LACT Units - Angus Measurement

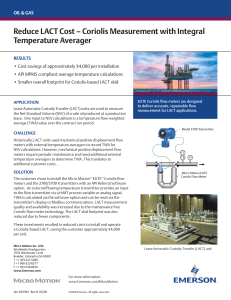

advertisement

Lease Automatic Custody Transfer LACT Units LACT Units Requirements of a LACT unit – Control operation of the system – Accurately measure the quantity transferred – Monitor the crude oil quality and prevent transfer of non-merchantable oil – Obtain a representative sample – Provide facilities for periodic proving LACT Units Control Functions of a LACT unit – Detects level in the lease tank and starts and stops the pump which forces oil through the LACT unit – Shuts down flow if rate is out of the desired range for accurate meter operation – Shuts down flow once the maximum allowable oil has been transferred – Operates the solenoid which extracts a sample proportional to flow – Diverts flow back to the tank when S&W content is too high – Actuate alarms as required LACT Units Components of a LACT unit – – – – – – – – – – Charge/Transfer Pump S&W Monitor Diverter Valve Strainer/Air Eliminator Sample System Flow Meter Meter Prover Loop Back Pressure Valve Check Valve Control Panel LACT Units Typical LACT configuration LACT Units Why Coriolis Meters? – Multi-variable Measurement • Mass, Volume, Density, Temperature Reduces cost of ownership – Non-intrusive measurement Displaces mechanical meters • No moving parts • Measures slurries nor damaged by slugs of air • No straight pipe runs required – Maintenance • No mechanical parts to wear • Reduced calibration – Accuracy • High turndown ratio • Better than 0.15% accuracy on volume flow LACT Units Charge/Transfer Pump – The pump should produce a non-pulsating flow for the LACT unit at a pressure compatible with the pipeline carrier – Centrifugal pumps are typically used for LACT units requiring medium to high volumes at low pressure. • If high discharge pressure is required, a positive displacement pump can act as a booster pump. – Flow rate, pressure required and fluid properties determine the size of the pump. LACT Units S&W Probe – S & W probes determine free water and sediment content in crude oil by typically measuring the dielectric constant which is the ability of the fluid to act as an insulator. – The dielectric constant of oil is higher than that of water. LACT Units S&W Monitor – Solid state circuitry detects changes in the dielectric constant with sensitivity that can detect 0.1% of 1%S&W content. – An adjustable time delay and fail-safe relays operate the divert valve over a selectable setting of 0-3% S&W. – The monitor diverts flow back to a retreating facility and returns the LACT to normal operation as determined by the allowable S&W setting. LACT Units Divert Valve – Divert valves have the primary function to fail closed when any of the following occurs: • Excess S&W • • • • Loss of power Loss of supply pressure Low level in the lease tank Meter failure condition LACT Units Strainer – Strainers are installed upstream of the flowmeter to protect the meter and the other elements of the4 system from being damaged by foreign materials such as pipe scale, pebbles, and large debris that may be entrained. LACT Units Air Eliminator – Why use an air eliminator? • Large amounts of free air compromises meter accuracy and can lead to overspeeding of mechanical type meters. • To insure accurate liquid measurement, it is necessary to remove all vapor and free all entrained air from the system. LACT Units Deaerator – Float operated valve principle – High capacity air elimination – Vertical tank facilitates installation – Wide variety of materials and pressure ratings – Various venting and connection applications – Low maintenance LACT Units Sample System – The components which make up a typical system include • • • • Static mixer Sample probe Extraction device Sample Receiver/Mixer LACT Units Static Mixer The optional static mixer is installed upstream of the sample probe. Rigid elements split, rearrange, and recombine component streams into smaller and smaller layers until one homogeneous stream exits. LACT Units Sample Probe – The sample probe extends into the center third of the pipe facing the flow. – The sample probe is installed in a horizontal position in a vertical run of pipe. – The extraction device is pulsed by the meter to extract a fixed quantity of sample during normal operation of the LACT unit. LACT Units Sample Receiver – The sample container is sized to allow adequate storage during the total transfer period. – The fluid is stored under pressure and the container is vapor tight to prevent evaporation. – The fluid is tested at the end of the period to determine the quality for custody transfer/net volume calculations. LACT Units Centrifuge Tube – Centrifuge tubes hold the sample and the appropriate solvent or demulsifier if necessary. – The tube is heated to a specified temperature and rotated in a centrifuge for a specific amount of time at a specific speed. The S&W is forced to the bottom of the tube where the amount is read on the scale. LACT Units Hydrometer – Hydrometers are utilized to prove the output of a densitometer or to obtain the gravity of a sample. Accurate temperature measurement is important. If light ends escape from your sample, your hydrometer reading will not match your densitometer reading. LACT Units Temperature Averager – Temperature averagers provide a true average of the process temperature based on volume or time. – Average temperature is utilized for calculation of net volume during a batch cycle, such as the end of the month. LACT Units The LACT Controller provides: – Local totalization – High speed pulse output for proving – Two scaled pulse outputs for remote monitoring and pacing of the sample system – Three analog outputs for flow rate, temperature and density LACT Units Meter Proving Loop LACT Units Back Pressure Valve The purpose of the back pressure valve is to maintain a constant pressure on the flowmeter to prevent cavitation and to control flow rate if a centrifugal pump is used. The back pressure setting should always be above the vapor pressure of the fluid. LACT Units