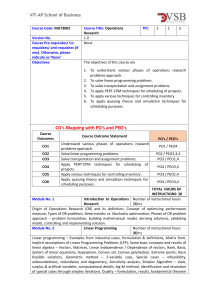

OM-Course plan.

MBA107 OPERATIONS MANAGEMENT

The purpose of the course is to familiarise the participants with the operations management function in the context of the increasing competition and advancements in the technological frontiers.

Participants are advised to read articles related to the topics, extensively.

Industrial visits and on line tours are part and parcel of the course.

A practical orientation in each and every activity is a must.

Discussion of as many cases as possible is highly advocated.

Participants are permitted to take the lead in all aspects.

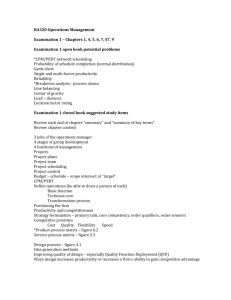

Session 1

Production as a functional area in business

Production vs. Operations

Manufacturing vs. service

History of OM and major contributors

Session 2

Decision areas in OM

Framework for managing operations

Strategic role of OM

Current issues in OM

Session 3

Case Study 1- The decision areas in OM

Discussion- OM practices in world class companies.

Assignment 1- The strategic role of OM with appropriate real world examples.

Session 4

Product development: Basic concepts

Product Design Process

Concepts: Robust design, Modular design, Value engineering, Concurrent engineering, Time based competition, Green manufacturing

Tools: CAD,CAM,CAE

Session 5

Case study 2

Discussion: Product development in select industries : Passenger car, Pharmaceuticals, Telecom

Assignment 2- New Product Development- Success and failures: Relevant cases with logical

Interpretation.

Session 6

Process design basic concepts: Cycle time, set up time, throughput rate,utilization,pacing

Types of process: Make -to-order, Make-to-stock, Assemble-to-order, single stage and multistage.

Product-process matrix

1

Session 7

Productivity: measurement, importance

Flow charts

Case Study 3.

Discussion: Process design at: a kirana, stationary shop, supermarket and organized retail outlet

Assignment 3-Prepare the flow charts of 5 different processes.

Session 8

Lay out design: Basic concepts

Types: Advantages and disadvantages of each

Line balancing, sequencing

Session 9

Case study 4

Discussion: Layout of your class room, Layout of a modern retail outlet, a shopping mall and a multispecialty hospital.

Assignment 4-“Facility layout is also a marketing problem in services”. Substantiate.

Industrial visit- Critically evaluate the process design and layout of the facility.

Session 10

Facility Location:Importance,Focus

Factors affecting location decision

BPO

Session 11

Methods for location selection: Factor rating, Break-even analysis, Centre of Gravity,

Transportation

Numerical problems

Session 12

Environmental Impact Assessment

Bio diversity and sensitivity

Sustainable and Responsible Development

Case Study 5

Discussion: Tata-Singur, Narmada Bachavo Andolan, Plachimada issues

Assignment 5: Review on major industrial belts in India.

Session 13

Inventory Management: Importance

Inventory classification: ABC,VED,FSN,GOLF,XYZ,HML,SDE

Components of inventory cost: Item cost, ordering cost, carrying cost, set up cost

Session 14

Inventory models: Simple EOQ,EOQ with quantity discounts,Probabilistic models

Numerical problems

2

Session 15

Purchasing:centralized vs.decentralised, Tenders,quotations, CPC

Stores management: coding,cycle counting,inspection,sampling

P System and Q system

Vender Management

Session 16

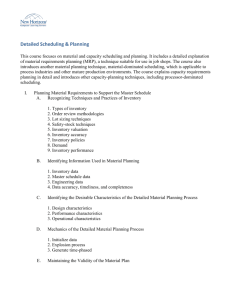

Materials Requirement Planning(MRP-I)

Manufacturing Resource Planning(MRP-II)

Enterprise Resource Planning(ERP)

Case study 6.

Assignment 6: Work out problems on inventory models

Session 17

Quality Management; Definitions

Cost of quality

Quality Gurus

Strategic role of quality

Session 18

Quality system standards: ISO 9000, ISO14000

BIS:Role and responsibilities.

Statistical Process Control(SPC): Control chart for variables and attributes

Acceptance sampling ; OC Curve, AQL,LTPD

Session 19

TQM:Concepts,Pyramid

TQM Tools

Session 20

Case study 7

Discussion: Japanese management and quality

Assignment 7: Discuss the quality concepts mooted by the ‘Gurus’ from time to time.

Session 21

Supply Chain Management: Concepts

Views: Push-pull view, Cyclic view

Vertical Integration

Session 22

Case Study 8

Assignment 8: e-SCM models used by leading companies

Discussion: Emerging trends in SCM

Session 23

Job design: Use of labor standards

Work study

Labour specialization, Job expansion, Self Directed Teams

3

Session 24

Time study methods: Direct time study, work sampling

Numerical problems

Case Study 9

Assignment 9: Problems on Time Study

Session 25

Maintenance management and Reliability

Cost of maintenance

Toyota Production System

Session 26

Total Productive Maintenance(TPM)

Case study 10

Discussion: Emerging trends in Maintenance management

Assignment 10: Read the book “The Toyota Way” and submit a summary.

Session 26

Scheduling Decision

Capacity planning: concepts, importance

Aggregate Production Planning

Capacity options: Demand option supply option, mixed options

Session 27

Short term scheduling: importance

Forward and backward scheduling, sequencing

Theory of Constraints

Case study 11

Session 28

Project Management

Project planning, scheduling and controlling,

PERT and CPM

Assignment 11: Problems on PERT and CPM

Session 29

Simulation

Queuing

Transportation

Session 30

World Class Manufacturing

Lean Manufacturing, Agile Manufacturing

Computer Integrated Manufacturing(CIM)

Assignment 12: World Class Manufacturing Practices.

Session 30- 40

Seminars

4

5