Diapositive 1

advertisement

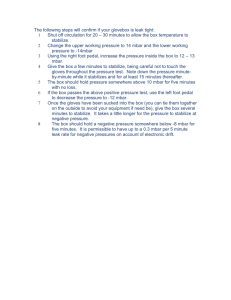

NEW OIL REGENERATION PLANT WITH REACTIVATED FULLER’S EARTH Oil regeneration with reactivated Fuller’s Earth Applications: Reduction in oil acidity from 0.4 mg Koh/gm to 0.03 mg Koh/gm. Advantages: The same quantity of Fuller’s earth can be used >300 times due to the unique reactivation process. Benefit of the oil regeneration process compared to conventional purification system. Remove contaminants such as acids, sludge, anilines and decaying products. -Improve color, oxidation stability, Interfacial tension and power factor -Extend the oil life-time cycle -Extend more significantly the life-time cycle of power transformers (with regular regeneration treatment) Strengths & Weaknesses of the different solutions to solve acidity Strengths Weaknesses Change the oil to a new or reclaimed oil No specific equipment required: (oil pump, oil treatment plant, tank,..) No graduate people required Power shutdown Subject to new oil price $$$$$ or difficult to find reclaimed oil. Old oil has to be disposal or resale for third applications at very low price. Short term solutions, no clean out of the transformer. Several people requested Regenerate the oil No power shutdown during regeneration process Short pay back return No oil to eliminate No subject to oil price fluctuation or shortage Clean out the transformer Specific equipment required Not a lot of equipment available Graduate people required Main differences between both solutions to regenerate dielectric oil Regeneration with disposable Fuller’s earth Regeneration with reactivated Fuller’s earth Oil losses 6% 0,4% Fuller’s earth losses 100% 0,01% by reactivation (limit 70% before replacement) Tasks Replacement of Fuller’s earth at saturation Replacement almost once a year Workforce Several people to handle operations One people for normal operations Few people for Fuller’s Earth replacement. Oil test results (general) TEST DESCRIPTION METHOD UNIT INITIAL OIL CONDITION ERP 5000 SINGLE PASS QUALITY 8 0,01 <15 >40 Brown/Cloudy Clear Light Yellow GAS CONTENT GC %v/v IFT ASTM Dynes/cm COLOR APPEARANCE -- Visual TAN DELTA (90°C) IEC 247 -- <0,01 <0,005 OXIDATION STABILITY IEC 74 164 HRS -- Depleted Restored MOISTURE IEC 733 ppm <200 5 BREAKDOWN VOLT IEC 156 kV <30 >75 ACIDITY IEC 296 mgKOH/gm 0,4 <0,03 ARRAS MAXEI Product range MAS 5000 ERP 6 Columns MAS 5000 ERP 9 Columns MAS 5000 ERP 12 Columns MAS 5000 ERP Dual bank of columns Flow rate 5000 l/h 5000 l/h 5000 l/h 5000 l/h Regenerated oil 2400 l/day 3600 l/day 4800 l/day Capacity x 2 Filtration 1µm absolute 1µm absolute 1µm absolute 1µm absolute Treatment heating power 80 k W 80 k W 80 k W 80 kW Reactivation heating power 36 kW 54 kW 72 kW 3 kW per column Total heating power 116 kW 134 kW 152 kW Reactivation+ Treatment heating power Limit vacuum closed suction 0,5 mbar 0,5 mbar 0,5 mbar 0,5 mbar Vacuum in treatment (mbar) 0,5 to 5 0,5 to 5 0,5 to 5 0,5 to 5 Fullers earth quantity 600 kgs 900 kgs 1200 kgs Nbre columns x 100 kgs General layout Presentation SKID SEMI TRAILER Container design for easy access and maintenance SEA CONTAINER (20’ OR 40’)°