Talk-LB-19.1.6

advertisement

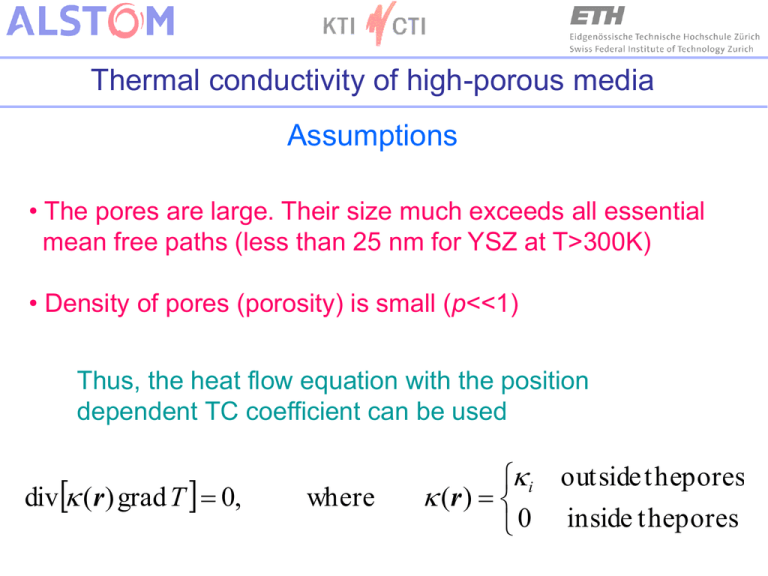

Thermal conductivity of high-porous media

Assumptions

• The pores are large. Their size much exceeds all essential

mean free paths (less than 25 nm for YSZ at T>300K)

• Density of pores (porosity) is small (p<<1)

Thus, the heat flow equation with the position

dependent TC coefficient can be used

div (r ) grad T 0,

where

i

(r )

0

outside thepores

inside thepores

heat flux

Thermal conductivity of high-porous media

z

T2

T1

TC of a homogeneous media:

QL

S(T2 T1 )

Q - heat flux, S - cross-section

heat flux

L

z

T1

T2

L

Average TC of a non-homogeneous

media:

L

(r)grad T dS

S(T2 T1 ) zconst

Thermal conductivity of high-porous media

Approach

TC is considered as a sum of its average and fluctuating components:

(r ) i (1 p) (r )

(r ) is a random value. The results are evaluated via the average

(r )(r' ) , which depends only on the distance between the points r and r’

For spherical pores, it is possible to assume:

(r ) (r ' ) e

( x x ') 2 ( y y ') 2 ( z z ') 2 / R

For non-spherical pores or cracks, it is possible to assume:

(r)(r ') e

( x x ')2 ( y y ')2 2 (z z ')2 / R

parameter 0 determines ratio of the crack dimensions

Thus, ≈ 1 for the pore, <<1 and >> 1 for the cracks of

different orientations

Thermal conductivity of high-porous media

Results

i [1 p(1 J )]

J

1

4

W ( r )

z

z

d 3r ,

3

r

W (r )

where

(0) ( r )

(0)2

Spherical pores

W ( r ) W ( r ),

J

1

3

Anisotropic pores (microcracks etc.)

W ( r ) W ( x 2 y 2 2 z 2 ),

1

sin

1 ,

1

3

/

2

(1 ) (1 )

J J ( )

ln 1 , 1

3/ 2

(1 ) ( 1)

Thermal conductivity of high-porous media

i {1 p[1 J( )]}

(1)

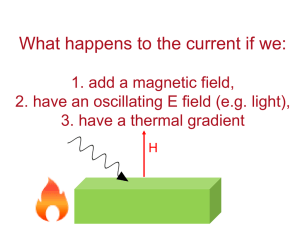

heat flux

(= 1 - pore, vary or small - crack)

heat flux

Results

1

1

Equation (1) with J = 0.3 and p as a total porosity can be used to

consider TC for all types of porosity

Thermal conductivity of high-porous media

Comments

1. TC was found to be depended on the porosity, but

independent of the pores size. This is the consequence of the

model, which has not been assumed initially. This fact is

confirmed experimentally [1].

2. The value of the factor J=1/3 for the spherical pores has been

obtained also in Ref. 2 and confirmed experimentally [1]. The

close value J=1/2 has been tested in [1,3].

3. The effect of anisotropy of TC along and across the plasma

sprayed PSZ coating was found to be small in two different

models of simulations [4] in agreement with Eq. (1).

References

1. K. Schlichting, N. Padture, P. Klemens. J. Materials Sci. 36, 3003 (2001)

2. K. Schlichting, N. Padture, P. Klemens, in “Thermal Conductivity 25” ed. By C.

Uher and D. Morelli (Technomic, Lancaster, PA, USA, 2000) p.162

3. S. Raghavan et al.,Scripta Materiala 39, 1119 (1998)

4. Z. Wang et al., Acta Materialia 51, 5319 (2003)

Thermal conductivity of high-porous media

Unclear questions and Next steps

- Is it possible to consider porosity p = 0.3 as small?

Yes, because it results in correction ~p/3<<1

No, the porosity p=0.7 means total destruction of the coating

- What value should be used as i ?

As the first approximation the intrinsic (defect-free) TC can be

used; nevertheless, the effect of the grain boundaries should be

testified.

1. Possible breaking bounds of the p<<1 approximation should be

investigated

2. The radiative component of TC should be considered

3. Experimental data of TC measurements for the specimens of

different porosity are necessary to check Eq. (1)