Networks

advertisement

ELECTRICAL, THERMAL AND MECHANICAL

PROPERTIES OF RANDOM MIXTURES

MATERIALS RESEARCH CENTRE

DEPARTMENT OF MECHANICAL ENGINEERING

UNIVERSITY OF BATH, UK

• ELECTRICAL PROPERTIES –

POWER LAW DISPERSIONS AND

UNIVERSAL DIELECTRIC

RESPONSE

• THERMAL PROPERTIES

• MECHANICAL PROPERTIES

POWER LAW DISPERSIONS

Log

CONDUCTORS

(w)= dc + Awn

Slope n

0<n<1

Log frequency

Log ’

Slope (n-1)

0<n<1

Log frequency

EXAMPLES:

Al2O3-TiO2

10

-2

10

(w) wn

(0)

-3

10

700ºC

10

10

10

10

10

-4

-5

-6

10

10

10

10

-7

200ºC

10

-8

10

0

10

1

10

2

10

3

10

4

Frequency (Hz)

10

5

-4

230C

Conductivity (Siemens/m)

Conductivity (Siemens/m)

10

Yttria doped ZrO2

10

6

10

-5

200C

-6

170C

-7

140C

-8

110C

-9

80C

-10

50C

-11

10

-1

10

0

10

1

10

2

10

3

10

Frequency (Hz)

4

10

5

10

6

ANOMALOUS POWER LAW DISPERSIONS

HAVE BEEN FOUND IN

ALL CLASSES OF MATERIALS

SINGLE CRYSTALS

POLYCRYSTALLINE MATERIALS

POLYMERS

GLASSES

CERAMICS AND COMPOSITES

CONCRETE & CEMENTS

IONIC & ELECTRONIC CONDUCTORS

ANOMALOUS POWER LAW DISPERSIONS

ARE

UBIQUITOUS

“THE UNIVERSAL DIELECTRIC RESPONSE”

A SATISFACTORY EXPLANATION MUST

ACCOUNT

FOR THIS UBIQUITY

THEORETICAL INTERPRETATIONS

1-DISTRIBUTIONS OF RELAXATION TIMES

2-EXOTIC MANY-BODY RELAXATION MODELS

STRETCHED EXPONENTIALS

POWER LAW RELAXATION

3-ELECTRICAL NETWORK MODELS

THE ANOMALOUS POWER LAW DISPERSIONS

ARE NOT CAUSED BY

UNCONVENTIONAL ATOMIC

LEVEL RELAXATION EFFECTS

THEY ARE MERELY THE AC ELECTRICAL

CHARACTERISTICS OF THE

ELECTRICAL NETWORKS

FORMED IN

SAMPLE MICROSTRUCTURE

Microstructure of a real technical ceramic.

Alumina 3%Titanium oxide

RTiO2

CAl2O3

10m

EXAMPLE OF AN ELECTRICAL NETWORK OF

RANDOMLY POSITIONED RESISTORS AND

CAPACITORS CHARACTERISED USING CIRCUIT

SIMULATION SOFTWARE.

Conductivity (S)

Simulations of (a) ac conductivity and (b) capacitance of a 2D

square network containing 512 randomly positioned components,

60% 1k resistors and 40% 1nF capacitors.

POWER LAW

FREQUENCY

DEPENDENCES

1E-3

Network conductivity

slope 0.4

(a) n=capacitor proportion

1E-4

= 0.4

1E-8

1E-5

Network capacitance (F)

(b)

1E-9

1E-6

slope -0.6

n-1 = -0.6

1E-7

2

10

3

10

4

10

Frequency (Hz)

5

10

6

10

Ac conductivity of 256 2D networks randomly

filled with 512 components 60% 1 k resistors

& 40% 1 nF capacitors

PERCOLATION

DETERMINED DC

CONDUCTIVITY

POWER LAW (w) wn

NETWORK INDEPENDENT

PROPERTY

Network type

(%R:%C)

Power law fit, n

60:40

0.399

50:50

0.487

40:60

0.594

NETWORK CAPACITANCE

POWER LAW DECAY

(w) wn-1

ORIGIN OF THE POWER LAW

RC NETWORK CONDUCTIVITY AND PERMITTIVITY

ARE RELATED TO COMPONENT VALUES BY THE

LOGARITHMIC MIXING RULE – LICHTENECKER’S RULE:

*

Network

complex

conductivity

n(1/R)1-n

=(iwC)

NET

Capacitor

conductivity

(admittance)

Capacitor

proportion

Resistor

proportion

Resistor

conductivity

Re. *NET = Cn(1/R)1-n cos(n/2) wn

AC

Conductivity

NETWORK CAPACITANCE

Cnet = Im. *net /iw

Cnet= Cn (1/R)1-n sin(n/2) wn-1

Real Heterogeneous Materials

system = (ins0)n(cond)1-n cos(n/2) wn

system =(ins0)n(cond)1-n sin(n/2) wn-1

FREQUENCY RANGE OF POWER LAW

10

Normalised Conductivity

1

Resistor

conductivity = R-1

0.1

60% R, 40% C

frequency independent

0.01

1E-3

1

10

100

1000

10000

100000 1000000

1E7

1E8

1E9

Frequency (Hz)

10

1

frequency dependent

0.1

-1

AC Conductance (ohm )

Capacitor ac

conductivity = wC

0.01

-1

R

1E-3

1E-4

CHARACTERISTIC

FREQUENCY

R-1 = wC

1E-5

wC

1E-6

1E-7

1E-8

1E-9

1

10

100

1000

10000

100000 1000000

Frequency (Hz)

1E7

1E8

1E9

EXPERIMENTAL INVESTIGATION

MATERIALS REQUIREMENTS:

•TWO-PHASE CONDUCTOR-INSULATOR SYSTEM

WITH A RANDOM MICROSTRUCTURE

•CONDUCTIVITIES OF THE TWO PHASES SIMILAR,

IN THE RADIO FREQUENCY RANGE

w0

<107

8.854x10-12

<2000

10-1 Sm-1 (metals 107 Sm-1)

SYSTEM CHOSEN

INSULATING PHASE: 22% POROUS PZT CERAMIC

1500

CONDUCTING PHASE:

WATER

10-1 Sm-1

= w0 at <1MHz

Conductivity Sm

-1

COMPONENT CHARCTERISTICS

1.0

(b)

Water conductivity

0.1

1000

PZT rel. permittivity

100

2

10

3

10

4

10

5

10

6

10

Frequency (Hz)

BOTH PHASES RELATIVELY FREQUENCY INDEPENDENT

Rel. Permittivity

(a)

Conductivity Sm

-1

SYSTEM CHARACTERISTICS

0.1

PZT +water conductivity

(a)

0.01

system = DC +(PZT0)n(water)1-n cos(n/2) wn

DC

10000

slope -0.22

1000

2

10

3

10

4

10

Frequency (Hz)

system =(PZT0)n(water)1-n sin(n/2) wn-1

5

10

Rel. Permittivity

PZT + water

rel. permittivity

(b)

6

10

PZT = 1500

water = 0.135 Sm-1

n = 0.78 (PZT %density)

EFFECT OF REDUCING

CONDUCTIVITY

w0 at <0.1MHz

Conductivity (S/m)

0.01

water/methanol conductivity

Characteristic

frequency

1E-3

1E-4

100

1000

10000

100000

1000000

1E7

Frequency (Hz)

10000

Relative Permittivity

78% dense PZT

+

Methanol 10% water

Conductivity 3.6x10-3 S/m

0.1

slope -0.22

1000

100

1000

10000

100000

Frequency (Hz)

1000000

1E7

EFFECT OF SAMPLE POROSITY ON

RELATIVE PERMITTIVITY

36%

10000

Relative Permittivity

28%

16%

22%

1000

1000

10000

100000

Frequency (Hz)

1000000

1E7

(b) water conductivity

0.1

x20

(c) PZT + water conductivity

0.01

PZT + water

(d)

rel. permittivity

10000

slope -0.22

1000

(a) PZT rel. permittivity

2

10

3

10

4

10

Frequency (Hz)

5

10

6

10

Rel. Permittivity

Conductivity (Siemens/m)

COMPARISON OF SYSTEM AND COMPONENT

CHARACTERISTICS

TEST OF OTHER MATERIALS

(estimation of characteristic frequency from component data)

~ 20DC

[Archie’s Law]

At the characteristic frequency = w0

fch = /20 ~ 20DC/20

TEST OF OTHER MATERIAL SYSTEMS

estimation of characteristic frequency from experimental data

AC=(0)n()1-n cos(n/2) wn

At the characteristic frequency where

w0=

AC=cos(n/2)~ /2

Conduction phase conductivity ~20x DC

Thus at the characteristic frequency, fch AC ~10x DC

Log

10x DC

f10DC

Log frequency

Theoretical

fch ~ 20DC/20

Experimental fch ~ f10DC [AC ~10x DC]

TEST CORRELATION

Saltwater

high

log 20 (0)/2 o Hz [theortl.]

10

Whitestone-saltwater

Carbon blackthermoset

8

LiCl.H 2O (-114°C)

Polypyrole-polyoxyphenylene

Hydroge l

Whitestone

low

Water-PZT

6

Na -alumina

High

frequency

Carbon nanotube-epoxy

4

w0=

Na2O.3SiO2

Nylon 11

2

0

12 mol% yttria zirconia

-2

-2

0

2

4

log f(10(0)) Hz

6

[exptl.]

8

10

DRYING

WET saturated, n=0.78

10-2

10

10

10-3

ZIRCONIA COOLING

-4

230C

-5

200C

Conductivity (Siemens/m)

Conductivity (Siemens/m)

n1

10-4

DRY, n1

gradient=0.98

10-5

10

10

10

10

10

10-6

10

-6

170C

-7

140C

-8

110C

-9

80C

50C

-10

-11

10

-1

10

0

10

1

10

2

10

3

Frequency (Hz)

10-7

102

103

104

Frequency (Hz)

105

106

10

4

10

5

10

6

ELECTRICAL NETWORKS

•ANOMALOUS POWER LAW FREQUENCY

DEPENDENCES ARE AC CHARACTERISTICS OF

RANDOM ELECTRICAL NETWORKS FORMED BY

SAMPLE MICROSTRUCTURE.

•THERE IS NO NEED TO INTRODUCE ANY “NEW

PHYSICS” TO EXPLAIN THE ANOMALOUS POWER

LAW FREQUENCY DEPENDENCES.

APPLICATIONS: DESIGN OF COMPOSITES

WITH SPECIFIC DIELECTRIC/CONDUCTION

PROPERTIES.

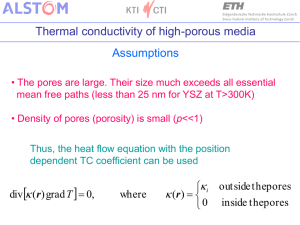

Thermal conductivity equivalent

10

0.1

-1

AC Conductance (ohm )

Network thermal conductivity

1

0.01

-1

R

1E-3

k2 (constant)

1E-4

1E-5

wC

1E-6

k1 (variable, low to high)

1E-7

1E-8

1E-9

1

10

100

1000

10000

100000 1000000

Frequency (Hz)

log(k1/k2)

1E7

1E8

1E9

-1

Conductivity Sm

0.1

PZT +water conductivity

(a)

0.01

10000

slope -0.22

1000

2

10

3

10

4

10

Keff (W/ m K)

Frequency (Hz)

5

10

6

10

Rel. Permittivity

PZT + water

rel. permittivity

(b)

50% k1, 50% k2

mixture

T= 0ºC

Measure steady

state DT to

calculate

effective

conductivity

Base constrained to

same temperature

Apply constant heat flux

3

equivalent

conductivity, K

conductivity

effective

loglog

Slope = 1 line

for reference

2

1

Slope = 0.5 line

for reference

0

-1

-2

k2 = 1

50% k1 , 50% k2

12 randomised cases

30 x 30 array

Slope = 1 line

for reference

-3

-4

-5

-4

-3

-2

-1

0

1

2

log component conductivity, k1

K(k1,k2) = k10.5. k20.5

3

4

5

k2 (blue) constant

k1 (purple variable)

3

Slope = 1 line

for reference

log equivalent conductivity, K

2

1

0

Slope = 0.5 line

for reference

-1

-2

-3

k2 = 1

50% k1 , 50% k2

12 randomised cases

30 x 30 array

Slope = 1 line

for reference

-4

-5

-4

-3

-2

-1

0

1

2

log component conductivity, k1

3

4

5

4

log equivalent conductivity, K

3

2

1

0

Slope = 0.7 line

for reference

-1

-2

k2 = 1

70% k1 , 30% k2

12 randomised cases

30 x 30 array

-3

-4

-5

-5

-4

-3

-2

-1

0

1

2

log component conductivity, k 1

K(k1,k2) = k10.7. k20.3

3

4

5

log equivalent conductivity, K

0.5

0

Slope = 0.3 line

for reference

-0.5

k2 = 1

30% k1 , 70% k2

12 randomised cases

30 x 30 array

-1

-5

-4

-3

-2

-1

0

1

2

log component conductivity, k 1

K(k1,k2) = k10.3. k20.7

3

4

5

Mechanical Network

A truss made from

random mix of

springs k1 and k2

with volume

fractions 1 and 2

Rapid protoype:

Polyamide

Infiltrate: Epoxy

50vol.% Polyamide

50vol.% Epoxy

• dynamic modulus (E1)

• loss modulus (E2)

• tan delta (E2/E1)

from -70 to 70°C

E1,composite = (E1amide)n (E1epoxy)1-n

E

*

composite

E1

amide

iE

E

amide n

2

epoxy

1

iE

epoxy 1 n

2

*

Ecomposite

[ E amide e i ( amide ) ]n [ E epoxyei ( epoxy) ]1 n

E1,composite ( E amide ) n ( E epoxy )1 n cos{n amide amide (1 n)}

E2,composite ( E amide ) n ( E epoxy )1 n sin{n amide amide (1 n)}

1.E+10

1.E+11

1.E+10

E2 (GPa)

1.E+09

polyamide

epoxy

1.E+08

composite

1.E+08

polyamide

model

epoxy

composite

model

1.E+07

-100

-50

0

50

1.E+07

-100

100

-50

Tem perature(°C)

0

Temperature (°C)

1.4

1.2

polyamide

1

tan delta

E1 (GPa)

1.E+09

epoxy

composite

0.8

model

0.6

0.4

0.2

0

-100

-50

0

Temperature (°C)

50

100

50

100

E1,composite (E amide )n (Eepoxy )1n cos{namide amide (1 n)}

Gradient of log(Ecomposite/Eepoxy) vs. log(Eamide/Eepoxy) = n

1

0.6

0.4

0.2

0

-0.2

log(Ecomposite/Eepoxy)

0.8

y = 0.4862x - 0.0082

-0.4

-1

-0.5

0

0.5

1

log(Epolyamide /Eepoxy)

1.5

2

Conclusions

(w ) Re (iwC ) (1/ R )

K (k , k ) k k

1

2

1

1

2

S (s , s ) s s

1

*

composite

E

2

E1

amide

1

1

2

iE

1

E

amide n

2

epoxy

1

iE

epoxy 1 n

2