Press release

advertisement

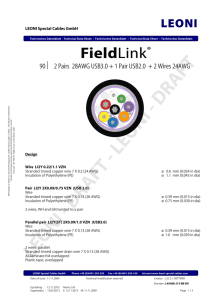

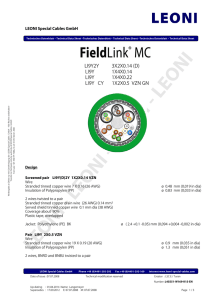

PRESS RELEASE Knowing what phase is Leoni determines electrical lengths of cables in its own lab Friesoythe, 1 December 2015 – The signal quality at the end of a transmission path is defined, among other factors, by the electrical parameters of a cable. In most cases the time offset due to a transmission path is not relevant and is therefore given generous tolerance, but when it is a matter of simultaneous signal transfer across various parallel cables, the ‘electrical length’ of an assembled cable is more important in certain applications than its mechanical length. In its laboratory, Leoni cuts its cables phase-matched to the customer’s request and takes this electrical length into account during assembly. The demand is normally for phase-matched lengths on cables two to three metres long, but, depending on the frequency, the mechanical length of cable is not limited. In a vacuum, signal waves spread at the speed of light (approx. 300,000 km/s). In the case of a cable, the signal spreads between the conductor(s) and the braid, i.e. normally inside the insulation. The relative dielectric constant of this insulation determines the signal speed. Minimal, production-related differences in the dielectric constant across various conductors are normally permitted within the framework of defined tolerances. The mechanical length of assembled cables usually has priority. But what is to be done when virtually no tolerances in the signal transfer across various assembled cables are allowed; as in the case, for example, of MRT coiled wiring or highly sensitive measurement cable systems? In such applications, propagation delay differences between several cables would have an immediate, negative effect on image quality or measurement readings. page 1 of 3 PRESS RELEASE Accuracy is wanted As a cables specialist, Leoni has an extensive range of electrical and mechanical testing methods. In its own laboratory, skilled members of staff can determine the electrical length of an assembled cable. The underlying parameters are calculated depending on the cable’s structure and prescribed frequency as part of the cable’s development and recorded in the design data. These parameters are measured with the help of vector network analysers and the mechanical length is adjusted to the electrical length. In one example, all cables are cut ‘too long’, assembled unilaterally and trimmed precisely down to a few degrees by means of measuring the reflected phase. Accuracy is also called for when it comes to the final fitting of the second connector. The length of insulation to be stripped for this purpose is taken into account in calculating the parameters in the design data and the prescribed measurements are adhered to exactly by Leoni staff when assembling the cable. (2.743 characters incl. blanks) Related illustration material can be downloaded next to this release at https://www.leoni-healthcare.com/en/news/details/knowing-what-phase-is/ About the Leoni Group Leoni is a global supplier of wires, optical fibers, cables and cable systems as well as related services for the automotive sector and further industries. Leoni develops and produces technically sophisticated products from single-core automotive cables through to complete wiring systems. Leoni’s product range also comprises wires and strands, standardised cables, special cables and cable system assemblies for various industrial markets. The group of companies, which is listed on the German MDAX, employs about 75,000 people in 31 countries and generated consolidated sales of EUR 4.1 billion in 2014. page 2 of 3 PRESS RELEASE Contact person for trade press Contact person for economic press Birte Wendeln Marketing Business Unit Healthcare LEONI Special Cables GmbH Phone +49 (0)4491-291-173 Fax +49 (0)4491-291-5173 E-Mail birte.wendeln@leoni.com Sven Schmidt Corporate Public & Media Relations LEONI AG Phone +49 (0)911-2023-467 Fax +49 (0)911-2023-231 E-Mail presse@leoni.com page 3 of 3