Moses Jenkins Historic Scotland

advertisement

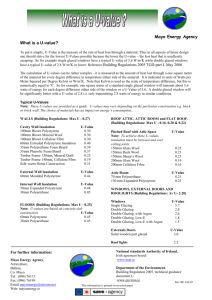

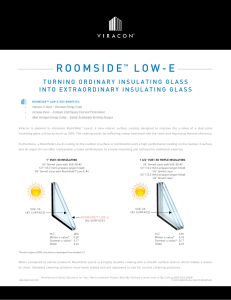

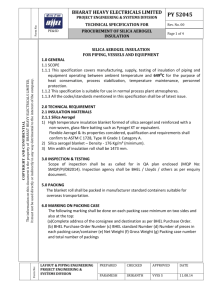

Improving Energy Efficiency in Traditional Buildings Moses Jenkins Technical Conservation Group Contents • Traditionally constructed buildings • Building elements: improvement options – Windows – Walls – Roofs – Floors – Doors Vapour movement in a traditionally built home. We can improve efficiency, but must be careful not to compromise this dynamic. Typical energy efficiency upgrade using expanded phenolic foam Traditional passive ventilation systems If we get it wrong.. Windows Draught Stripping Existing options – shutters & blinds – gave significant improvements uvalue 1.8 Secondary glazing Secondary glazing : U Value 1.7 secondary glazing manufactured by a joiner new sealed units within existing sashes, u-value 1.3 A new check is cut and the unit puttied in place Upgraded sashes awaiting rehanging Walls Historic Scotland research has examined 3 approaches to insulating mass masonry walls: •Putting insulation behind existing wall lining •Applying material directly to the masonry “on the hard” •Framing out and putting material between the timber Bonded polystyrene bead u-value 0.31 U-value improvement 68% 30mm Calcium silicate board applied directly to mass masonry Preparation for application of board (left) and the build up of the board and finishing layers (right), uvalue improvement from 2.1 to 1 10mm Aerogel blanket fixed directly to mass masonry Aerogel blanket particularly useful on curved walls, u-value improved from 1.3 to 0.6 Where previous linings have been lost or are irreparable more substantial interventions can be made Hemp board – u-value 0.21 Thermal improvement 78% 80mm Wood fibre board u value 0.19 Thermal improvement 81% Clay board (right) ready for application of clay plaster (left) 100mm cellulose fibre blown on the hard – U value 0.28 Thermal improvement 71% Aerogel insulated board – 50mm u value 0.31 Thermal improvement 65% An important element of the testing program is monitoring of moisture build up Moisture monitoring following the application of the insulation at Sword Street 90 80 Maximum Daily Relative Humidity [%] 70 60 50mm into Brick/Close Wall 50 Interface Close brick wall/Insulation 50mm into Stone/Exterior Wall 40 30 Interface Exterior Wall Stone/Insulation Room (RHmax) 20 10 0 May-2010 Jun-2010 Aug-2010 Sep-2010 Nov-2010 Jan-2011 Feb-2011 External Insulation Maybe not here… But what about here? Wood fibre insulation, Glasgow Negative visual impact of external insulation Floors Is it worth lifting this? Sheep’s wool pinned to under floor joists Hemp board between joists held in place with timber runners, u-value improvement 2.4 to 0.7 Breathable? Stone floors – can this be improved? Laying the insulated floor as a homogenous layer Concrete floors can be lifted and insulated lime concrete floor laid in its place Lime concrete layer being mixed, laid and flags laid on top Aerogel board placed over concrete floor, uvalue improvement 3.9 to 0.8 Lofts and roof spaces Should be 275mm thick whatever material used Vapour permeable options most appropriate such as sheep’s wool or wood fibre board Sheep’s wool between joists, u-value improvement 1.5 to 0.3 (wood fibre board u-value 0.2) Insulating behind existing roof linings in inhabited loft space, u-value improvement 1.6 to 0.8 Blowing bonded bead into a mansard dormer cheek insulation behind the plasterboard Insulating between rafters using hemp / wool material Doors Door panels can be insulated to reduce heat loss, u-value improvement 3.9 to 0.8 Conclusion • Vapour permeability and ventilation should be maintained throughout any energy upgrade work • All elements of traditionally constructed buildings can be made more thermally efficient by the use of a range of materials and techniques • It is vital that this work is carried out sensitively to both the aesthetic and performance of the building and ventilation vital to More details of all research available at Historic Scotland website: www.historic-scotland.gov.uk/technicalpapers I can be contacted at moses.jenkins@scotland.gsi.gov.uk Which one has the best chance of still being useful in 100 years?