- ePrints Soton

advertisement

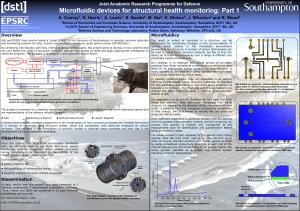

Joint Academic Research Programme for Defence Microfluidic devices for structural health monitoring: Part 2 A. 1 Cranny , N. 1 Harris , A. 1 Lewis , 2 Neodo , S. M. 2 Nie , K. 3 Stokes , J. 2 Wharton and R. 2 Wood 1School of Electronics and Computer Science, University of Southampton, Southampton, Hampshire, SO17 1BJ, UK 2nCATS, School of Engineering Sciences, University of Southampton, Southampton, Hampshire, SO17 1BJ, UK 3Defence Science and Technology Laboratory, Porton Down, Salisbury, Wiltshire, SP4 0JQ, UK Sensors Corrosion Database Research effort has focused on electrochemical sensors with two different technologies being investigated. These will be integrated into custom holders positioned within the measurement zone of the microfluidic ion separator. ● We have established a capillary electrophoresis methodology to simultaneously detect up to six metal cations that 1. Screen-printed platinum and gold electrodes: ● Good response to Cu2+, Cu+, Fe3+, Fe2+ ● Cheap, mass-producible ● Multitude of electrode geometries available ● Generally printed on alumina substrates ● Can be directly printed on to some stainless steels ● By applying this methodology to crevice solution samples, a crevice corrosion solution chemistry database is being developed for a variety of alloys used in marine environments, providing: 800 700 600 0.5 mM 1.1 mM 1.8 mM 2.5 mM 1 : Fe 3 e 3.4 mM 5.4 mM 2 : Cu 2 Cl 7.0 mM 2 3 : CuCl 10.0 mM 4 : Fe e e e - In-depth understanding of the evolution of localised corrosion solution chemistry; 3 CuCl Cu Fe 2 2 2 Cl - Identification of key corrosion makers for corrosion monitoring. ● The evolution of corrosion solution chemistry is being correlated with the material degradation process, thus 3 establishing a library of characteristic ‘fingerprints’ that categorise the state of corrosion and define the timing for maintenance or mitigation actions. 400 300 3 100 Insulation Fe 500 200 Open window 2 2 Crevice Forming Test Structures 4 1 0 -900 -700 -500 1. Block structure -300 -100 100 300 500 700 900 E vs Ag/AgCl (3.5M KCl), mV AgPd layer Left: Schematic of single screen-printed electrode. Above: Oxidation of equal concentrations of Cu2+ and Fe3+ at a platinum screen-printed electrode in 3.5% NaCl using differential pulse voltammetry. Substrate Gold or platinum Solderable end contact . 2. Boron-doped diamond (BDD) electrodes: Access holes for extracting samples BDD electrodes are widely used in electroanalysis due to their outstanding properties. Their chemical-physical characteristics result in a sensitive response to a number of chemical species. Boron atom substituted at vacancy in carbon lattice ● Direct determination of Ni2+ in a reagentless process 0.90 0.00 0.80 -0.05 0.70 2 -0.15 -0.20 1 mM -0.1 5 mM 10 mM -0.2 -0.25 100 mM -0.3 0 50 Conc / mM 100 35 uM 40 uM 45 uM 50 uM 55 uM 60 uM 65 uM 70 uM 75 uM 0.25 0.50 0.20 0.40 0.30 Electrolyte level Silicone seal around 3 sides Polyurethane base 1000 0 0 50 100 150 200 250 300 350 400 2. Cortest structure A large number of identical assemblies are immersed in a corrosive electrolyte solution. At predefined times, single samples are removed and frozen prior to disassembly. Upon thawing, residual solutions are collected from various locations of the corroded metal surface for CE analysis. Metal sample PMMA crevice former 0.15 1 0.10 Ni 2 e Ni Isometric view 3 2 3 0.00 0.10 Titanium bolt, nut and washers 20 30 40 50 60 70 80 Conc / uM 4 0.00 -700 -500 -300 -100 100 300 500 700 900 450 Evolving metal ion concentration profiles in the crevice of a sample of nickel-aluminium bronze (NAB) as it corrodes in 3.5% NaCl over a period in excess of 1 year. Sectional view 0.05 0.20 150 mM 150 30 uM 0.60 30 mM 50 mM -0.30 -900 j / mA cm-2 0.0 j Peak / mA cm -2 j / mA cm-2 -0.10 j Peak / mA cm -2 Fe 1500 Crevice Isometric view Crystalline structure of boron-doped diamond electrode. Nickel ion Immersion time in 3.5% NaCl (Days) ● Good response to Cu2+, Cu+, Fe3+ and Fe2+ e Aluminium ion 500 Metal sample Based on our research, we have observed: 3 Ferric ion 2000 Allows direct sampling of crevice solution at different depths from crevice entrance, which are then analysed using capillary electrophoresis. Nylon bolts Fe Cupric ion Concentration (ppm) Current, uA (304, 316, 430, 430S17) are representative of corrosion products from a wide variety of structural metals and alloys. 0 200 400 600 800 1000 1200 1400 E vs Ag/AgCl (3.5M KCl), mV E vs Ag/AgCl (3.5M KCl), mV Reduction of Fe3+ to Fe2+ in background of 3.5% NaCl using differential pulse voltammetry. Oxidation of Ni2+ to Ni3+ in background of 3.5% NaCl using differential pulse voltammetry. Images of cast lean duplex stainless steel CLD 21 with Cortest crevice corrosion testing in 3.5% NaCl for 28 days. (1) outside crevice (2) trench (3) crevice, no attack (4) crevice, severe attack. Sectional view