EHSO online WHMIS Training Presentation

University of Manitoba

WHMIS

Revised November 2011

1

WHMIS Stands for…

W

orkplace

H

azardous

M

aterials

I

nformation

S

ystem

2

WHMIS is…

The Workplace Hazardous Materials Information System is a

Canada-wide system designed to give employers and workers information about hazardous materials used in the workplace.

WHMIS standards are coordinated between both Federal and

Provincial governments.

Manitoba Workplace Safety and Health Act and Regulations sets the WHMIS requirements.

3

WHMIS has 3 Main Parts

Labels – provide information about the hazards of the product

Material Safety Data Sheets (MSDS) – provide further detailed information

Education – how to use the information provided

4

The GOAL is…

Identify 6 Classes of Controlled Products

Understand the Main Hazards associated with each class

Recognize and understand the two types of WHMIS labels

Understand how to use Material Safety Data Sheets

A Controlled Product is…

A Controlled Product is any substance or material which meets any of the criteria for inclusion in one or more of the six WHMIS Hazard Classes as defined in the Federal

Controlled Product Regulation.

Under WHMIS , there is no comprehensive list of controlled products but only a list of hazard criteria.

6

WHMIS Does Not Apply

When WHMIS does not apply there may be another Act or regulation that does.

WHMIS does not apply to controlled products that are:

Wood or a product made of wood

Tobacco or a product made of tobacco

A manufactured item that will not release chemicals

Products transported under the Transportation of

Dangerous Goods Act – for more information regarding TDG: http://umanitoba.ca/admin/human_resources/ehso/emanagement/tdg.html

WHMIS Does Not Apply

WHMIS does not apply to products covered by:

Explosives Act

Food and Drugs Act

Pest Control Products Act

Certain products in the Hazardous Products Act

Nuclear Safety and Control Act

WHMIS Applies for

WHMIS labels and MSDS are still required for:

Mixtures of radioactive nuclide(s) and a non-radioactive carrier material where:

The carrier material is greater than 1.0 ml / 1 g

The carrier material poses a carcinogenic, toxic, reactive, or infectious hazard

For more information regarding Radiation Safety: http://umanitoba.ca/admin/human_resources/ehso/rad_safety/index.html

Hazard Classes & Symbols

There are 6 Hazard Classes

Hazard Classes & Symbols

Class A : Compressed Gases

Risks

Physical hazard (120kg)

Explosive hazard

Content hazard

Examples

CO

2 cylinders

N

2 cylinders

O

2 cylinders

acetylene

Hazard Classes & Symbols

Class A : Compressed Gases

Handling and Use

Secure cylinder upright with valve cap on when not in use

Use gas specific regulator

Test connections for leaks

Avoid heat & ignition sources

Transport using specialized cart

Store in cool ventilated area

Hazard Classes & Symbols

Class A : Liquid N

2

& Dry Ice

Risks

Frostbite

Samples may explode

Asphyxiation

Handling and Use

Avoid skin contact

Wear insulated gloves and eye protection

Store in a well ventilated room

Transport securely to prevent accidental spillage

Store Liquid N

2 in a vented dewar

Hazard Classes & Symbols

Class B : Flammable & Combustible

Six Subdivisions

1. Flammable gas

2. Flammable liquid

3. Combustible liquid

4. Flammable solid

5. Flammable aerosol

6. Reactive flammable material

Hazard Classes & Symbols

Class B : Flammable & Combustible

Risks

Fire hazard – will burn if ignited

Could ignite spontaneously

Could ignite upon mixing with water or other chemicals

Many are poisonous

Hazard Classes & Symbols

Class B : Flammable & Combustible

Examples

1. Flammable gas – hydrogen, methane

2. Flammable liquid [flash pt <37.8C] – gasoline, ether

3. Combustible liquid [flash pt >37.8C] – kerosene, varsol

4. Flammable solid – magnesium metal, aluminum dust

5. Flammable aerosol – propane, butane, isobutane

6. Reactive flammable material – phosphorus, sodium metal

Hazard Classes & Symbols

Class B : Flammable & Combustible

Handling and Use

Avoid contact with flames, heat, & ignition sources

Cap tightly for storage, vapours are flammable

Avoid inhalation and skin contact

Ground and bond when dispensing from 25L container

Store in flammable storage cabinets if in excess of 50L

Transport separate from oxidizing materials

Transport securely using secondary containment

Hazard Classes & Symbols

Class C : Oxidizing Material

Risks

Increase fire and explosion hazard

May cause combustibles to explode or react violently

May burn skin and eyes on contact

Most are corrosive and poisonous

Examples

Peroxides

Nitrates

Persulfates

Hypochlorites

(bleach)

Hazard Classes & Symbols

Class C : Oxidizing Material

Handling and Use

Wear the recommended protective equipment and clothing

Store away from sources of heat and ignition

Many oxidizers are shock sensitive, handle carefully

Store and transport separately from flammables and organics

Store in non-corroding containers

Transport securely

Hazard Classes & Symbols

Class D : Poisonous and Infectious

Division 1 – Materials Causing Immediate and Serious Toxic Effects (acute)

Division 2 – Materials Causing Other Toxic

Effects (chronic, delayed)

Division 3 – Biohazardous Infectious Material

20

Hazard Classes & Symbols

Class D : Poisonous and Infectious

Division 1

Risks

Small quantities may be harmful or lethal

May be toxic not only if ingested but also if inhaled or absorbed through skin or eyes

Many acute toxic compounds act as carcinogens at lower levels

Examples

Carbon monoxide

All halogens

Cyanides

Hazard Classes & Symbols

Class D : Poisonous and Infectious

Division 2

Risks

Materials which have harmful effects after repeated exposures or over long periods of time

Damage could include:

Permanent injury or death

Birth defects

Cancer

Organ damage

Sensitization and allergies

Examples

Asbestos

Formaldehyde, benzene

Ammonia

Hazard Classes & Symbols

Class D : Poisonous and Infectious

Division 3

Risks

Infectious materials which may cause disease resulting in illness or death

Examples

Blood, tissue, and body fluids

Tissue culture

Experimental cultures

Hazard Classes & Symbols

Class D : Poisonous and Infectious

Handling and Use

Wear protective clothing to avoid all exposures: skin, inhalation, ingestion, and injection

Work in a fume hood or BSC

Avoid creating dust, vapours, and aerosols

Obtain appropriate immunizations

Handle exterior containers as though it is contaminated

Store and transport securely to prevent accidental spillage

Hazard Classes & Symbols

Class E : Corrosive Material

Risks

Will burn human tissue including skin, eyes, nose mouth, throat & lungs

Will corrode many lab related materials particularly metals

Fumes may damage the environment

Examples

Strong acids & bases

Hydrogen fluoride

Hydrogen chloride

Hazard Classes & Symbols

Class E : Corrosive Material

Handling and Use

Wear appropriate protective clothing

When possible work in the fume hood

Open containers slowly

When diluting acids, always add acid to water

Store in non-corroding containers, on non-corroding trays

(secondary containers )

Store away from combustibles, organics, and sources of heat and ignition

Transport separate from flammables

Transport securely using secondary containment

Hazard Classes & Symbols

Class F : Dangerously Reactive

Risks

May be unstable or vigorously polymerize

May react with water to release a toxic or flammable gas

May self-react when shocked or heated

Highly reactive with incompatible materials

May burn eyes and skin on contact

Examples

Ether

Acrylates

1,3-butadiene

Metal azides

Hazard Classes & Symbols

Class F : Dangerously Reactive

Handling and Use

Follow MSDS recommendations for use and storage

Wear protective clothing, especially eye protection

Open slowly and carefully & use in fume hood

Ensure lab equipment is clean and free of impurities

Store away from incompatible chemicals

Keep away from heat and ignition sources; avoid sudden temperature changes

May require inhibitors to prevent reaction during storage

Examine storage containers frequently

Store & transport securely

Label Types

Supplier Labels

Workplace Labels

U of M Waste Tag

29

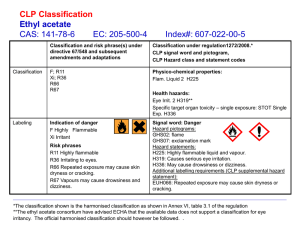

Labels

Supplier Labels

The following must be included on a supplier label:

Product Name

WHMIS Symbols

Risk Phrases

Precautionary Measures

First Aid Measures

MSDS Reference

Supplier Name

All information must be within a hatched border

Labels

Laboratory Supply House - Supplier Label

3) Symbol

31

Labels

Workplace Labels

The following must be included on a workplace label:

Product Name

Safe Handling Instructions

MSDS Reference

Methanol

Flammable, poisonous, harmful vapor

Keep away from heat, sparks, flames

Avoid contact with eyes and skin

Labels

Workplace Labels

x x x x x

Methanol

Must be present on:

Products decanted or transferred from an original container

Product where original label is lost or becomes illegible

Products produced and used at the workplace

You can print your own WHMIS workplace labels

Labels

Workplace Labels – Hazardous Waste

The following must be included on a hazardous waste label:

Product Name

Concentration

Hazard

Labels

Workplace Labels – Hazardous Waste

Waste Tags must:

Be present on containers that do not have a correct supplier label

Must list any chemical over 1% or any quantity if it poses a significant hazard

Use only chemical names (no trade names, abbreviations, or formulas)

Print your own hazardous waste labels

Material Safety Data Sheets (MSDS)

Provides detailed information on the hazards of a controlled product

An important element for developing safe work procedures and control measures

Must be provided by the supplier, or If you have created a product, you must prepare a MSDS

Risk Group 2 and higher biological agents also require a MSDS or a Pathogen Safety Data Sheet (PSDS)

Must be replaced every 3 years

All MSDS must be kept for 30 years

36

MSDS

Information Provided

Product Information

This section identifies product name, manufacturer and suppliers names, addresses, and emergency phone numbers, and the intended use of the product.

Hazardous Ingredients

This section lists All potentially hazardous ingredients, with the approximate amount (percent), and toxicity data for the individual ingredients. Information regarding the LD50 and LC50 (the amount of a chemical that is expected to kill 50% of a test animal population within a specified time) will also be given. The lower the value the greater the poisoning potential.

MSDS

Information Provided

Physical Data

Provides information on the physical and chemical properties such as odour, boiling point, and vapour density.

Fire or Explosion Hazard Data

Provides the conditions under which the product may catch fire or explode, as well as information for developing strategies and procedures to deal with fire and explosion hazards.

First Aid Measures

Lists the procedures for emergency first aid.

MSDS

Information Provided

Reactivity Data

Provides information regarding stability, self-reactivity, hazardous decomposition products, and conditions to avoid when using the product.

Toxicological Properties

Identifies how the substance can enter the body and the possible health effects from short term (acute) exposures such as irritation, sensitization; and long-term (chronic) such as liver or kidney damage, sensitization, cancer, or reproductive effects. Known exposure limits will also be given.

MSDS

Information Provided

Preventative Measures

Provides preventive measures you can take to protect yourself from exposure including: extra ventilation, personal protective equipment

(PPE), safe use, handling, storage, disposal, transport, and spill control.

Preparation information

Indicated who was responsible for preparation and date of preparation of MSDS. It is 3 years from this date when the MSDS needs to be renewed.

Information may be labeled as Trade Secret if a claim has been filed.

The information is released to medical professionals in case of emergency.

MSDS

Example

MSDS

Location, Location, Location

Hazardous Waste Disposal Procedures

The University has well established guidelines and procedures to deal with hazardous waste disposal

EHSO provides hazardous waste disposal services at no charge to the University faculties and departments

Incorporate waste disposal into lab procedures or experiments

NO disposal of Hazardous Waste is permitted down the drain or regular trash can

Remember that your end point is someone’s starting point

Refer to the EHSO webpage for details

Spill Clean-up

Chemical, Radiological, or Biological

If a spill occurs that poses an immediate risk to people, or if someone is injured – it is an EMERGENCY – call 555

Minor spills should be cleaned up by trained staff

Spills must never be cleaned up by untrained staff

Under no circumstance shall caretakers be instructed to clean up any lab spills

The best time to learn about and practice cleaning up a spill is before it happens – read the MSDS

EHSO is also available to assist with the cleanup of “non-emergency” spills beyond the capabilities of available staff

Information on spills cleanup can be found on the EHSO website

Chemical Storage

General Chemical Organization

Organize by compatibility not alphabetically

Separate each compatible group

In separate cabinets or on separate shelves

Or in secondary containers in same cabinet or shelf

Make sure all containers are properly closed

Containers must be labeled and tightly capped

Chemical Storage

General Chemical Organization

Flammables

Bases

Oxidizers

Acids

Store in flammable storage cabinets

Store separately

Store separately

Store in corrosive resistant acid cabinet

EXCEPT: chromic, nitric, and perchloric acids which should be stored separately

Glacial acetic acid should be stored as a flammable

Chemical Storage

Potentially Explosive Chemicals

Picric Acid and Nitro Compounds

Dry picric acid may explode if subjected to heat, shock, or friction

(opening the lid)

Picric acid must be stored under wet.

Some nitro compounds may have similar requirements

Peroxide Forming Compounds

Example ethers, dioxanes, sodium amide

Peroxide formation may be initiated by light or air

Peroxides are prone to explosive decomposition when subjected to heat, shock, or friction (opening the lid)

Evaluate the conditions of these chemicals regularly

Refer to MSDS for storage and handling requirements

Chemical Storage

General Chemical Segregation

Do Not Store:

Oxidizers

Alkali metals

Acetic Acid

Acetone

Hypochlorites

Chlorine

Cyanides (Alkaline)

Potassium chlorate

Chlorates (ClO

3

)

Hydrogen Sulphide

H

2

O

2

Chromic Acid

With:

Flammables

Water, CO

2

, CO, or CCl

4

Chromic, nitric or perchloric acid, peroxides, permanganates, or hydroxides i.e. KOH

Concentrated sulphuric or nitric acids

Acids

Ammonia, acetylene, butadiene, benzene, petroleum derivatives, or sodium carbides

Acids

Acids

Ammonium salts, acids, metal powders, sulphur, or carbon

Nitric acid

Flammables, Cu, Cr, Fe, or respective salts

Acetic acid, alcohol, naphthalene, glycerine, or other flammable liquids

Annhydrous Ammonia Halogens, Hg, HF, or CaClO

4

Acids (conc.) Bases (conc.)

Chemical Storage

General Chemical Organization & Segregation

Do Not:

Do not place heavy materials, liquid chemicals, and large containers above eye level

Do not store chemicals on the floor

Do not store items in fume hoods

Do not expose stored chemicals to direct heat or sunlight

Chemical Inventory

U of M Chemical Inventory Database

As part of the Manitoba

Workplace Safety and Health Act and Regulations, an inventory of chemicals is required at the

University.

The University provides the EHS

Assistant database. It can be accessed from the EHSO website.

53

Your supervisor or a designate is responsible for work‐site‐specific education that includes:

Hazard information for the controlled products used at your work site

Safe use, storage and handling of specific controlled products used at your work site

Dealing with fugitive emissions and emergencies at your work site

MSDS location