physical properties of materials (chapter 3) - Ivy Tech -

advertisement

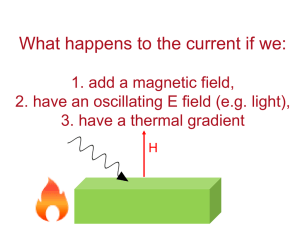

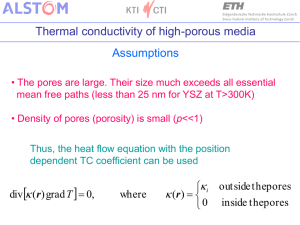

PHYSICAL PROPERTIES OF MATERIALS Chapter 3 PHYSICAL PROPERTIES • • • • • • • • • Density Melting point Specific heat Thermal conductivity Thermal expansion Electrical properties Magnetic properties Resistance to oxidation Resistance to corrosion DENSITYMASS PER UNIT VOLUME Also called specific gravity which expresses a material’s density with respect to water TABLE 3.1 PHYSICAL PROPERTIES OF SELECTED MATERIALS AT ROOM TEMPERATURE TABLE 3.2 PHYSICAL PROPERTIES OF MATERIALS, IN DESCENDING ORDER • Titanium and aluminum are among the most commonly used metal for aircraft and aerospace applications FIGURE 3.1 RATIO OF MAXIMUM YIELD STRESS TO DENSITY FOR SELECTED METALS. FIGURE 3.2 SPECIFIC STRENGTH (TENSILE STRENGTH/DENSITY) AND SPECIFIC STIFFNESS (ELASTIC MODULUS/ DENSITY) FOR VARIOUS MATERIALS AT ROOM TEMPERATURE. (SEE ALSO CHAPTER 9.) COMPOSITE MATERIALS HAVE BECOME IMPORTANT FOR THEIR HIGH SPECIFIC STRENGTH AND STIFFNESS Density • • • • • High speed equipment Textile machines Printing press Cameras High weight desirable– Counterweights – Flywheels – Ballasts – Golf clubs Elevated temperaturesspecific strength & stiffness • Turbines • Automotive • Jet engines • Gas turbines FIGURE 3.3 SPECIFIC STRENGTH (TENSILE STRENGTH/DENSITY) FOR A VARIETY OF MATERIALS AS A FUNCTION OF TEMPERATURE. NOTE THE USEFUL TEMPERATURE RANGE FOR THESE MATERIALS AND THE HIGH VALUES FOR COMPOSITE MATERIALS. MMC—METAL-MATRIX COMPOSITE; FRP—FIBERREINFORCED PLASTIC. MELTING POINTDEPENDS ON THE TEMPERATURE TO SEPARATE ITS ATOMS • Plastics have lowest useful range • Graphite and refractory metals have the highest useful range • Annealing • Heat treating • Hot-working • Alloying has a minor effect on specific heat • Temperature rise in a work piece is a function of the work done and of the specific heat of the work piece material SPECIFIC HEATTHE ENERGY TO RAISE THE TEMPERATURE OF A UNIT MASS BY 1 DEGREE THERMAL CONDUCTIVITY • The rate at which heat flows within and through a material • Metallically bonded materials (metals) generally have a higher conductivity • Ionically or covalently bonded materials (ceramics, plastics) have poor conductivity • Cooling fins • Cutting tools • Die-cast molds to conduct heat THERMAL EXPANSION • Generally, the coefficient of thermal expansion is inversely proportional to the melting point of the material • Shrink fits utilize thermal expansion and contraction-heat a part often installed on a shaft, install the part, let the part cool and contract • Thermal stress • Cracking • Warping • Loosening • Thermal fatigue results from thermal cycling • Thermal shock-cracks after just a single thermal cycle • Low expansion alloys-iron-nickel alloys with low thermal-expansion coefficients ELECTRICAL CONDUCTIVITY ELECTRICAL CONDUCTIVITY • ELECTRICAL EQUIPMENT • MACHINERY • MANFACTURING PROCESSSES • UNITS: MHO/M OR MHO/FT WHERE MHO IS THE REVERSE OF OHM, THE UNIT OF ELECTRICAL RESISTANCE • ALLOYING OF METALS RAISES THE CONDUCTIVITY CONDUCTORS: MATERIALS WITH HIGH ELECTRICAL CONDUCTIVITY • INSULATORS OR DIELECTRICS: MATERIALS WITH HIGH ELECTRICAL RESISTIVITY • ELECTRICAL RESISTIVITY IS THE INVERSE OF ELECTRICAL CONDUCTIVITY SUPERCONDUCTORS • SUPERCONDUCTIVITY IS THE PHENOMENON OF NEARZERO ELECTRICAL RESISTIVITY THAT OCCURS IN SOME MATERIALS OR ALLOYS BELOW A CRITICAL TEMPERATURE (OFTEN ABSOLUTE ZERO) • HIGH-POWER MAGNETS • MRI-MAGNETIC RESONANCE IMAGING CORROSION RESISTANCE • CORROSION REFERS TO THE DETERIORATION OF METALS AND CERAMICS • DEGRADATION REFERS TO THE DETERIORATION OF PLASTICS • FOOD • CHEMICAL • PETROLIUM INDUSTRY • MANUFACTURING OPERATIONS PITTING: LOCALIZED CORROSION OF A MATERIAL SALT…CORROSION? • CORROSION RESISTANT MATERIALS: • NONFERROUS METALS • STAINLESS STEEL • NONMETALLIC MATERIALS • STEEL & CAST IRON MUST BE PROTECTED BY COATINGS AND SURFACE TREATMENTS GALVANIC CELL • TWO ELECTRODES IN AN ELECTROLYTE IN A CORROSIVE ENVIRONMENT THAT INCLUDES MOISTURE CAUSE GALVANIC CORROSION • STRESS-CORROSION CRACKING • OXIDATION-REMOVAL OF MATERIAL BY CHEMICAL REACTION