Ductility - Fedestructuras

advertisement

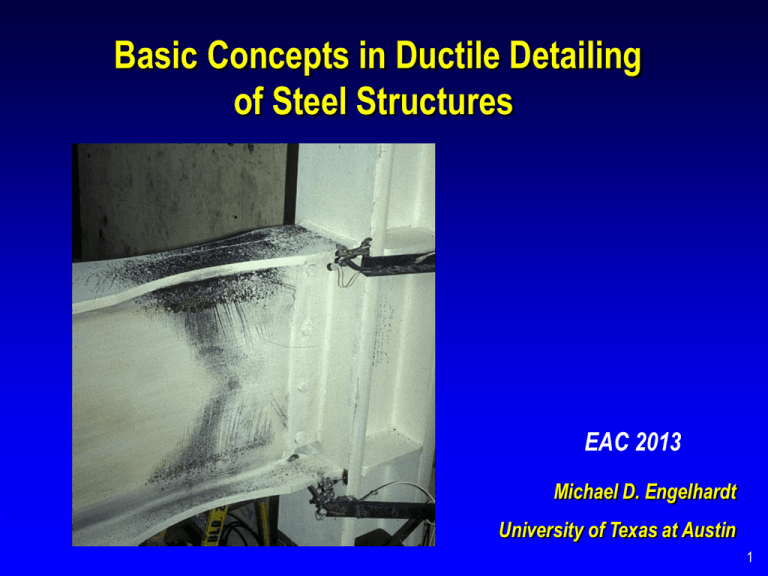

Basic Concepts in Ductile Detailing of Steel Structures EAC 2013 Michael D. Engelhardt University of Texas at Austin 1 Overview of Presentation • • • What is Ductility ? Why is Ductility Important ? How Do We Achieve Ductility in Steel Structures ? • Ductility in Seismic-Resistant Design 2 What is Ductility ? Ductility: The ability to sustain large inelastic deformations without significant loss in strength. Ductility = inelastic deformation capacity Ductility: - material response - structural component response (members and connections) - global frame response 3 Δ F F Ductility Fyield Δ 4 How is ductility developed in steel structures ? Δ F F Ductility = Yielding Loss of load carrying capability: Instability Fracture Δ 5 Why is Ductility Important? Permits redistribution of internal stresses and forces Increases strength of members, connections and structures Permits design based on simple equilibrium models Results in more robust structures Provides warning of failure Permits structure to survive severe earthquake loading 6 Why Ductility ? Permits redistribution of internal stresses and forces Increases strength of members, connections and structures Permits design based on simple equilibrium models Results in more robust structures Provides warning of failure Permits structure to survive severe earthquake loading 7 General Philosophy for Earthquake-Resistant Design Objective: Prevent loss of life by preventing collapse in the extreme earthquake likely to occur at a building site. Objectives are not to: - limit damage - maintain function - provide for easy repair Design Approach: Survive earthquake by providing large ductility rather than large strength 8 Δ H H Helastic 3/4 *Helastic 1/2 *Helastic Available Ductility Required Strength 1/4 *Helastic MAX 9 Δ H H Helastic 3/4 *Helastic Observations: We can trade strength for ductility 1/2 *Helastic 1/4 *Helastic MAX 10 Δ H H Helastic 3/4 *Helastic Observations: Ductility = Damage 1/2 *Helastic 1/4 *Helastic MAX 11 Δ H H Helastic 3/4 *Helastic Observations: The maximum lateral load a structure will see in an earthquake is equal to the lateral strength of the structure 1/2 *Helastic 1/4 *Helastic MAX 12 How Do We Achieve Ductility in Steel Structures ? 13 Achieving Ductile Response.... Ductile Limit States Must Precede Brittle Limit States 14 Example gusset plate double angle tension member P P Ductile Limit State: Gross-section yielding of tension member Brittle Limit States: Net-section fracture of tension member Block-shear fracture of tension member Net-section fracture of gusset plate Block-shear fracture of gusset plate Bolt shear fracture Plate bearing failure in double angles or gusset 15 double angle tension member P P Example: Gross-section yielding of tension member must precede net section fracture of tension member Gross-section yield: Pyield = Ag Fy Net-section fracture: Pfracture = Ae Fu 16 double angle tension member P P Pyield Pfracture The required strength for brittle limit states is defined by the capacity of the ductile element Ag F y Ae F u Ae Fy Ag Fu Fy Fu = yield ratio Steels with a low yield ratio are preferable for ductile behavior 17 double angle tension member P P Example: Gross-section yielding of tension member must precede bolt shear fracture Gross-section yield: Pyield = Ag Fy Bolt shear fracture: Pbolt-fracture = nb ns Ab Fv 18 double angle tension member P P Pyield Pbolt-fracture The required strength for brittle limit states is defined by the capacity of the ductile element The ductile element must be the weakest element in the load path 19 double angle tension member P P Example: Bolts: 3 - 3/4" A325-X double shear Ab = 0.44 in2 Fv = 0.563 x 120 ksi = 68 ksi Pbolt-fracture = 3 x 0.44 in2 x 68 ksi x 2 = 180k Angles: 2L 4 x 4 x 1/4 A36 Ag = 3.87 in2 Pyield = 3.87 in2 x 36 ksi = 139k 20 double angle tension member P P Pyield Pbolt-fracture Pyield = 139k Pbolt-fracture = 180k OK What if the actual yield stress for the A36 angles is greater than 36 ksi? Say, for example, the actual yield stress for the A36 angle is 54 ksi. 21 double angle tension member P P Pyield Pbolt-fracture Pyield = 3.87 in2 x 54 ksi = 209k Pbolt-fracture = 180k Pyield Pbolt-fracture Bolt fracture will occur before yield of angles non-ductile behavior 22 double angle tension member P P Pyield Pbrittle Stronger is not better in the ductile element (Ductile element must be weakest element in the load path) For ductile response: must consider material overstrength in ductile element 23 double angle tension member P P Pyield Pbrittle The required strength for brittle limit states is defined by the expected capacity of the ductile element (not minimum specified capacity) Pyield = Ag RyFy Ry Fy = expected yield stress of angles 24 Achieving Ductile Response.... Ductile Limit States Must Precede Brittle Limit States Define the required strength for brittle limit states based on the expected yield capacity of ductile element The ductile element must be the weakest in the load path Unanticipated overstrength in the ductile element can lead to non-ductile behavior. Steels with a low value of yield ratio, Fy / Fu are preferable for ductile elements 25 Achieving Ductile Response.... Connection response is generally non-ductile..... Connections should be stronger than connected members 26 27 28 29 30 31 Achieving Ductile Response.... Be cautious of high-strength steels 32 General Trends: As Fy Elongation (material ductility) Fy / Fu Ref: Salmon and Johnson - Steel Structures: Design and Behavior 33 Achieving Ductile Response.... Be cautious of high-strength steels High strength steels are generally less ductile (lower elongations) and generally have a higher yield ratio. High strength steels are generally undesirable for ductile elements 34 Achieving Ductile Response.... Use Sections with Low Width-Thickness Ratios and Adequate Lateral Bracing 35 Effect of Local Buckling on Flexural Strength and Ductility q M M Mp Increasing b / t q 36 Moment Capacity Ductility Plastic Buckling Mp Inelastic Buckling 0.7 My Elastic Buckling hd p r Width-Thickness Ratio (b/t) 37 Moment Capacity Ductility Plastic Buckling Mp Inelastic Buckling 0.7 My Elastic Buckling Slender Element Sections hd p r Width-Thickness Ratio (b/t) 38 Moment Capacity Ductility Plastic Buckling Mp Inelastic Buckling 0.7 My Elastic Buckling Noncompact Sections hd p r Width-Thickness Ratio (b/t) 39 Moment Capacity Ductility Plastic Buckling Mp Inelastic Buckling 0.7 My Elastic Buckling Compact Sections hd p r Width-Thickness Ratio (b/t) 40 Moment Capacity Ductility Plastic Buckling Mp Inelastic Buckling 0.7 My Elastic Buckling Highly Ductile Sections (for seismic design) hd p r Width-Thickness Ratio (b/t) 41 Local buckling of noncompact and slender element sections 42 Local buckling of moment frame beam with highly ductile compactness ( < hd ) ..... 43 5000 Bending Moment (kN-m) 4000 Mp 3000 2000 1000 0 -1000 -2000 -3000 Mp -4000 -5000 -0.05 RBS Connection -0.04 -0.03 -0.02 -0.01 0 0.01 0.02 0.03 0.04 0.05 Drift Angle (radian) 44 Local buckling of a shear yielding EBF link with highly ductile compactness ( < hd ) ..... 45 Link Shear Force (kips) 200 150 100 50 0 -50 -100 -150 -200 -0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08 Link Rotation, g (rad) 46 Effect of Local Buckling on Ductility For highly ductile flexural response: bf Example: W-Shape tf h tw 47 Beam Flanges Highly Ductile Compactness: bf E 0.30 2t f Fy Beam Web Highly Ductile Compactness: E h 2.45 tw Fy 48 Lateral Torsional Buckling Lateral torsional buckling controlled by: Lb ry Lb = distance between beam lateral braces ry = weak axis radius of gyration Beam lateral braces Lb Lb 49 Effect of Lateral Torsional Buckling on Flexural Strength and Ductility: q M M Mp Increasing Lb / ry q 50 51 Effect of Lateral Buckling on Ductility For highly ductile flexural response: E Lb 0.086 Fy ry For Fy = 50 ksi: E 0.086 Fy ry = 50 ry 52 Achieving Ductile Response.... Recognize that buckling of a compression member is non-ductile 53 Pcr d P Pcr d 54 Experimental Behavior of Brace Under Cyclic Axial Loading W6x20 Kl/r = 80 P d 55 How Do We Achieve Ductile Response in Steel Structures ? • Ductile limit states must precede brittle limit states Ductile elements must be the weakest in the load path Stronger is not better in ductile elements Define Required Strength for brittle limit states based on expected yield capacity of ductile element • Provide connections that are stronger than members • Avoid high strength steels in ductile elements • Use cross-sections with low b/t ratios • Provide adequate lateral bracing • Recognize that compression member buckling is non-ductile 56 How Do We Achieve Ductile Response in Steel Structures ? 57 Ductile Detailing for Seismic Resistance High Ductility Steel Systems for Lateral Resistance: • Special Moment Frames • Special Concentrically Braced Frames • Eccentrically Braced Frames • Buckling Restrained Braced Frames • Special Plate Shear Walls 58 Ductile Detailing for Seismic Resistance • • • Choose frame elements ("fuses") that will yield in an earthquake. Detail "fuses" to sustain large inelastic deformations prior to the onset of fracture or instability (i.e. , detail fuses for ductility). Design all other frame elements to be stronger than the fuses, i.e., design all other frame elements to develop the capacity of the fuses. 59 Special Moment Frame (SMF) Ductile fuse: Flexural yielding of beams 60 Inelastic Response of a Special Moment Frame Fuse: Flexural Yielding of Beams Detail beam for ductile flexural response: • no high strength steels • low b/t ratios (highly ductile ) • beam lateral bracing (per seismic req'ts) 61 Inelastic Response of a Special Moment Frame Design all other frame elements to be stronger than the beam: • Connections • Beam-to-column connections • Column splices • Column bases • Column buckling capacity • Column flexural capacity 62 63 Special Concentrically Braced Frame Ductile fuse: tension yielding of braces. 64 Inelastic Response of an SCBF Tension Brace: Yields (ductile) Compression Brace: Buckles (nonductile) 65 Inelastic Response of CBFs under Earthquake Loading Compression Brace (previously in tension): Buckles (nonductile) Connections, columns and beams: designed to be stronger than braces Tension Brace (previously buckled in compression): Yields (ductile) 66 67 68 69 Eccentrically Braced Frames (EBFs) Ductile fuse: Shear yielding of links 70 Link Link 71 Inelastic Response of an EBF 72 73 Braces, beam segments outside of link, columns, connections: designed to be stronger than link 74 Buckling-Restrained Braced Frames (BRBFs) Ductile fuse: Tension yielding and compression yielding of Buckling Restrained Braces 75 Buckling-Restrained Brace BucklingRestrained Brace: Steel Core + Casing Casing Steel Core 76 A A Buckling-Restrained Brace Casing BucklingRestrained Brace: Steel Core + Casing Steel Core Steel jacket Mortar Debonding material Section A-A 77 Inelastic Response of BRBFs 78 Tension Brace: Yields Compression Brace: Yields 79 Compression Brace: Yields Tension Brace: Yields Connections, columns and beams: designed to be stronger than braces 80 Special Plate Shear Walls (SPSW) Ductile fuse: Tension field yielding of web panels 81 Inelastic Response of a SPSW Development yielding along tension diagonals Shear buckling Columns, beams and connections: designed to be stronger than web panel 82 Ductile Fuses: Special Moment Frames: Beams: Flexural Yielding Special Concentrically Braced Frames: Braces: Tension Yielding Eccentrically Braced Frames: Links: Shear Yielding Buckling Restrained Braced Frames: Braces: Tension and Compression Yielding Special Plate Shear Walls: Web Panels: Tension Field Yielding 83 Summary • Ductility = Inelastic Deformation Capacity • Ductility Important in all Structures • Ductility Key Element of Seismic Resistance 84 Summary • Achieving Ductility - Simple Rules......... avoid high strength steels use sections with low b/t's and adequate lateral bracing design connections and other brittle elements to be stronger than ductile members For seismic-resistant structures: Follow AISC Seismic Provisions 85