Cesium Ion Exchange

advertisement

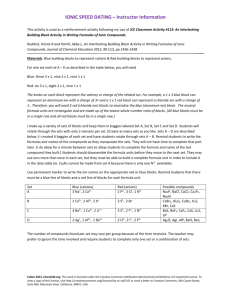

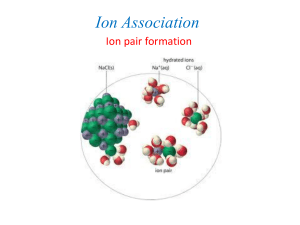

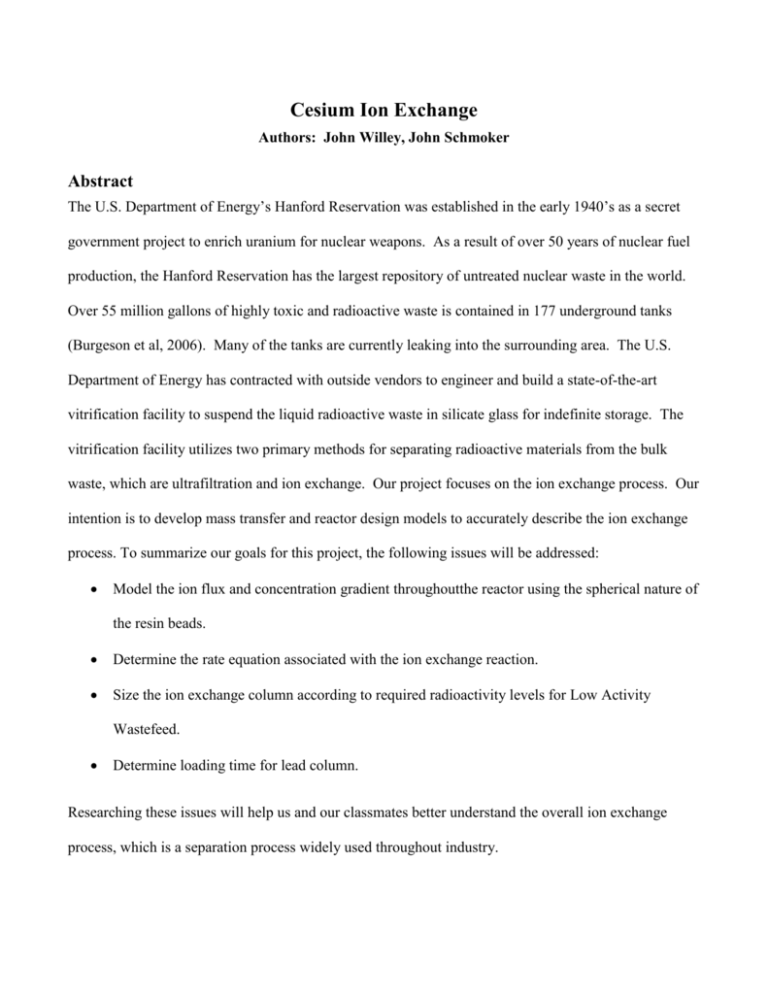

Cesium Ion Exchange Authors: John Willey, John Schmoker Abstract The U.S. Department of Energy’s Hanford Reservation was established in the early 1940’s as a secret government project to enrich uranium for nuclear weapons. As a result of over 50 years of nuclear fuel production, the Hanford Reservation has the largest repository of untreated nuclear waste in the world. Over 55 million gallons of highly toxic and radioactive waste is contained in 177 underground tanks (Burgeson et al, 2006). Many of the tanks are currently leaking into the surrounding area. The U.S. Department of Energy has contracted with outside vendors to engineer and build a state-of-the-art vitrification facility to suspend the liquid radioactive waste in silicate glass for indefinite storage. The vitrification facility utilizes two primary methods for separating radioactive materials from the bulk waste, which are ultrafiltration and ion exchange. Our project focuses on the ion exchange process. Our intention is to develop mass transfer and reactor design models to accurately describe the ion exchange process. To summarize our goals for this project, the following issues will be addressed: Model the ion flux and concentration gradient throughoutthe reactor using the spherical nature of the resin beads. Determine the rate equation associated with the ion exchange reaction. Size the ion exchange column according to required radioactivity levels for Low Activity Wastefeed. Determine loading time for lead column. Researching these issues will help us and our classmates better understand the overall ion exchange process, which is a separation process widely used throughout industry. Support for Issue Research Process Overview The primary concern for our process is the separation of radioactive Cesium-137 from the nonradioactive substituents in the waste stream. Hanford’s Pretreatment Facility utilizes ResorcinolFormaldehyde Resin to exchange 137Cs+ atoms for Na+ inside a series of packed ion exchange columns. Figure 1 illustrates the overall ion exchange process. 137 Cs Lead Lag Upflow Reagents NaOH, HNO3, H20 Polish Resin Rejuvenation Na+ Form Loading - Low Activity Waste (LAW) Elution – Highly Concentrated 137 Cs to High Level Waste (HLW) Figure 1: Cesium Ion Exchange Process Theuntreated waste enters the lead column and flows through lag and polishing columns before concentrated Cesium is sent to the High Level Waste (HLW) facility. The remaining waste is sent to the Low Activity Waste (LAW) melters for vitrification.The fourth column is kept in reserve in order to keep throughput constant while resin rejuvenation is being performed on fully loaded columns. Mass Transfer Resorcinol-Formaldehyde resin is comprised of resorcinol (1,3-dihydroxybenzene) units linked with methylene bridges as shown in Figure 2. 2 Figure 2: Resorcinol-Formaldehyde Resin Functional Groups (King et al, 2005) The combination of hydroxyl and alkyl groups activates the benzene ring toward electrophilic substitution reactions (King et al, 2005). Each resorcinol molecule has two available groups for cation exchange.Figure 3 describes the general reaction. Figure 3: General Electrophilic Ion Exchange Reaction The primary ion exchange reaction is accomplished between di-sodium substituted (Na form) resin and aqueous cesium.The resin is highly spherical and consistently sized as seen infigure 4 (King 2007). As a result, we will develop a mass transfer model for ion exchange around a sphere as a function of concentration. The concentration gradient between the Na+resin and 137Cs+in the waste feed will cause diffusion to occur between the two species, leaving 137Cs on the surface of the resin beads while Na+ atoms flow out the Low Activity Waste Stream. Figure 4: Spherical Resorcinol-Formaldehyde Resin (King 2007) 3 Reactor Design Although the exact configuration and internal structure of Hanford’s cesium ion exchange columns is proprietary, we will model our reactors after traditional packed bed reactors. As a result, we will consider the effects of concentration and pressure changes on the reaction rate as waste travels through the columns. The process is considered isothermal so temperature variations will not be considered. A reaction rate model will be developed to describe the kinetics inherent to the ion exchange process. Due to radioactivity requirements for the LAW feed, a majority of the radioactive cesium must be removed prior to exiting the polishing column. We will determine the required size of the ion exchange columns in order to meet this specification and the associated loading time for the lead column. Issue Justification Treatment and storage of nuclear waste is a continuing problem. The Hanford site has the largest stockpile of untreated nuclear waste in the world (Burgeson et al, 2006). The U.S. Department of Energy is committed to the safe cleanup and disposal of Hanford’s nuclear waste, as evidenced by the creation of the vitrification plant. Our project focuses on the most important part of pretreating the waste prior to vitrification. Researching this process allows us to develop models for both mass transport and reactor design. Modeling the diffusion within the column and determining the packed bed reactor specifications are directly related to our curriculum and provide benefits to ourselves as well as our classmates. Nuclear waste treatment is an example of ion exchange application in the real world. 4 Appendix A References Burgeson, I. E. , Deschane, J.R. , Cook, B. J. , Blanchard Jr. , D. L. and Weier, D. L. (2006) ‘Evaluation of Elution Parameters for Cesium Ion Exchange Resins’, Separation Science and Technology, 41: 11, 2373 – 2390. Fiskum, S. K. , Steele, M. J. , Blanchard, D. L. Jr. , (2006) ‘Small Column Ion Exchange Testing of Spherical Resorcinol-Formaldehyde Resin for 137Cs Removal from Pre-Treated Hanford Tank 241-An102 Waste’, Battelle – Pacific Northwest Division, Richland Wa. Hassan, N. M. , McCabe, D. J. , King, D. W. , Hamm, L. L. , Johnson, M. E. , (2002) ‘Ion Exchange Removal of Cesium From Hanford Tank Waste Supernates With SuperLig 644 Resin’ Journal of Radioanalytical and Nuclear Chemistry, Vol. 254, No. 1, pp. 33-40. King, D. W., (2007) ‘Literature Reviews to Support Ion Exchange Technology Selection for Modular Salt Processing’, Savannah River National Laboratory, Westinghouse Savannah River Company, Aiken, SC. King, D. W., et al, (2006) Reactivity of Resorcinol Formaldehyde Resin with Nitric Acid, Savannah River National Laboratory, Westinghouse Savannah River Company, Aiken, SC. 5