Identification

advertisement

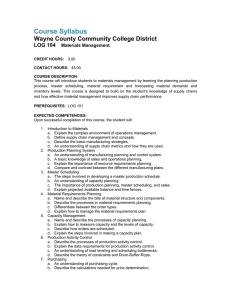

Identification Prerequisites Language Compulsory/Elective Text books and course materials Course Teaching methods Evaluation Criteria Course objectives Course outline Learning outcomes Economics and Management Postgraduate MGT 850 – Operations Management and Logistics– 3KU credits (6 ECTS credits) Fall 2014 Term Xumar Huseynova, xumar_huseynova@cbar.az Instructor Classroom/hours 122 Bashir Safaroglu str. (Downtown campus), Room # 12, Friday 18:30 – 21:00 Consent of instructor; Operations Management and Logistics English Compulsory Textbooks: Operations Management, Global Edition, 11/E by Jay Heizer. Barry Render - 2014, 888 p. e-book http://www.coursesmart.co.uk/IR/6698638/9780273787075?__hdv=6.8 2. Operations Management: For Competitive Advantage, 12/E by Richard Chase, Robert Jacobs, Nicholas Aquilano - 2006 Department Program Subject This course is carrying out by using traditional face-to-face classes. All course related materials including, but not limited to, syllabus, supplementary readings, course announcements, cases and assignments will be provided. x Case analysis x Group discussion x Experiential exercise (problems) x Lecture Course paper Others Methods Date/deadlines Percentage (%) 25 Midterm Exam 5 Class Participation 5 Activity 10 Case analysis 10 Problem solution 10 Team project 35 Final Exam (Project) 100 Total Generic Objective of the Course: To provide students with the core concepts, methods and techniques of operations management Specific Objectives of the Course: Introduction to operations management through global environment and Operations strategy, managing projects and forecasting demand To learn methods and tools to design operations Acquire some practical skills and managerial way of thinking of managing operations Gain three hours of credit towards graduation. This course is designed for MBA students. Examines problems encountered in planning, operating, and controlling production of goods and services. Topics include: quality assurance, production systems, project management, and inventory management, forecasting and capacity management, computer and quantitative models used in formulating managerial problems. This course is designed for the bachelor students. Desired learner outcomes will include understanding about What Operations management is o Differences between Services and Goods Production o Historical development of OM o Current issues of OM Developing missions and strategies o Competitive dimensions o Developing manufacturing Strategy o Operations strategy for Services The importance of project management o Starting projects o Time cost models o Managing resources Seven steps in forecasting methods o Demand management o Qualitative techniques o Quantitative techniques Defining a product and application of decision trees to product design o Steps of product design o Design for manufacturing o Design for services Total quality management o Quality Specification and Quality cost o Six sigma Quality o External Benchmarking for quality o Improvement Four process Strategies o Process Flowcharting o Types of processes o Measuring process performance The strategic importance of location o Issues in Facility location o Locating service facilities The strategic importance of layout decisions o Process layout o Product layout o Group technology o Fixed-position layout o Retail service layout Job design and Work Measurement o Job design decisions o Behavioral Consideration in Job Design o Physical Consideration in Job design o Work measurement and standards o Financial incentives plans Managing the Supply Chain o Measuring supply chain Performance o Outsourcing o Design for logistics o Global sourcing Managing Inventory o Definition of Inventory o Purposes of inventory o Independent versus dependent o Demand o Inventory systems The nature of Aggregate Scheduling o The aggregate Operations Plan o Aggregate planning techniques o Yield management Scheduling for short term o Priority rules and techniques o Shop floor control o Personnel Scheduling in services What is Just-in-Time? o JIT Logic o The Toyota Production system o JIT implementation requirements o JIT in services Maintenance and reliability decisions o Improve system reliability o o o o Week Date/Day (tentative) 1 09/19/2014 2 09/26/2014 3 4 10/03/2014 10/10/2014 Determine mean time between failure (MTBF) Distinguish between preventive and breakdown maintenance Describe how to improve maintenance Compare preventive and breakdown maintenance costs Topics Introduction to operations , The global Environment and Operations strategy Managing Projects Forecasting Demand /Product design Quality Management and International Standards/ Statistical Process Control Textbook/Assignments Ch.1 / Ch.2 [1] ]; Ch.1/ Ch.2 [2] Ch3, [1] Ch3 [2] Ch.4/ Ch5[1]; Ch.12/ Ch.5 [2] Ch. 6/ Supplement 6, [1]; Ch.7 [2] Ch.7/ Supplement 7, [1]; 5 6 10/17/2014 Ch.4 / Ch.10 [2] 10/24/2014 7 10/31/2014 8 11/07/2014 9 11/14/2014 10 11/21/2014 11 11/28/2014 12 12/05/2014 13 12/12/2012 14 12/19/2014 15 12/26/2014 16 Process Design/Capacity Planning Location Decisions Ch.8, [1] / Ch.10 [2] Layout Decisions Ch.9 , [1];Ch.5, TN 5. [2] Midterm Job Design and Work Measurement Ch.10, [1] TN 4.[2] Managing the Supply chain / Outsourcing as a Supply chain strategy Ch.11/ Supplement 11, 1]; Ch.9 [2] Managing inventory Ch.12, [1]; Ch.14 [2] Aggregate Scheduling, Material Requirements Planning & ERP Ch.13, 14 [1];Ch.13 [2] Scheduling for the Short Term Ch.15, [1]; Ch.16 [2] JIT, Lean operations and the Toyota Production System Ch. 16, [1]; Ch.11 [2] Maintenance and reliability Ch.17, [1] Final