An Introduction to Lean Six Sigma

advertisement

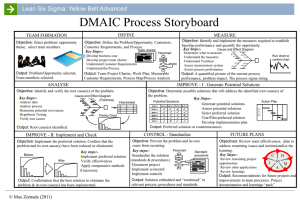

http://vimeo.com/24784020 An Introduction to Lean Six Sigma “We don’t know what we don’t know. We can’t act on what we don’t know. We won’t know until we search. We won’t search for what we don’t question. We don’t question what we don’t measure. Hence, we just don’t know.” Dr. Mikel Harry Process Improvement 1. Initial Perception of problem 2. Clarify Problem 3. Locate Point of Cause 4. Root Cause Analysis 5. Design Solutions 6. Measure Effectiveness 7. Standardize Lean Six Sigma Process Improvement • Lean Six Sigma Seeks to improve the quality of manufacturing and business process by: – identifying and removing the causes of defects (errors) and variation. – Identifying and removing sources of waste within the process – Focusing on outputs that are critical to customers Define Control Improve Measure Analyze Lean Six Sigma Process Improvement • LSS is a management philosophy that seeks to drive a quality culture change through a multi-level based program Level Training Green Belt LSS Methodology and basic tool set Black Belt Green Belt content plus advanced data analysis Master Black Belt Black belt content plus program management, leadership skills, some advanced tools Lean Six Sigma Timeline Guinness Brewery 1900 Ford Assembly Line Shewhart Introduces SPC 1930 Gilbreth, Inc. •Management Theory •Industrial Engineering Deming •14 Points •7 Deadly Diseases 1950 Toyota Production System Lean Six Sigma Timeline SPC TQM 1980 Just – in–Time Motorola Introduces Six Sigma 1990 Lean Mfg. AlliedSIgnal GE Adapt LSS to Business Processes 2000 Background on Lean • Lean comes out of the industrial engineering world • Taiichi Ohno – Toyota Production System. – 1940s-1950s company was on verge of bankruptcy – Dynamics of industry were changing – moving from mass production to more flexible, shorter, varied batch runs (people wanted more colors, different features, more models, etc). • Ohno was inspired by 3 observations on a trip to America – Henry Ford’s assembly line inspired the principle of flow (keep products moving because no value is added while it is sitting still) – The Indy 500 – Rapid Changeover – The American Grocery Store – led to the Pull system – material use signals when and how stock needs to be replenished Path To Lean Theory Waste is Deadly Application 1. Define Value – act on what is important to the customer 2. Identify Value Stream – understand what steps in the process add value and which don’t 3. Make it flow – keep the work moving at all times and eliminate waste that creates delay 4. Let customer pull -- Avoid making more or ordering more inputs for customer demand you don’t have 5. Pursue perfection -- there is no optimum level of performance Focus Flow Focused Assumptions Non-Value added steps exit Results Reduced cycle time Waste Defined Wastes Transport Inventory Motion Waiting Over-Production Over-Processing Defects Skills Healthcare Examples 1. 2. 3. 1. 2. 3. 1. 2. 1. 2. 3. 1. 2. 3. 4. 1. 2. 3. 1. 2. 3. 4. 5. 6. 1. 2. 3. 4. Moving patients from room to room Poor workplace layouts, for patient services Moving equipment in and out of procedure room or operating room Overstocked medications on units/floors or in pharmacy Physician orders building up to be entered Unnecessary instruments contained in operating kits Leaving patient rooms to: • Get supplies or record • Documents care provided Large reach/walk distance to complete a process step Idle equipment/people Early admissions for procedures later in the day Waiting for internal transport between departments Multiple signature requirements Extra copies of forms Multiple information systems entries Printing hard copy of report when digital is sufficient Asking the patient the same questions multiple times Unnecessary carbon copying Batch printing patient labels Hospital-acquired illness Wrong-site surgeries Medication errors Dealing with service complaints Illegible, handwritten information Collection of incorrect patient information Not using people’s mental, creative, and physical abilities Staff not involved in redesigning processes in their workplace Nurses and Doctors spending time locating equipment and supplies Staff rework due to system failures Lean Foundations • Standardized Work – people should analyze their work and define the way that best meets the needs of all stakeholders. – “The current one best way to safely complete an activity with the proper outcome and the highest quality, using the fewest possible resources” – Standardized not Identical – mindless conformity and the thoughtful setting of standards should not be confused – Written by those who do the work. • Level loading – smoothing the workflow and patient flow throughout the hospital. • Kaizen – continuous improvement Lean Methods • Kaizen Events (or SCORE events) – Planned and structured process that enables a small group of people to improve some aspect of their business in a quick, focused manner. • • • • • Select Clarify Organize Run Evaluate • 5S – this methodology reduces waste through improved workplace organization and visual management – Sort, Store, Shine, Standardize and Sustain • Kanban – a Japanese term that can be translated as “signal,” “card,” or “sign.” – Most often a physical signal (paper card of plastic bin), that indicates when it is time to order more, from whom, and in what quantity. Lean vs. Six Sigma • Lean tends to be used for shorter, less complex problems. Often time driven. Focus is on eliminating wasteful steps and practices. • Six Sigma is a bigger more analytical approach – often quality driven – it tends to have a statistical approach. Focus on optimizing the important steps – reducing defects. • Some argue Lean moves the mean, SixSigma moves the variance. But they are often used together and should not be viewed as having different objectives. – Waste elimination eliminates an opportunity to make a defect – Less rework means faster cycle times • Six Sigma training might be specialized to the “quality” department, but everyone in the organization should be trained in Lean VOC vs. VOP Sigma Capability Voice of Customer Defects per Million Opportunities % Yield 2 308,537 69.15% 3 66,807 93.32% 4 6,210 99.38% 5 233 99.98% 6 3.4 99.99966% Voice of Process The Voice of the Process is independent of the Voice of the Customer What’s good enough? 99% Good (3.8 Sigma) 99.99966% Good (6 Sigma) 20,000 lost articles of mail per hour (based on 2,000,000/hr) 7 articles lost per hour Unsafe drinking water for almost 15 minutes each day 1 unsafe minute every 7 months 5,000 incorrect surgical operations per week 1.7 incorrect operations per week 2 short or long landings daily at an airport with 200 flights/day 1 short or long landing every 5 years 2,000,000 wrong drug prescriptions each year 680 wrong prescriptions per year No electricity for almost 7 hours each month 1 hour without electricity every 34 years Goals of Lean Six Sigma LSL USL Defects LSL Defects Defects Customer Target Prevent Defects by Reducing Variation USL Customer Target LSL USL Customer Target Meet Customer Requirements Prevent Defects by Centering Process What Makes a Good Lean Six Sigma Project? • There is no known solution • The root cause is not known • The problem is complex and needs statistical analysis • The problem is part of a process • The process is repeatable • A defect can be defined • Project will take 3-6 months • There are data available The DMAIC Methodology • Define – describe the problem quantifiably and the underlying process to determine how performance will be measured. • Measure – use measures or metrics to understand performance and the improvement opportunity. • Analyze – identify the true root cause(s) of the underlying problem. • Improve – identify and test the best improvements that address the root causes. • Control – identify sustainment strategies that ensure process performance maintains the improved state. Define • Define Scope of the Problem – Document the Process – Collect and Translate the Voice of the Customer • Determine Project Objective and Benefits – Define Metrics and Defects – Establish Preliminary Baseline – Develop Problem & Objective Statements – Estimate Financial Benefit Define (continued) • Create Project Charter – Confirm Improvement Methodology – Define Project Roles and Responsibilities – Identify Risks – Establish Timeline – Managerial Buy-in • Focus here is on the problem Measure Measure what is measurable, and make measurable what is not so” – Galileo • Define “As Is” process – Value stream map/process flow diagram • Validate Measurement System for Outputs – Don’t assume your measurements are accurate – measuring system must accurately tell what is happening • Quantify Process Performance – Collect data (Y’s) – Examine process stability/capability analysis Analyze • Identify Potential Causes (X’s) • Investigate Significance of X’s – Collect data on x’s – Graphical/Quantitative analysis • • • • • Pareto Chart Fishbone Diagram (cause and effect) Chi Square Test Regression Analysis Failure Mode Effects Analysis • Identify Significant Causes to focus on (y=f(X)) – Evaluate the impact of x’s on y • Here you identify the critical factors of a “good” output and the root causes of defects or “bad” output. Improve • Generate Potential Solutions • Select & Test Solution • Develop Implementation Plan Control • Create Control & Monitoring Plan – Mistake proof the process – Determine the x’s to control and methods – Determine Y’s to monitor • Implement Full Scale Solution – Revise/develop process – Implement and evaluate solution • Finalize Transition – Develop transition plan – Handoff process to owner