A cost effective technology to remove particulates from domestic

advertisement

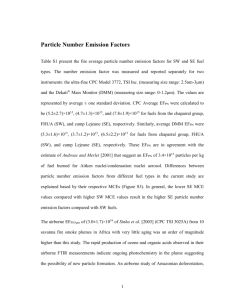

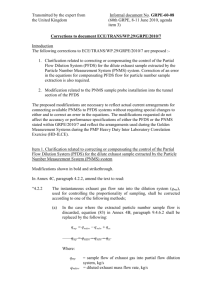

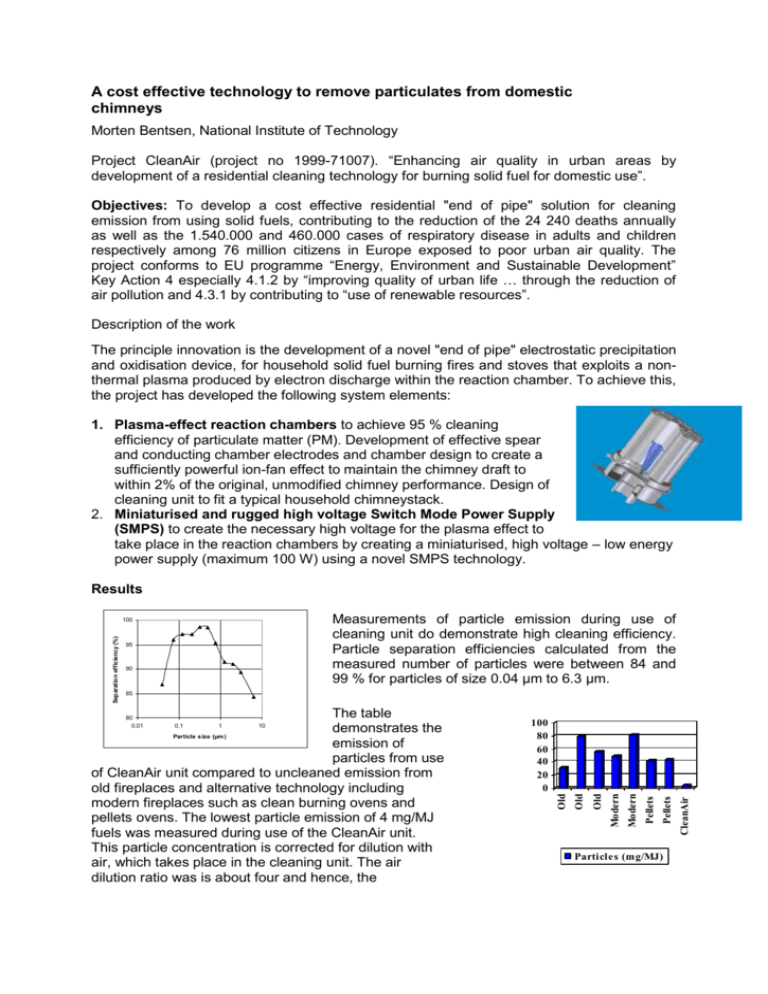

A cost effective technology to remove particulates from domestic chimneys Morten Bentsen, National Institute of Technology Project CleanAir (project no 1999-71007). “Enhancing air quality in urban areas by development of a residential cleaning technology for burning solid fuel for domestic use”. Objectives: To develop a cost effective residential "end of pipe" solution for cleaning emission from using solid fuels, contributing to the reduction of the 24 240 deaths annually as well as the 1.540.000 and 460.000 cases of respiratory disease in adults and children respectively among 76 million citizens in Europe exposed to poor urban air quality. The project conforms to EU programme “Energy, Environment and Sustainable Development” Key Action 4 especially 4.1.2 by “improving quality of urban life … through the reduction of air pollution and 4.3.1 by contributing to “use of renewable resources”. Description of the work The principle innovation is the development of a novel "end of pipe" electrostatic precipitation and oxidisation device, for household solid fuel burning fires and stoves that exploits a nonthermal plasma produced by electron discharge within the reaction chamber. To achieve this, the project has developed the following system elements: 1. Plasma-effect reaction chambers to achieve 95 % cleaning efficiency of particulate matter (PM). Development of effective spear and conducting chamber electrodes and chamber design to create a sufficiently powerful ion-fan effect to maintain the chimney draft to within 2% of the original, unmodified chimney performance. Design of cleaning unit to fit a typical household chimneystack. 2. Miniaturised and rugged high voltage Switch Mode Power Supply (SMPS) to create the necessary high voltage for the plasma effect to take place in the reaction chambers by creating a miniaturised, high voltage – low energy power supply (maximum 100 W) using a novel SMPS technology. Results Measurements of particle emission during use of cleaning unit do demonstrate high cleaning efficiency. Particle separation efficiencies calculated from the measured number of particles were between 84 and 99 % for particles of size 0.04 µm to 6.3 µm. 95 90 85 Particle s (mg/MJ) CleanAir Pellets Pellets 100 80 60 40 20 0 Modern 10 Old 1 Modern 0.1 Old The table demonstrates the Particle size (µm ) emission of particles from use of CleanAir unit compared to uncleaned emission from old fireplaces and alternative technology including modern fireplaces such as clean burning ovens and pellets ovens. The lowest particle emission of 4 mg/MJ fuels was measured during use of the CleanAir unit. This particle concentration is corrected for dilution with air, which takes place in the cleaning unit. The air dilution ratio was is about four and hence, the 80 0.01 Old Separation efficiency (%) 100 concentration of particles from the chimney would be four times lower if the air dilution would be included. Project manager: Applied Plasma Physics AS, P.O Box 584/Bedriftsveien 25, N-4035 Sandnes, Norway Industrial Partners include: SEREPS (France), VUKOV Extra AS (Slovakia), CSO Technik Ltd (UK), ShroederPlast AS (Denmark) and B+K Keramik u. Tonwaren GmbH (Germany). Primary research and development institution: Teknologisk Institutt (National Institute of Technology), P.O. box 2608/Akersveien 24c, St. Hanshaugen, N-0131 Oslo, Norway. Contributing research and development institution: Pera Technology, Pera Innovation Park, Melton Mowbray, LE13OPB, Leicestershire, United Kingdom, The project is financed in the EU Frame Programme 5 under the Co-operative Research Actions for Technology (CRAFT), project no 1999-71007 and has a total budget of 1.25 Million Euros, of which the EU contribution is 625.000 Euro.