ENMA 6010:

Data Flow Diagrams

Modeling System Functions

Primary Reference: Wikipedia – Data Flow Diagrams

©2010 – Mark Polczynski

All rights reserved

ENMA 6010: Data Flow Diagrams

1

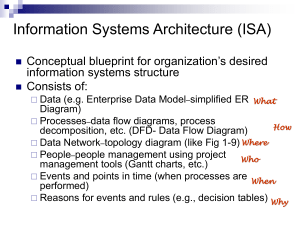

We will be studying four modeling approaches:

Detail

• Data flow diagram – system function

• State transition diagrams – time dependent behavior

• Entity relationship diagram – stored data/material

• Process flow diagrams – actions and decisions

To understand the rationale behind this modeling tool,

We need to review the reasons for modeling,

And the characteristics of good model.

ENMA 6010: Data Flow Diagrams

2

Goals of System Modeling:

1.

To focus on important system features while downplaying less important

features,

2.

To discuss changes and corrections to the user’s requirements at low cost

and with minimal risk,

3.

To verify that we understand the user’s environment,

4.

To verify that we have documented our understanding in a way that

would allow others to construct/maintain the system.

Data flow diagrams are a good tool for modeling system functions.

Additional tools are typically required to meet this complete set of goals.

ENMA 6010: Data Flow Diagrams

3

Characteristics of Good Models

1.

Graphical, with support for detailed text descriptions: Picture is worth a

thousand words picture links to a thousand words.

2.

Top-down partitionable: Globe Continents Countries

3.

Minimally redundant: Make changes in just one place in the model.

4.

Transparent: Requires no expertise in

model building to understand the model.

ENMA 6010: Data Flow Diagrams

4

Data Flow Diagrams

Low-hanging

apple

Data flow diagrams focus on:

Pick apple

1.

Processes within a system that

a) Transform data/material

inputs to outputs

Picked apple

Picked apples

b) Store data/materials

2.

Flows

a) Within the system between the processes and stores,

b) To/from entities outside of the system.

ENMA 6010: Data Flow Diagrams

5

Origins and Uses

• Data flow diagrams began to be widely used in the 1970’s.

• They are a key tool in software engineering.

• They are associated with the general field of structured analysis.

• So, they are good for modeling business systems.

• They focus on data (information), but in a general sense, they can

represent any type of flow, e.g., money flow, material flow.

• Thus, they are a good tool for modeling inventory flow and storage in a

manufacturing system.

• But in their basic form they are primarily qualitative vs. quantitative.

• That being said, they can be an excellent high-level representation for

streamlining systems and reducing inventory.

ENMA 6010: Data Flow Diagrams

6

Data, Materials, and Objects

•

Because DFDs came out of software engineering, the focus was on data.

•

But as we see, the modeling approach accommodates any kind of flow,

including data, materials, money (which is now data, not materials like

silver and gold), etc.

•

So here, we will just use the generic term “object” for whatever is flowing.

•

As it turns out, this term will show up in other modeling tools.

ENMA 6010: Data Flow Diagrams

7

Data Flow Diagram Symbols

Process

Process (or function) which transforms data or material

(objects) inputs to outputs. Black box - does not indicate

how or when the transform is done. Shorthand = “bubble”.

Store

Place where objects come to rest. You only store object

that the system needs to “memorize”.

Flow

Directed pathways between processes, stores, and

terminators. Use a different flow for each type of object.

External

Terminator

Entities outside the system. Where flows start and end.

Outside the scope of the model.

ENMA 6010: Data Flow Diagrams

8

Example Data Flow Diagram: Book Shipping and Receiving System

Alternate

shape

From Yourdon –

Some inconsistencies!

ENMA 6010: Data Flow Diagrams

9

Naming Data Flow Diagram Elements

Constructing and understanding data flow diagrams can be enhanced by

sticking to some simple naming conventions:

Process

Verb-object phrase: “Calculate sales tax”. Don’t use the name

of the person/computer/etc. Rather, describe the function

(keep it general).

Flow

Noun: Name of the object flowing, e.g. “Apple”. If it is

“Apple, Pear, Banana”, and you process them all the same

way call it “Fruit”.

Store

Typically, plural of the object being stored: “Apples”

External

Terminator

This is typically some physically distinct entity – person,

computer, company, agency, another system.

ENMA 6010: Data Flow Diagrams

10

Some Implementation Notes:

• If you are struggling with defining meaningful names for diagram elements

(e.g. “valid tax return” vs. “input”), then you probably don’t understand the

system.

• To increase clarity, you can show terminators and stores more than one

time in a diagram (see BODS example), but each process bubble can

appear only once.

• Terminators are outside the system being modeled. If you start drawing

flows between terminators, then you are, in essence, expanding the

boundaries of the system you are modeling.

• You can’t have processes or stores with inputs but no outputs (sinks), or

outputs but no inputs (sources).

• Only terminators can be sources or sinks of objects.

ENMA 6010: Data Flow Diagrams

11

Implementation Note on Terminators:

• Usually, your customer defines the scope of the system that you will be

modeling.

• This defines the terminators for the DFD.

• Terminators are outside of the system, and, by definition, the modeler

cannot change the contents, organization, or internal procedures of

terminators.

• Therefore, the DFD is an essential document for customer interaction and

model scope definition.

• It is essential to controlling customer expectations.

ENMA 6010: Data Flow Diagrams

12

Further Information on Implementation

The Yourdon text has detailed guidelines on do’s and dont’s of drawing DFDs.

We will not cover this detail here, but it is highly recommended that someone

on your team reads through this and does a thorough check of your project

DFD.

That being said, there are some key issues we still need to touch on:

•

Logical model vs. physical model,

•

Top-down modeling,

•

Bottom-up modeling,

•

Data dictionary

•

Extensions for real-time control.

ENMA 6010: Data Flow Diagrams

13

DFD Logical Model vs. Physical Model

• The logical model contains only the diagram elements absolutely needed

to make a system meet the customer requirements.

• This is sometimes termed the essential model.

• The physical model contains process, store, and flow elements that are

added by the designer to make implementation easier.

• This may be called the environmental model.

• The logical model is implementation independent…

…The physical model is implementation dependent.

ENMA 6010: Data Flow Diagrams

14

Great! What Does That Mean?!

This is a very critical distinction…

and an essential part of building good models.

Let’s start with a simple example: Making a PBJ sandwich…

ENMA 6010: Data Flow Diagrams

15

Processes and Flow

Here is the logical model for preparing your sandwich.

The model contains all the essential processes and flows.

But what if you were preparing the sandwich in the morning,

and it is supposed to be your lunch?

ENMA 6010: Data Flow Diagrams

16

Process, Flow, and Storage

Here, the sandwich is constructed and stored

for later consumption.

Thus, the storage element is required to

implement this system,

But it is not required to make a PBJ sandwich.

ENMA 6010: Data Flow Diagrams

17

Logical Model:

Ideally, orders are

processed

immediately.

Physical Model:

In this implementation

of the ideal system,

orders are processed in

batches, so they need

to be stored before

processing.

Un-Lean

This is an example of a physical model containing

an implementation-dependent data store.

ENMA 6010: Data Flow Diagrams

18

Here is an example of a necessary data store in an order entry system…

Here, it is absolutely necessary to keep a long-term record of Orders

for government accounting regulations, warrantee coverage, etc…

So this should be included in the logical model.

ENMA 6010: Data Flow Diagrams

19

Using Logical and Physical Models

Typically, you develop the logical model first to understand the system,

Then build the physical model to use as a design spec showing actual

implementation.

The physical model represents compromises that add cost to the system.

In the physical model, the diagram elements turn into the names of:

• People,

• Physical pieces of hardware,

• Software packages,

• File or databases,

• Inventory locations,

• Etc…

ENMA 6010: Data Flow Diagrams

20

Buffers and Work-In-Process

• In practice, a primary difference between logical and physical models lies in

the stores.

• In logical models, only the objects that needs to be stored for future use

(“memorized” for data) appear in the model.

• The added data stores in physical models represent buffers needed for realworld systems to level out flow between processes.

• Since data flow and data store can also represent material flow and material

store, data stores represent inventory or work-in-process.

• Comparison of logical and physical models is an excellent way of

identifying and reducing work-in-process.

Goal is to make physical model look like logical model.

ENMA 6010: Data Flow Diagrams

21

Logical vs. Physical Model

In a sense, the logical model represents an ideal future state of a system.

Thus, the logical represents a “to-be” model that our kaizen efforts should be

directed toward.

It is important to build the logical model first, since we really need a description

of the to-be state.

Now, whether you are designing a new system or analyzing an old system, you

must always ask:

•

Why do I need this storage element in the physical model?

•

How could I eliminate the need for this physical element?

ENMA 6010: Data Flow Diagrams

22

Top-Down Modeling

• Obviously, a system with many processes, flows, and stores can result

in a data flow diagram that is impossible to understand, maintain, and

improve.

• The field of structured analysis allows top-down design, modeling, and

documentation, where processes are decomposed into multiple sublevels.

• Data flow diagrams support this approach.

Let’s see how this works…

ENMA 6010: Data Flow Diagrams

23

Returning to the Book Order and Delivery System, we see a bunch of

process blocks, storage blocks, terminator blocks, and flows.

So we can easily find the system boundaries right away…

Process

Store

Flow

External

Terminator

ENMA 6010: Data Flow Diagrams

24

Context Diagram

By observing system boundaries, we can draw a Context Diagram which shows

the system we are analyzing (target system), and the systems that our system

interacts with.

Target system

for analysis

Note: Drawing the Context

Diagram resolved some

inconsistencies in Yourdon’s

original example!

ENMA 6010: Data Flow Diagrams

25

Context Diagram

The Context Diagram is the top level in our top-down model.

Target system

for modeling

Once we settle on what is inside and outside the system we will model,

And how our system interacts with the outside world,

We can focus our attention on modeling the target system.

ENMA 6010: Data Flow Diagrams

26

Level 0

Returning to Yourdon’s example, Level 0 shows the major functions and

stores inside the Context Diagram target system.

Note the

numbering on

the functions

ENMA 6010: Data Flow Diagrams

27

Top-Down Modeling – Process Decomposition

Next, you draw data flow diagrams for what is happening inside each Level 0

function, etc….

Note the numbering convention

on the processes.

System

Context Diagram

2

3

3.1

3.3

1

Level 0

3.2

Level 1

Level 2

ENMA 6010: Data Flow Diagrams

28

Top-Down Decomposition Implementation Notes:

•

Try to limit each DFD level to about 6 processes and stores (1 .ppt slide).

•

If you have more than 6 processes, try to group them, and then create

sub-level showing detail.

•

You will rarely go beyond Level 2.

Remember!

DFD just shows:

•

WHAT processes (transforms, functions) are performed on data/materials.

•

Not HOW the processes are performed.

•

We’ll use other tools to show the HOWs.

ENMA 6010: Data Flow Diagrams

29

Top-Down Modeling for System Design

The top-down approach works well when designing a new system.

Since you don’t know details, you can start by identifying the main object

transformations.

Then figure out later (or delegate) how each major transformation will be done.

This generates the lower levels of the diagram.

Note: As you do this, you may choose to change the boundaries of upper layers,

e.g., move Process 3.3 inside of Process 2.

3

3.1

3.3

2

3.2

1

Level 0

Level 1

ENMA 6010: Data Flow Diagrams

30

DFD Modeling Process: Bottom-Up Modeling

We saw how to build a top-down for a new process, but it is also possible to draw

DFDs using a bottom-up approach.

Bottom-up works OK for existing systems, but kind of difficult for systems that

don’t exist yet. Here’s how you do it:

1. Start by just writing down “events” (things that happen in your system) on

post-it notes. These events represent the process elements (bubbles).

2. For each process, identify what data or material is needed for the process

function.

3. Find the process that provides the needed object and draw a flow line.

4. Create new processes where there is no source of the required object.

5. Add stores where they are absolutely required.

6. Processes which are read-only or write-only are terminators, or you haven’t

analyzed the system correctly.

ENMA 6010: Data Flow Diagrams

31

Enter

Process

Walkthrough

Group and

Organize

Test

Model

List all events

that occur in the system

Attach flows in and out

to events (processes)

Walk through system

operation using the

model

For each event, identify

the data/material in

Attach data/material

stores to flow

in and out

For each event, identify

data/material out

Create diagram from

flow/process/store sets

sets

For each data/material,

identify stores as

needed

Eliminate duplicate

flow/process/store

elements

Identify missing

processes, flows, and

stores

Exit

Process Flow Diagram for

Bottom-Up Data Flow

Diagramming

No

Put events,

data/materials, stores

on self-stick notes

Review

and Revise

Model

accurate?

Yes

Use the

model

ENMA 6010: Data Flow Diagrams

32

Data Dictionary

You can collect the names of all

of the stored objects into a text

document.

Then, you can describe the

characteristics of that object.

This is the data dictionary…

It consists of what it is that we

need to “remember” about each

object.

Of course, you can treat

materials just like data, which

results in an inventory list vs. a

data dictionary

ENMA 6010: Data Flow Diagrams

33

Extensions for Real-Time Control

Consider our PBJ System.

Assumedly, we just don’t keep making and storing sandwiches,

Or just keep eating sandwiches all day long…

So, what turns the bubbles

on and off?

ENMA 6010: Data Flow Diagrams

34

Control

flow

Control

function

ENMA 6010: Data Flow Diagrams

35

Control Function

•

The control function coordinates the activities of the other DFD functions.

•

Control function inputs and outputs are 1-bit on/off yes/no signals.

•

No data/materials flowing on control lines!

•

These signals “wake up” other functions when the function needs to

transform inputs to outputs.

•

These could be expected or unexpected conditions.

•

Typically there is no more than one control function for a particular data

flow diagram.

ENMA 6010: Data Flow Diagrams

36

What A Mess!!

Yes, these models can get pretty complicated and messy,

But whose fault is that?!

One way to help keep things under control is to put your DFDs in matrix format:

To

Function 1

Function 2

…

Terminator 1

…

…

Terminator 1

…

Function 2

Function 1

From

Flow A

Store X

Flow B

ENMA 6010: Data Flow Diagrams

37

OK, let’s convert Yourdon’s example to matrix form…

Start with functions:

1. Receive order

2. Ship books

3. Collect payments

Then terminators:

• Customers

• Warehouse

Now build the matrix…

ENMA 6010: Data Flow Diagrams

38

DFD Matrix – Step 1

To

Warehouse

Customers

3. Collect

payments

2. Ship

books

1. Receive

order

From

1. Receive order

2. Ship books

3. Collect payments

Customers

Warehouse

Now let’s fill in the cells…

ENMA 6010: Data Flow Diagrams

39

DFD Matrix – Step 2

To

1. Receive order

2. Ship books

Warehouse

S: Customers F: Orders

S: Orders

F: Books

F: Payments,

inqiries

3. Collect payments S: Invoices

Customers

Customers

3. Collect

payments

2. Ship

books

1. Receive

order

F = Flow

S = Store

From

F: Invalid

orders

F: Ship books F: Invoices

Warehouse

ENMA 6010: Data Flow Diagrams

40

Why would you do this?

To

1. Receive order

Warehouse

Customers

3. Collect

payments

2. Ship

books

1. Receive

order

From

S: Customers F: Orders

2. Ship books

S: Orders

3. Collect payments

S: Invoices

Customers

F: Invalid

orders

F: Books

F: Payments,

inqiries

F: Ship books F: Invoices

Warehouse

Does Ship books send

anything to warehouse?

Well, for example, now it’s pretty easy to go to each empty cell and ask

if there actually should be a data flow that we missed in our analysis.

ENMA 6010: Data Flow Diagrams

41

Characteristics of Good Models

1.

Graphical, with support for detailed text descriptions: Picture is worth

a thousand words picture links to a thousand words.

2.

Top-down partitionable: Globe Continents Countries

3.

Minimally redundant: Make changes in just one place in the model.

4.

Transparent: Requires no expertise in model building to understand the

model.

Data flow diagrams have these characteristics.

ENMA 6010: Data Flow Diagrams

42

Goals of System Modeling:

1.

To focus on important system features while downplaying less important

features,

2.

To discuss changes and corrections to the user’s requirements at low cost

and with minimal risk,

3.

To verify that we understand the user’s environment,

4.

To verify that we have documented our understanding in a way that would

allow others to construct/maintain the system.

Data flow diagrams are a good tool for modeling system functions.

Additional tools are required to meet this complete set of goals.

ENMA 6010: Data Flow Diagrams

43

We will be studying several modeling approaches, including:

Detail

• Data flow diagram – system function

• State transition diagrams – time dependent behavior

• Entity relationship diagram – stored data/material

• Process flow diagrams – actions and decisions

Can you be more specific?

ENMA 6010: Data Flow Diagrams

44

Preview of coming lectures…

State transition

diagram

Process flow

diagram

Entity relationship

diagram

ENMA 6010: Data Flow Diagrams

45

Notes on using Visio to draw data flow diagrams…

ENMA 6010: Data Flow Diagrams

46

Forget it!

See next slide

My favorite shapes…

ENMA 6010: Data Flow Diagrams

47

Start with

“Dynamic connector”…

Then select line

and right click…

Then choose

“Curved Connector”

ENMA 6010: Data Flow Diagrams

48