2. Description of the different water filters

advertisement

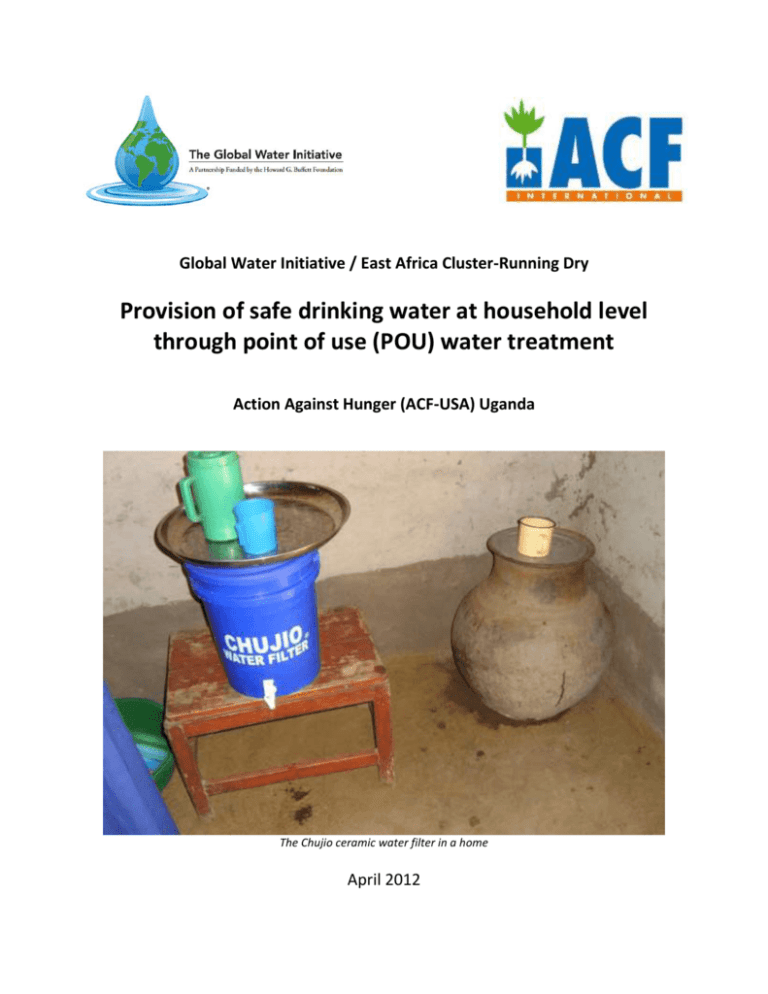

Global Water Initiative / East Africa Cluster-Running Dry Provision of safe drinking water at household level through point of use (POU) water treatment Action Against Hunger (ACF-USA) Uganda The Chujio ceramic water filter in a home April 2012 TABLE OF CONTENTS Table of Contents Table of Contents ................................................................................................................................. 1 1. Background ....................................................................................................................................... 2 2. Description of the different water filters ......................................................................................... 4 2.1. BIOSAND WATER FILTER ........................................................................................................ 4 2.1.1. How does the filter work? .................................................................................................. 5 2.1.2. Operation and maintenance .............................................................................................. 8 2.1.3. Contaminant removal efficiency of the biosand filter ....................................................... 9 2.1.4. Advantages and limitations of the biosand filter ............................................................. 10 2.2. CERAMIC WATER FILTER ......................................................................................................... 11 2.2.1. How does the filter work? ................................................................................................ 11 2.2.2. Operation and maintenance ............................................................................................ 12 2.2.3. Contaminant removal efficiency of the ceramic filter ..................................................... 14 2.2.4. Advantages and limitations of the ceramic filter ............................................................. 14 2.2.5. Community voice: ceramic filter has improved the health of Okello Joel ....................... 15 2.3. TIVA WATER FILTER ................................................................................................................. 17 2.3.1. How does the filter work? ................................................................................................ 19 2.3.2. Operation and maintenance ............................................................................................ 19 2.3.3. Contaminant removal efficiency of the Tiva filter ........................................................... 21 2.3.4. Advantages and limitations of the Tiva filter ................................................................... 21 2.3.5. Community voice: Tiva water filter have improved the health of Jennifer ..................... 21 3. Comparaison between the three tested water filters ................................................................... 23 4. Main results and lessons learnt...................................................................................................... 26 5. Conclusions and recommendations ............................................................................................... 27 Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 1 of 27 1. BACKGROUND Since 2007, ACF International has implemented water and sanitation projects in over 150 villages in Otuke district in Northern Uganda. This region was affected by the 20 year long civil war that led to displacements of communities into camps. The war affected deeply communities who lost source of livelihoods and capacity to meet the basic necessities. After cessation of hostilities in 2006, people began to return to their original homes where a limited number of functional water and sanitation facilities were present. As a result of the lack of sanitation facilities (latrine coverage was at 5%), open defecation was a common practice with the subsequent contamination of open water sources with faecal matters. Community members were constraint to drink open water sources (rivers, streams, lakes, swamplands) which were contaminated with human and animals’ faeces as communities were using these sources for drinking, bathing and watering animals. Such situation caused a high prevalence of waterborne diseases, mainly diarrheal diseases, resulting into morbidity and mortality especially for underage children. Since then, ACF assisted returnee communities with the construction and rehabilitation of safe water points (mainly boreholes) and the implementation of sanitation and hygiene activities. The access to safe water and sanitation facilities in the project area increased and reaches currently 65% and 61% respectively. In spite of the evident improvement in safe water coverage, there are still people drinking unsafe water due to the following: Not all villages could be provided with a safe water source due to limitation in funds. In fact, a new water point (borehole) cost about 6,500 USD. The type of settlement is dispersed with the consequence that often people have to walk long distances to safe water sources. People prefer to use contaminated water from streams and traditional holes in the village than walking long distance to a safe water source. Low sanitation coverage and open defecation practices induces contamination of open water sources. Due to high poverty levels, people cannot afford chlorine tabs. As an alternative to the costly new borehole (6,500 USD) or less safe hand dug well (3,000 USD), ACF piloted the rehabilitation of traditional water points for communities that had missed out on a safe water source. However this low cost technology (150 USD) compromises the quality of water, especially the faecal contamination, and increases the risk of water borne diseases. Although waterborne diseases are easily and quickly spread from person to person, the transmission of these diseases can be controlled through practical and low cost methods. Filtration, boiling, and the addition of household bleach are ways to remove harmful contaminants from water and ensure that households consume clean water. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 2 of 27 ACF decided to address the salient water quality issues by distributing water filters to families near unsafe water sources, starting with the distribution of 139 biosand filters, then 1,113 ceramic filters, and currently 160 Tiva filters. The water filters treat the water and make it free of coliforms and make it safe for drinking and hence diarrheal diseases would decrease. The project was funded by the GWI project by Howard Buffet Foundation and is overseen by the ACF WASH team that was trained on the technology. At community level, the project is monitored by the WASH team and supported trained Village health teams and local leaders. Access to clean filtered water improved the overall health and quality of life of communities and made them more productive. Enrolment in schools was maintained as children suffering from waterborne illnesses who would often miss school now attended regularly. Healthy adults are more often able to work or care for their children. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 3 of 27 2. DESCRIPTION OF THE DIFFERENT WATER FILTERS ACF piloted 3 types of water filters in the project area: biosand filter, ceramic filter, and Tiva filter (this last one is an improvement of the classical biosand filter). 2.1. BIOSAND WATER FILTER Figure 1: Biosand filter in a home ACF has so far distributed 139 biosand filters in 11 villages. In Uganda, this filter costs 60 USD and can be easily found everywhere as they are locally made. The biosand filter is a modified form of the traditional slow sand filter in such a way that the filters can be built on a smaller scale and can be operated intermittently. These modifications make the biosand filter suitable for household or small group use since it can be produced locally anywhere in the world using materials that are readily available. The biosand filter is largely used around the world and is has been recommended by various international organizations such as WHO. This type of filter kills bacteria through 3 main processes to make water safe for drinking which include: Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 4 of 27 1. Biological Action where useful bacteria trapped on the sand bed predate on pathogens in the water. 2. Mechanical action/ adsorption where the granite stone particles attract and trap any bacteria to itself using its ionic properties. 3. Starvation and suffocation through straining the bacteria deep in the granite stone, pathogens are starved to death while others die due to lack of oxygen. The biosand filter is composed by the following elements: Lid Prevents contaminants from entering the filter Diffuser Plate Protects the biological layer from damage when water is poured into the filter Outlet Pipe – 6 mm (¼”) inner diameter (ID) Conducts water from filter base to outside Sand Layer – 40 to 50 cm deep Traps organic and inorganic material at the top of the filter media Separating Gravel Layer – 6 mm (¼”) size – 5 cm deep Prevents sand from plugging under drain gravel Under drain Gravel Layer – 12 mm (½”) size – 5 cm deep Promotes flow of water into outlet pipe 2.1.1. How does the filter work? A bucket of contaminated water is poured into the top of the filter. The water simply flows through the filter and is collected in another storage container at the base of the spout. A biological layer (often called the “schmutzdecke” or “biolayer”) of slime, sediment and microorganism develops at the sand surface. Pathogens and suspended material are removed through various physical and biological processes that occur in the biolayer and sand. When water is flowing through the filter, oxygen is supplied to the biolayer by the dissolved oxygen in the water. During pause times, when the water is not flowing, the oxygen is obtained by diffusion from the air. If the standing water layer is kept shallow, enough oxygen is able to pass through to the microorganisms to keep them alive and effective. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 5 of 27 The biosand filter has six different distinct zones as shown below: Inlet Reservoir: Space above the sand and gravel media which allows for a full pail of water (20L). Standing Water: Oxygen diffuses through the standing water to the biolayer. Biolayer: Layer of slime, sediment, and microorganisms which develops at the top 1-2 cm (0.4-0.8”) of the sand surface. Biological Zone: Develops at the top 5-10 cm (24”) of the sand surface. The sand absorbs pathogens, iron, and other small particles. Sand Zone: Contains virtually no living microorganisms due to lack of nutrients and oxygen. Gravel Zone: Holds the sand in place which protects the outlet pipe from clogging and allows for the smooth flow of water. The treatment of the water is done through the following steps: 1. Beginning of the run The inlet water contains dissolved oxygen, nutrients and contaminants. The high water level pushes the water through the filter. After passing through the diffuser plate, the inlet water mixes with the standing water. The standing water is lower in oxygen, nutrients, and pathogens than the inlet water because they were consumed during the pause period. The inlet water provides the oxygen required by the microorganisms in the biolayer. Sediment and larger pathogens are strained out at the top of the sand. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 6 of 27 2. Halfway through the run The water level in the reservoir goes down as it filters through the sand. The flow rate will slow down because there is less pressure. Sediment and larger pathogens are strained out and they partially plug the pore spaces between the sand grains. This also causes the flow rate to slow down. 3. End of the run The water flow finally stops. The standing water layer will be at the same height as the outlet of the pipe. Pathogens in the inlet water are consumed and those from the previous run which were partially consumed are more completely broken down. Pathogen removal increases with time because of the slower flow rate and the decreased size of pore openings. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 7 of 27 4. Pause period between two runs Some oxygen from the air passes through the standing water to the biolayer. The pause period allows time for microorganisms in the biolayer to consume the nutrients and pathogens in the water. The flow rate through the filter is restored as they are consumed. If the pause period is too long, the biolayer will eventually consume all of the pathogens and nutrients and eventually die off. This will reduce the removal efficiency of the filter when it is used again. A 6 to 12 hour pause period is recommended with a minimum of 1 hour and a maximum of 48 hours. Microorganisms in the sand zone die off due to the lack of nutrients and oxygen. 2.1.2. Operation and maintenance Water source The biosand filter can use any water source such as rainwater, deep groundwater, shallow groundwater, rivers, lakes or other surface waters. The source should be the cleanest available since the filter is only able to remove a certain percent of the pathogens. If the source water is highly contaminated, the outlet water may still have some contaminants. The same source of water should be used consistently because the biolayer cannot quickly adapt to different water quality. Over time, the microorganisms in the biolayer become used to a certain amount of contamination from the source water. If different water source with a higher level of contamination is used, the biolayer may not be able to consume all of the pathogens. It may take the biolayer several days to adapt to the new source water and level of contamination. Experiments have shown that the largest portion of bacteria from a more contaminated water source water show up in the filtered water the next day. The turbidity (cloudiness in water) of the water source is also a key factor in the operation of the filter. Nephelometric turbidity units (NTU) measure the level of suspended matter (organic and silt particles) in water. If the turbidity is greater than 50 NTU, the water source should be settled or strained before it goes though the biosand filter. Establishing the biolayer The biolayer is the key pathogen removing component of the filter. Without it, the filter removes some contamination through screening of the sediment and microorganisms (only 30-70% removal efficiency). The ideal biolayer will remove 90-99% of pathogens. It may take up to 30 days to establish the biolayer and during that time, both the removal efficiency and the oxygen demand will increase as the biolayer grows. The biolayer is not usually visible – it is not a green slimy coating on top of the sand. The water from the filter can be used during the first few weeks while the biolayer is being established, but disinfection, as always, is recommended during this time. The time needed to establish the biolayer may vary as some filters require a shorter or longer period of time depending on the source of water being used. Flow rate The biosand filter has been designed to allow for a filter loading rate (flow rate per square meter of filter area) which has proven to be effective in laboratory and field tests. This filter loading rate has been determined to be not more than 600 liters/hour/square meter. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 8 of 27 The recommended flow rate for the standard concrete biosand filter used by ACF is 0.6 L/minute measured when the inlet reservoir is full of water. If the flow rate is much faster, the filter may become less efficient at removing pathogens. If the flow rate is much slower, the household user may become impatient and not use the filter at all even though the filter is working well at removing pathogens. Since the flow rate is controlled by the size of the sand grains, it is very important to well select and prepare the sand. Pause period The biosand filter is most effective and efficient when operated intermittently and consistently. A recommended pause period is 6 to 12 hours with a minimum of 1 hour and a maximum of 48 hours. The pause period is important because it allows time for the microorganisms in the biolayer to consume the pathogens in the water. As the pathogens are consumed, the flow rate through the filter may be restored. If the pause period is extended for too long, the microorganisms will eventually consume all of the nutrients and pathogens and then eventually die off. This will reduce the removal efficiency of the filter when it is used again. Standing water depths Correct installation and operation of the biosand filter has a water level of approximately 5 cm (2”) above the sand during the pause period. A water depth of greater than 5 cm (2”) results in lower oxygen diffusion and consequently a thinner biological zone. A high water level can be caused by a blocked outlet pipe or by an insufficient amount of sand. A water depth less than 5 cm (2”) may evaporate quickly in hot climates and cause the biolayer to dry out. Maintenance There is some key maintenance tasks that are required after a filter has been installed and used regularly: The outlet tube will become contaminated during normal use via dirty hands, animals, or insects. The outlet tube must be cleaned regularly with soap and water or a chlorine solution. The inside of the treated water storage container must be also cleaned with soap and treated water when it looks dirty, at least once a month. It is important to not pour chlorine into the top of the filter as it will kill the biolayer. Over time, the pore opening between the sand grains will become clogged with sediment. As a result, the water flow rate through the filter will slow down. To clean the filter, the surface of the sand must be agitated to re-suspend the sediment in the standing water. The dirty water can be removed using a small container. The process can be repeated as many times as necessary to regain the desired flow rate. After cleaning, it will take the biolayer up to a week to re-establish itself and return the removal efficiency to its previous level. 2.1.3. Contaminant removal efficiency of the biosand filter Biosand filters have been shown to remove 90-99% of pathogens found in water. There are four processes that remove pathogens as the water passes through the filter: - Mechanical trapping: sediment and pathogens are physically trapped in the spaces between sand grains. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 9 of 27 - Predation: pathogens are consumed by other microorganisms in the standing water and biolayer. - Adsorption/Attraction: pathogens become attached to the sediment and the sand grains. - Natural death: pathogens finish their life cycle or die because there is not enough food and oxygen for them to survive. The filter has been tested by various government, research, and health institutions, as well as by non-governmental agencies in both laboratory and field settings (Duke, 2006; Stauber, 2005 and 2006; Palmateer, 1999; Ngai, 2007; Muhammad, 1997; Collins, 1998). Overall, these studies have shown that the biosand filter removes: - > 97% of E. coli - an indicator of faecal contamination - > 99% of protozoa and helminths - 80-90% of viruses - 50-90% of organic and inorganic toxicants - 90-95% of iron - Most suspended sediments Based on slow sand filter research, the biosand filter may also remove some heavy metals. There is also a design modification known as the “KanchanTM Arsenic Filter” that is effective in removing both pathogens and 85-90% of arsenic from water. ACF conducted water quality tests to monitor the quality of water from this type of filter. Results showed that greater percentages of the analyzed samples from these filters are contaminated indicating presence of E. coli. In 2009, 1 year after filter distribution, only 20 out of 121 tested households showed zero coliform after filtration. In 2012, 4 years after filter distribution, a water quality analysis conducted in 1 of the 6 biosand filter still in use, showed the presence of E. coli (2 E.coli/100ml) in the filtered water. 2.1.4. Advantages and limitations of the biosand filter The advantages are the followings: - Durable and long-lasting. - Can produce up to 50-80 litres of water per day. - Constructed from local materials. - Removes most pathogens and sediments. - Can be modified for arsenic removal (KanchanTM Arsenic Filter). - Opportunity for local entrepreneurs to manufacture and sell the filters. The limitations of the biosand filter are the followings: - Heavy and difficult to move. - Biolayer takes up to 30 days to develop to maturity. - Routine cleaning can harm the biolayer and decrease effectiveness. - Source water with high turbidity (> 50 NTU) will cause filter to clog more frequently and require more maintenance. - Not as effective against viruses. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 10 of 27 - Cannot remove all colour. - Best filter performance requires a consistent water source. 2.2. CERAMIC WATER FILTER Figure 2: Ceramic filter in use in a home in Tedam village ACF has so far distributed 1,113 ceramic filters to 39 villages. No ceramic water filters are available in Uganda. ACF tested the “chujio” ceramic water filter, imported from Nairobi in Kenya. The cost of this filter is 30 USD (transport and taxes included). Ceramic water filters are simple, inexpensive and highly effective water filtration systems that clean water using a ceramic pot painted with a solution called colloidal silver. When used properly, filters eliminate 99.98% of disease-causing organisms from water, making it safe to drink (PFP, 2006). 2.2.1. How does the filter work? A colloidal silver ceramic filter provides potable water by filtering out dangerous microorganisms. The filter consists of a ceramic pot, called the filter element, placed inside a plastic bucket, called a receptacle (see Figure 3). The pot is painted with a special solution called colloidal silver, which kills bacteria. Tiny pores in the ceramic pot allow water – but not parasites or bacteria - to pass through. The bucket has a lid to help prevent contamination and a plastic tap to facilitate access to the filtered water. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 11 of 27 The filter has the capacity to meet, on average, the daily drinking water needs of a family of 6 people. It filters water at the rate of 1 to 2.5 litters per hour. Figure 3: Ceramic filter – filtration process and different parts of the filter 2.2.2. Operation and maintenance The operation and maintenance of the ceramic filter is illustrated in Figure 4. It is important to not use soap to clean the clay receptacle and to not filter chlorinated water through the filter element except when cleaning. Over time, chlorinated water will erode the silver and may lessen its antibacterial properties. The filter must be cleaned once each month or when the flow rate slows noticeably. Scrubbing the ceramic pot more often will increase the likelihood of contamination. In addition, each time the ceramic pot is scrubbed, a small amount of clay/silver is lost. It is important to touch only the rim when moving the ceramic pot and hands must be clean. The ceramic pot must be replaced when it becomes cracked (even the smallest crack may allow bacteria to pass through) and when the flow becomes too slow and is not increased by cleaning. If the filter is maintained properly, it should last for approximately three to five years. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 12 of 27 Figure 4: How to use and clean the ceramic filter Figure 5: Cleaning the ceramic filter Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 13 of 27 2.2.3. Contaminant removal efficiency of the ceramic filter When contaminated water is poured into the filter, microorganisms become trapped in the ceramic pot and only potable water is allowed to flow through the spigot. Protozoa, helminths, and most bacteria are too big to pass through the pores and are effectively filtered out. Bacteria that are small enough to pass through the pores are inactivated by the colloidal silver and become incapable of reproducing. Although the pores are very tiny, they are not small enough to filter out most viruses. The colloidal silver may inactivate some viruses, although more research is needed to determine its effectiveness against viruses. The filter is not effective in removing metals or pesticides. ACF conducted water quality tests to monitor the quality of water from this type of filter. Results showed that in all the tested households, the filtered water was free from E. coli. Water analysis done in 4 years old filters showed the same excellent results. 2.2.4. Advantages and limitations of the ceramic filter The advantages of the colloidal silver ceramic water filter are the followings: - Proven reduction of bacteria and protozoa in water by about 95%. - Removes sediment. - Acceptability to users because of the simplicity of use. - Easy to move and transport. - Filtered water is stored directly in the bucket containing the filter. The limitations of this kind of filter are: - Lasts up to 3-5 years if properly operated in less turbid water. - Does not remove viruses or chemicals. - May clog easily. - Filter and receptacle must be cleaned regularly, especially after filtering turbid water. - Is fragile and may broke or crack easily. - Low flow rates 1-2.5 litres/hour. - Not manufactured in Uganda. - The storage capacity is not suitable for households with a large population. - May get smaller cracks that allow passage of bacteria due to frequent scrubbing with time which decreases efficiency. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 14 of 27 Figure 6: Households in Obui receiving their ceramic filter 2.2.5. Community voice: ceramic filter has improved the health of Okello Joel Camkwoki is a village in Otuke district (Alangi parish in Orum sub-county) which has 47 households and a total population of 213. “The village has for long been facing challenges of access to clean water for drinking, washing white clothes as well as long distance walk of not less than 3km in search for clean and safe water every day” says Mr. Okello Joel, the VHT of the village. Since their return from the internally displaced people’s camp, most of the water springs were non functional except one that was dirty and when it rains get filled up with runoff water, explained Mr. Joel. “With support from ACF, we mobilised our community, dug the channel and improved on the existing water point to prevent the runoff water entering the water point and also to improve on the flow of the water” adds Mr. Joel. Figure 7: Traditional water point improved by ACF in Camkwoki Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 15 of 27 “After several visits made by the ACF WASH team and discussions with the community members, we were made to know even Traditional Improved Water Point is still not safe enough for drinking hence the idea of Point Of Use (POU) ceramic water filters were introduced to the community. A total of 47 filters were distributed to all the households in the village. The community members were later trained on how to use and maintain the filters. Ceramic filters effectively remove E.coli and reduce turbidity in untreated tap water. Ceramic filters are portable and can easily be moved from one place to another and there are not many procedures involved in installing the facility and you simply pour water and collect. Ceramic filters also remove the brown colour in water”. Figure 8: Community members receiving their ceramic filter in Camkwoki “As I talk there is great reduction in the prevalence of diarrhoea and now members of the community were able to buy and maintain white clothes as never before. As a matter of fact access to clean water has never been made easy like this. In my village the EVIs are best example I can tell of the benefit of this. They can afford to walk the short distance and filter their water at home”. With confidence Joel says, “Together we can stop the long walk in search for clean and safe water.” Figure 9: Ceramic filter in use at the home of Mr. Okello Joel in Camkwoki village Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 16 of 27 2.3. TIVA WATER FILTER Figure 10: A Tiva water filter in a home ACF has so far distributed 160 Tiva filters to 7 villages. This filter costs 50 USD (included transport and training) and is available in Kampala. The company deliver the filters everywhere in the country. The Tiva water filter is a modified form of the biosand filter. The Tiva filter system relies on proven technology that has been used world-wide for over 15 years. The natural, laboratory tested, microgranite filter particles, measured to an exact dimension, create a filter media that harnesses the power of science to trap and kill bacteria, viruses, and parasites. The result is pure water that can be used for drinking, cooking, cleaning and personal hygiene. The Tiva water filter is composed by the following elements: - Plastic lid: prevents contaminants from entering the filter. - Filter tray: together with the filter cloth 1, they remove the biggest impurities and protect the biological layer from damage when water is poured into the filter. - Storage containers: 1 inner container and 1 outer container, both have up to 20 litres capacity. - Cloth filters (micro-mesh cloths): remove the smallest visible impurities and make water clean and clear. The first cloth is put up to the filter tray (coarse filter cloth 1). The second one is put up to the filter medium (micro filter cloth 2). - Filter medium: it contains laboratory tested particles that kill harmful organisms. The micro‐granite filter medium is designed to purify thousands of liters of water, but its life may vary depending on the quality of water input. The 9 kg micro-granite filter medium fills the space between the micro filter cloth 2 and the sand separator. - Sand separator: prevents particles of filter medium from plugging the clean water exit tube. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 17 of 27 - Clean water exit tube: 50 cm long – conducts water from filter base to the outer container. - Faucet: tape specially designed to be resistant. Figure 11: The 2 cloth filters of the Tiva water filter Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 18 of 27 2.3.1. How does the filter work? The principle is the same than the one described for the biosand filter. The main difference between the biosand and the Tiva filter is that the Tiva water filter gets 40 liters storage capacity and 2 cloth filters which remove the smallest visible impurities before the water enter in the filter medium. 2.3.2. Operation and maintenance Before regular usage Before using the filter for the first time, the upper container has to be filled with 20 liters of water. In about 8 to 10 hours, the entire water would have passed from the inner to the outer container through both filter cloths and the micro‐granite filter medium. Then, all the water from the lower container has to be empty out. The process must be repeated until water is clear. This will rinse out any dust in the micro‐granite filter medium. The Tiva filter is now ready for use. Using the filter For using the filter, up to 20 litters of dirty water is poured into the Tiva water filter system and the filtration process purifies the water while the household tends to other duties. It’s convenient since the 20 litres water storage container allows the household to access up to 40 litters of pure water each day. It is ready to use when needed. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 19 of 27 To ensure a safe supply of drinking water, it is important to add water to the filter on a daily basis. As for the biosand, the water level above the filter medium must be always present. Cleaning the outer storage container and the plastic faucet It is most important that keep the outer storage container clean. If any bacteria or algae get into the outer container it can become very contaminated– it is warm and wet inside, which creates an environment that grows lots of bacteria and algae. The inside of the outer storage container and the plastic faucet should be cleaned with a brush or firm clean cloth and soapy filtered (or boiled) water every two weeks. Once cleaned, the outer container should be rinsed with fresh filtered or boiled water to remove the soap. After cleaning, the plastic receptacle should be air dried. When it is completely dry, any remaining water borne bacteria and pathogens will die. Cleaning and replacing the filter cloths The filter cloths must be cleaned as often as necessary to release the dirt and dust trapped on the filter cloths and to prevent the flow rate from dropping too low. To clean, they simply have to be hold under water and cleaned with a soft brush. The filter cloths should not be exposed to soapy water because it is hard to rinse off and may make the water taste bad. In case the filter cloths get too dirty, they may be replaced for just a few shillings. Figure 12: Distribution of Tiva filters in Adwirpida village Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 20 of 27 2.3.3. Contaminant removal efficiency of the Tiva filter Water from the Tiva Water filter has been tested and Certified by UNBS for drinking using the standard for drinking potable water for ISO and Uganda standards. ACF conducted water quality tests to monitor the quality of water from this type of filter. Results showed that in all the tested households, the filtered water was free from E. coli. 2.3.4. Advantages and limitations of the Tiva filter The advantages of the Tiva water filter are the followings: - It’s lighter than the bulky original biosand filters. - Removes most pathogens and sediments. - It’s plastic and doesn’t break easily. - Thanks to the cloth filters, Tiva filter does not clog easily when filtering turbid water. - Produces at least 60 litres of water per day. - May last over 10 years. - Easy to use and maintain. The limitations of this kind of filter are: - There is the need to maintain a certain amount of water in the filter to maintain the biolayer. - Biolayer takes up to 30 days to develop to maturity. - It takes time for the smell to be completely unnoticed. - The sand and other components are not readily available in the project area (only Kampala). - It does not cool the water as compared to the ceramic water filter. 2.3.5. Community voice: Tiva water filter have improved the health of Jennifer Mrs. Jennifer Okwir, a village member from Rudagulu village in Otuke district (Oluro parish, Ogor sub-county), told us her experience of using Tiva water filter since the time she received it. The village has 35 households and a population of 165 people. All village members use 2 unprotected water pints for their water supply, distant about 1km from the village centre. “The fact remains that both water points are not safe” says Mrs. Jenifer Okwir. “Since the distribution of the Tiva water filter, there has been a great change mainly in the colour and taste of the filtered water. On delivery the ACF team trained us on how to use and maintain the facility. If I compare this type of filters with ceramic water filters which were distributed to our neighbouring village Tedam, Tiva filter is better. It can be used as a water filter and storage at the same time, something that never existed before. At my place I have trained my children on how to use it, since then I have never had less than 20 litters of clean and safe drinking water in a day” says Jennifer. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 21 of 27 Figure 13: The traditional well from which Jennifer collects drinking water “At the time of the training I understood the concept so quickly that I have become a model in using the water filter and can ably train my fellow women. The few village household who never got the facility were told that each complete set of Tiva water filter costs 130,000 Uganda shillings and most of them were willing to save some money and acquire one” says the VHT of the village, Mr. Francis Adina, who adds “Now we can even wash white clothes, drink clean, safe and clear water which was a dream for those without bicycles.” Figure 14: Jennifer (left) and community members (right) assembling their Tiva water filter after training Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 22 of 27 3. COMPARAISON BETWEEN THE THREE TESTED WATER FILTERS ACF has distributed so far 1,412 water filters: - 139 biosand filters in 2008, - 1,113 ceramic filters from 2008 to 2012, - 160 Tiva filters in 2012. Post distribution monitoring surveys conducted by ACF in 2009, 2011 and 2012 show that: - A lot of biosand filters were abandoned by the beneficiaries. One year after the distribution, 90% of the distributed filters were in use. Four years after the distribution, only 6 biosand filters were still in use (4% of the distributed biosand filters). - A lot of ceramic filters get broken. One year after the first distribution, 35% of the distributed ceramic filters were broken. In 2012, 45% of the households visited get their ceramic filter broken. All the non broken ceramic filter were used, even 4 years after their distribution. - Tiva water filters were well accepted by the beneficiaries. Three months after their distribution, all the distributed filters were in good condition and in use. Even if this kind of filter is the one preferred by the beneficiaries, it is too early to evaluate their sustainability on the longer term. - The biosand filter is generally cleaned when all the water is drained (for the upper part of the filter) or when it is blocked (for the filter media). The ceramic filter is generally cleaned when all the water is drained (33%), weekly (21%), when it is blocked (19%), or daily (14%). The Tiva water filter is generally cleaned once a month (33%) or weekly (32%). - The mother is the person generally responsible for cleaning the filter. - Difficulties experienced during the cleaning of the filter are the following: - The filter is too delicate to handle, especially for the ceramic filter (60-76% of households interviewed with a ceramic filter; about 50% for the Tiva and biosand filters). - The procedure is tedious (about 30% of households interviewed – the percentage is similar for the 3 types of filters). - The filter is heavy, especially for the biosand (50% of households interviewed with a biosand filter; 13% for Tiva; and only 2% for ceramic). - The biosand filter is too high (33% of households interviewed with a biosand filter). - Half of households refill their filter daily; about 30% refill their filter whenever it is empty. - The quantity of water stored at home is generally 20L (50-70% of households), following by 10L (20% of households) and 40L (10%). Very few households store 60-80L. - The quality of water improves after filtration, but the quality of water often deteriorate in the storage clay pot were households store their filtered water. This shows the need to insist on proper hygiene training and sensitization on this matter. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 23 of 27 Figure 15: Discussion with a 2008 biosand filter beneficiary (left) and an abandoned biosand filter (right) Figure 16: A ceramic filter put to good use (left) and a ceramic filter packed and not in use (right) Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 24 of 27 The brief comparison between the different types of water filters is given in the table below. Cost Availability Lifespan Quantity of water produced per day Removal capacity Solidity O&M Limitations Acceptance Biosand water filter Ceramic water filter Tiva water filter 60 USD Can be easily locally fabricated May last over 10 years Can produce up to 50 80 litres of water per day. (flow = 36 l/h) 30 USD 50 USD Imported from Nairobi Kampala 3-5 years May last over 10 years Cannot exceed 20 litres of water per day. (flow = 1-2 l/h) Produces at least 60 litres of water per day. - Removes most pathogens only if well used and if water sources is <50 NTU. - Can have turbid filtrate. Solid but heavy, difficult to move/transport. Bulky – hard to transport and move while cleaning. Its pores clog very fast hence blocking the filter and reducing its life span. Its extreme depth makes it difficult to wash the inside. Must be regularly used with pause period 6 to 12 hours. Need an additional storage container for the filtered water with high risks of contamination. Acceptance can be difficult, especially EVIs. - Very effective in - Very effective in eliminating pathogens. eliminating pathogens. - It filters irrespective - It filters irrespective of the water source of the water source (i.e. no limitation in (i.e. no limitation in NTU). NTU). - Has pure filtrate. - Has pure filtrate. Fragile, breaks easily, Solid and can be easily but very easy to moved/transported. move/transport. Easy to maintain and clean, but needs frequent cleaning when using turbid water source. Easy to maintain and clean. Does not clog easily when filtering turbid water. Need to be regularly filled as the storage capacity of this filter is limited. Must be regularly used with pause period 6 to 12 hours. Relatively easy to accept and adopt. Easy to accept and adopt. People appreciate the storage Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 25 of 27 capacity of the filter (they can easily pour 1 jerry can). Encountered problems - Leaks. - Its filter tube always get block when filters’ arrangement is disturbed. - Algae growth. - Tap is point of weakness. - No local spares available in case of repair. - Presence of smell during the first weeks of using the filter. 4. MAIN RESULTS AND LESSONS LEARNT Point of use water filters increased the access to clean water at household level. The biosand filter didn’t have a great success among the beneficiaries due to his bulkiness and maintenance issue (the manipulation for cleaning the filter media is not easy). Additionally to this, the biosand filter doesn’t have any storage capacity. Few months after distribution, a few beneficiaries abandoned this type of filter. Water analysis results showed that greater percentages of the analyzed samples are indicating presence of E. coli (about 2 E.coli/100ml). The lack of storage capacity contributes also to increase water contamination at storage level after filtration. Due to these issues, ACF decided to stop distributing biosand filter in its project area. The ceramic water filter was well appreciated by the beneficiaries. The maintenance is easy and it has a storage capacity of 1 bucket. The most appreciated by the beneficiaries is the fact that thanks to the ceramic pot, the filtered water is cool. All water quality analysis conducted in this type of filter indicated the water was free from faecal contamination after filtration. The main negative points of the ceramic filter are the fact that this type of filter is not manufactured in Uganda and the ceramic pot is very fragile and need extra care. The Tiva water filter was also well appreciated by the beneficiaries. This type of filter is an improvement of the classical biosand filter: the principle is the same, it is not bulky and the maintenance has been simplified thanks to the 2 filter cloths. The storage capacity of this filter is well appreciated by the beneficiaries who can pour 1 full jerry can (20L) into the filter. All water quality analysis conducted in this type of filter indicated the water was free from faecal contamination after filtration. For all the above reasons, ACF decided to move on with the Tiva water filter which has less fragility, better storage, less bulky, and is locally manufactured. At the moment, it is too early to make real conclusion on the sustainability of this type of filter. Results given from the post distribution monitoring conducted every 6 months will give us a better picture on the sustainability of this type of filter. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 26 of 27 The storage of filters doesn’t favour cooling as opposed to the traditional clay pot system preferred by the users. However, water analysis test results have shown contamination of the water during the storage in the clay pots. The use of water filters with storage capacity is the best solution to avoid recontamination of the water after filtration. Awareness regarding this issue is very important and must be increased. Except for the biosand filter, the uptake has been tremendous and the demand from villages outweighed the limited supply budgeted for. According to beneficiaries, their overall health and quality of life of communities has been improved and made them more productive. According to teachers, enrolment in schools was improved as children attended school regularly because incidences of illness decreased. Walking distances to water sources has been reduced as people were able to filter water from nearby sources without fear of infections. 5. CONCLUSIONS AND RECOMMENDATIONS Point of use water treatment is simple, inexpensive and should be replicated by other development partners. Even if some challenge remains regarding the sustainability of the filters, the point of use water treatment option seems to be better than other water treatments which are not sustainable or available. In fact, point of use water filters don’t need specific technical knowledge to operate and maintain and are inexpensive in a long term. ACF piloted 3 types of water filters. The Tiva water filters seems to be the most appropriate for Uganda. However, ACF and other partners should devise means of making the filters more easily accessible and available for community members who would wish to purchase them (e.g. to improve the supply chain by linking them to communities). It is important to conduct filter distribution hand in hand with other generic hygiene promotion messages and awareness creation with emphasis on safe water chain to avert contaminations. It is also important to train the beneficiaries before hand on O&M of the filters. Regular refresher trainings coupled with feedbacks from post monitoring surveys would improve the sustainability of the filters. Provision of safe drinking water at household level through POU water treatment – ACF Uganda (2012) Page 27 of 27