Guidelines for safety are as listed: Guidelines Identify a hazard Assess the hazard Avoid hazard Reduce hazard source severity Reduce the likelihood of hazard With these steps in place we can determine when to use passive, active, or procedural safeguards to prevent said hazard. Passive safeguards are the easiest to implement and take little to no maintenance. A simple drain or dyke qualifies as a passive safeguard. Active safeguards are put in place to measure a system and report if it detects a hazard. A safeguard like a temperature probe or pressure gauge require periodic evaluation. Procedural safeguards outline how a certain hazard is dealt with step by step. Procedural safeguards include systematic disposal of dangerous material as well as what to do after the plant undergoes emergency shutdown. The equipment and process was analyzed and these three safeguards were implemented as we see fit. Process Safety There are a few safety measures that will be implemented to avoid hazards. The following list encompasses the general safety of the process: Process Safety: Insulation of pipes that have high temperatures Small batch volumes to reduce the amount of flammable liquid in one place 28 Segregation of the reactors from each other and other equipment to reduce up/downstream damage Detection systems for construction and human error: eg: leaks from bad welds or operator mistakes Equipment Safety Reactors Both reactors experience an exothermic catalytic reaction. Identified hazards include thermal runaway, spilling, and the abundance hot surfaces. To guard against thermal runaway it is important to have control systems in place that will control downstream processes to limit reactions in the reactor. If these systems fail to recognize a thermal runaway in time we must quench the reaction by dumping the reactor contents into a knockout drum. Quenching will be carried out initially by water (high heat capacity) as an active safeguard. Cascade quenching may be necessary to completely stop the thermal runaway. Sulfuric acid will be next to quench followed by another quench of either water or acid, depending on the effectiveness of the two previous quenches. Cascade quenching is and procedural safe guard because the third quench is determined by the operator according to the effectiveness of the two previous quenches. Fire safety is very important to assess and can reduce plant damage substantially. To prevent a fire caused by the exothermic reactions we plan to implement a foam sprinkler system. Foam can suppress the fire by separating the fuel from the air. Surrounding systems will be coated so that the fire cannot spread. Spills arise from leaks and leaks will continue to secrete chemicals until they are sealed. Leaked chemicals will be drawn down a drain by ditches and dykes. The drain will collect the hazardous material for proper disposal. Distillation We have 9 distillation columns that run at relatively low pressures. Buying columns with lower maximum pressure ratings is economical. Though some margin for safety is considered when buying a column, steady state operation is commonly the condition considered. It is important to note that flow in the system is fast and at high volume. Therefore, integration of pressure controls to monitor the internal environment of the columns is essential. Fluid backup can cause a pressure increase that the column is not rated for. Larger diameter piping downstream can be used to reduce the likelihood of hazards like this. Some columns run 29 at very high temperatures which may also induce over pressurization. External fire and hot ambient conditions are two examples that will increase the pressure within a column. In extreme measures, crash cooling of the column will be used to eliminate the hazard of overheating. To immediately alleviate the pressure in a column, burst disks are used when the column is under relative extreme pressure. The effluent from the burst disks need to be assessed based on column environment. A flare will be utilized on specific columns where the flow rate is low. If the flow rate is high and the leak is waste it will go to a knockout drum. The drum will be cooled, sealed, and disposed of according to safety procedure. Any leak with fluid that is desired in downstream operation will be sent to do so, after being made conditionally congruent with the mixing point. To reduce the corrosion within the column we may decide to use some type of cathodic protection. This precaution may not be pertinent. Corrosion will be monitored so that we can make an economic decision sometime later. Pumps/Compressors & Heat Exchangers Simple operations such as pumps and exchangers are commonly replaced if they fail. When a pressure system fails the stream is diverted to another pressure system to keep operations in motion. This will avoid any hazards caused by the failed pump. To guard against hazard, pumps with an adequate safety margin are to be used. Etc. Concrete floors guard against ground water contamination. No process uses water so little waste water treatment is needed. For specific information on each component in the system, please refer to the Appendix for a full MSDS on each chemical. 30 VII. Capital Estimate The capital estimate was developed through HYSYS Economic Analysis Software. All equipment was evaluated based on sizing determined from the methods discussed in the Equipment Design section. All equipment was assumed to be made out of carbon steel, the cheapest material. This assumption was safe as no equipment had large enough pressures or temperatures that carbon steel could not handle the stress of. All process equipment, including heat exchangers, pumps, compressors, distillation towers, and reactors, was considered inside battery limit (IBL). HYSYS software was used to only estimate IBL equipment. All IBL equipment costs were assumed to be present day, eliminating the need for escalation. Engineering and installation costs for all IBL equipment were calculated as well and are included in the summary. Outside Battery Limit (OBL) equipment base prices were given. The cost of these goods was scaled up to meet the requirements of the plant design. Scale was performed by first scaling up the given prices to the base year. The base price was multipled by 1.03N, where N= the number of years between the current year and the base price year. To scale up for the size of the process, the OBL price was multiplied by the ratio of the process feed to the OBL base feed. 31 The most expensive piece of equipment is the compressor required to compress propane/propene vapor so that it can be safely stored and sent to a fuel drum. While expensive, at $953,000, the compressor is necessary for safety regulations. Money can also be made from the fuel drum, so the capital cost of the compressor is offset by the profits brought in from the fuel drum. Contributing the large cost is the large size of the compressor, approximately 1500 ft3. Two compressors in series could help reduce cost as the load for each would be significantly less. All other equipment was appropriately sized and reasonably priced. 32 VIII. Operating Costs Operating Costs: The most important costs are raw material costs, as these have the ability to change drastically based on the market. Benzene and propene are the largest components of raw materials costs. Benzene prices are directly correlated to oil prices as it is recovered from cracking crude oil. While benzene prices have fluctuated over the past decade, there has been a steady increase, with prices topping $4.82/gal in 2014, a $2.00 jump since the last reported price of $2.82/gal in 2010. This large jump in price can be attributed to high crude oil prices in the past two years as well as the high demand for benzene as the world continues to consume plastics rapidly. 70 Benzene 60 50 ¢/lb 40 30 20 10 0 1990 2000 Year 2010 Figure 14. Pricing of Benzene from 1990 to 2015 Like benzene, propylene prices have been steadily increasing for the past decade. Propene is the other major component of the raw materials costs. Raw material costs are drastically important because if the price of raw materials have the ability to change easily. If the prices of benzene and propene were to spike, the plant may have to increase the sale price of cumene to remain profitable. This could drive business elsewhere and thus profits for the plant would plunge even lower. 33 80 Propylene ¢/lb 60 40 20 0 1990 1995 2000 2005 2010 2015 Year Figure 15. Prices of propylene from 1990 to 2015 Operating costs for energy will remain somewhat constant as the energy requirements for equipment will not change drastically. Energy costs could affect the profitability of the plant if the drastically increase through the change in oil prices. However, energy prices have remained fairly stagnant in recent years due to an overproduction of oil, new discovery of natural gas in America, and renewable energy sources continuing to rise in popularity and availability. Total energy operating costs were $12.6 million per year. Utility costs for the process were as follows: 34 Utilities costs affect the process much less than raw materials and utilities costs. They are necessary to the process and cannot be waived. Pending a drought, water prices will remain constant with inflation. Catalyst costs are dictated from the manufacturer and will remain fairly constant in order for the company to maintain business. Catalyst also only needs to be bought every few years, allowing the cost to actually decrease per year due to inflation. Utilities costs will also consistently remain low due to the ability to sell used steam. This drastically reduces the cost by almost $5 million in current estimates. Out of all operating costs, utilities costs represent the smallest fraction. 35 IX. Outstanding Issues Disposal of Waste Streams The cumene plant does not sell any effluents leaving the separators besides the cumene. In order to sell the effluent streams, the purity must be 99.5 wt %. This results in multiple waste streams of somewhat high purities of chemicals. This is an issue because there are many policies in place to ensure the safe disposal of chemicals. There is the possibility to have even hazardous waste streams reused or recycled. As stated by Congress, the objectives of the Resource Conservation and Recovery Act (RCRA) are "to promote the protection of health and the environment and to conserve valuable material and energy resources." With these goals in mind, EPA developed the hazardous waste recycling regulations to promote the reuse and reclamation of useful materials in a manner that is safe and protective of human health and the environment. The disposal of chemical waste is not only a safety issue, but an economic one as well considering outsourced waste management companies are needed to properly dispose of the chemicals. The following chemicals are found in the waste streams leaving the cumene plant. Toluene & Benzene Toluene and Benzene are both an odorless liquid at room temperature. They are highly flammable as a liquid and vapor. According to Sigma Aldrich, burning it in a chemical incinerator equipped with an afterburner and scrubber is the best way to dispose of the waste. It is necessary to take extra precaution during this process because the chemical is highly flammable. Contacting a licensed professional waste disposal service to dispose of this material is recommended for both chemicals. Toluene Benzene 36 X. Economic Evaluation Assumptions In order to perform an economic evaluation of this process, various assumptions needed to be made. First of all, the price of raw materials and products was assumed to hold firm through the next fifteen years of operation. Specifically, the price for each material was set to be the average price from the last five years. This made benzene $0.519/lb, propene $0.50/lb, toluene $0.212/lb, propane $0.297/lb, ethylene $0.503/lb, and cumene $0.628/lb. Other assumptions for economic data are as follows: Capacity On-Stream Time Project Life Market Build Capital Spending Depreciation Escalation Discount Rate Income Tax rate Working Capital SG&A 473 MMlb/year 8400 hours/year 15 years from startup 40% / 75% / 100% 15% / 35% / 50% MACRS (20%, 32%, 19.2%, 11.5%, 11.5%, 5.8%) 2.7% per year 12% 35% 10% of Revenues 1% of Sales This plant requres 4 separate shifts with 6 operators in each. The operators will have a salary of $70,000/man-yr, and any overhead will be set using 150% of the labor cost. Repair and maintenance is set at 1.5% of the capital, property taxes are 2.5% of the capital, and Insurance costs .5% of the capital. Base Case The following summary sheet shows the various costs and returns of the base case for this system: 37 Working with the assumptions of this base case, this plant would have a net present value of 28.7 million dollars, giving a rate of return (after taxes) of 21.75%, well above the minimum of 15%. The main cost of this process as shown is the cost of raw materials, costing $0.5661 per pound of cumene produced. Compared to this, the cost of utilities, fixed costs, and the price of sold byproducts (0.0164, 0.0147, and 0.0105 $/lb cumene respectively) are very small. 38 Economic Sensitivities Changes in Capital The capital estimate was developed using ASPEN Icarus, but there is the potential that the price could be quite different from what was predicted based on contractor costs, market changes, and various other unforeseeable issues. For the base case, the capital cost of this process is $49 million, giving an ATROR of 21.75%. In order to maintain the minimum ATROR allowed (15%), the maximum amount of money that could be spent on capital (keeping all other factors the same) would be $72 million, which would constitute a 46.9% change. It is highly unlikely that the capital cost would rise higher than this amount. Changes in Reactant Cost Historically, the prices of both benzene and propene have been lower by over 10 cents/lb, however, these prices have risen dramatically in the last few years (likely due to increases in oil prices). In order to maintain an ATROR of 15%, the price of Benzene may rise by 1.8 cents/lb, or 3.5%. If the benzene price stays the same, the price of propene may rise by 3.3 cents/lb, or 6.6%. With the rising prices of benzene and propene, it is quite possible that these prices may be exceeded at least one time during the 15 year project life. However, the price of cumene has been rising in a similar pattern to propene and benzene, and thus these rising prices will likely be mitigated by the rise in cumene prices. Changes in Cumene Cost As stated previously, the prices of cumene have been rising in recent years, however, it is possible that cumene prices could dip in the future for various reasons. Keeping all values as stated in the base case, the cumene cost may drop by approximately 1.3 cent/lb, or 2% and keep the ATROR above 15%. A drop in cumene cost, however, is unlikely due to current market trends and current changes in crude oil prices. Historical Pricing Historically, the prices of cumene, propene, and benzene have been much lower than the last five years. While all of these prices are fairly well correlated, the lower these prices are, the less negligible the capital, utility, and plant costs become. Below is a table of the ATROR and NPW of the plant using average cumene, propene, and benzene costs from various 5 year periods in recent history. 39 This table shows that, in recent history, this process would not be viable. The recent upsurge in prices of benzene, propene, and cumene are what make this process viable. Should prices hold to the amounts they have had since about 2006, this would be not be viable. The recent upsurge in prices of benzene, propene, and cumene are what make this process viable. Changes in Sellout Rate Due to potential changes in market demand, it is possible that the sellout of this plant’s capacity could happen faster or slower than predicted. Given that all other factors hold firm (capital cost, materials cost, etc), if the plant capacity takes 6 years to sell out instead of 3 years in the base case following a scale up of 20%/35%/50%/75%/80%/100%, the ATROR falls to 16.76%. This allows for the plant capacity to take up to double the expected amount of time to sell out. Conversely, if the capacity is sold faster than expected (a rate of 50%/100%) selling out by the second year, the ATROR may rise as high as 23.21%. 40 XI. Conclusion with Recommendations Based on this study, it is clear that the cumene business is a growing market, yet profit margins are currently very tight. The market for cuemene is expected to grow at an annual compound growth rate of 4.2% until 2020, allowing room for new companies to enter the market without major impact from competitors. However, small changes in benzene and propene costs, both directly correlated to fuel costs, make the profit margins narrow. Technologically, the plant has no foreseeable issues. All distillation columns run at low pressures, making them cheap in capital costs and operating costs while making the process safe. Some further work for downstream tower control systems is needed, as controls based on product purity flow rate would increase quality control. Capital costs to build the plant are approximately $49 million and operating costs are approximately $12 million/year. The current PW is $28.7 million after 19 years. The following table summarizes the economic analysis: 41 The project appears to be marginal at best, as profit margins are highly sensitive. The Base Case calls for an ATROR of 19.9%, comfortably above the required 15% ATROR. However, with only a 3.5% increase in benzene prices or a 6.6% increase in propene prices, the ATROR falls to 15%. These costs are directly tied to oil prices, and while oil prices have been on the steady decline in the past 12 months, they are highly unpredictable. If current trends in the oil market stabilize over the next two years, the recommendation could change from not build to build. A 2.05% decline in cumene prices also returns the ATROR to 15%. While the cumene market and its demand are projected to rise steadily over the next 20 years, further economic studies on the market to ensure no foreseeable market decline would be necessary in order to move forward. A few things could be done to improve these economics. Capital costs can rise 47% before the ATROR falls to 15%, so a scale up of the plant could be done to increase cumene production and thus widen sensitivities. 42 Competition from other plants does not seem to pose a threat. The market for cuemene, and specifically its derivates phenol and acetone have large, varied markets. Phenol and acetone are used in applications from household products to industrial scale chemicals, safeguarding their market should one sector no longer be applicable. Based solely on the tight economic margins, it is recommended that we do not build unless the following can be accomplished: 1. All contracts to sell cumene must be priced with an escalator to the cost of benzene and proplyene. This safeguards against rising raw materials costs. 2. Market surveys of the cumene market reveal no foreseeable downturn. 3. Removed toulene and benzene are purified and sold for profit. 4. A study should be conducted to determine optimal plant capacity. 43 XII. References "Sigma-Aldrich." Sigma-Aldrich. Web. 31 Jan. 2015. <http://www.sigmaaldrich.com/unitedstates.html>. " Cumene :: Badger." Cumene :: Badger. Web. 31 Jan. 2015. <http://www.badgerlicensing.com/TechServices_PC_Cumene.html>. "Energy and Cost Calculator for Heating Water." Water Treatment Solutions. Lenntech, 7 Jan. 2015. Web. 15 Feb. 2015. "The Best Heat Transfer Fluids for Liquid Cooling." Lytron. Lytron Industries, 18 May 2012. Web. 16 Feb. 2015. Jakobsen, Hugo A. "Packed Bed Reactors." Chemical Reactor Modeling (2008): 953-84. Springer Link. Web. 16 Feb. 2015. Robert Nedwick, “Chemical Engineering 470 Blue Book” 2015. 44 Appendix Equipment Design Calculations Sigma-Aldrich MSDS Plant Specification Sheet 45