Lecture 5

advertisement

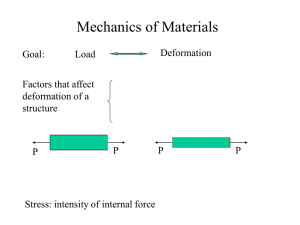

Mechanics of Materials – MAE 243 (Section 002) Spring 2008 Dr. Konstantinos A. Sierros Problem 1.4-4 A circular bar of magnesium alloy is 800 mm long. The stress-strain diagram for the material is shown in the figure. The bar is loaded in tension to an elongation of 5.6 mm, and then the load is removed. (a) What is the permanent set of the bar? (b) If the bar is reloaded, what is the proportional limit? (Hint: Use the concepts illustrated in Figs. 1-18b and 1-19.) Problem 1.5-6 A tensile test is performed on a brass specimen 10 mm in diameter using a gage length of 50 mm (see figure). When the tensile load P reaches a value of 20 kN, the distance between the gage marks has increased by 0.122 mm. (a) What is the modulus of elasticity E of the brass? (b) If the diameter decreases by 0.00830 mm, what is Poisson’s ratio? 1.6: Shear stress and strain • Shear stress acts tangential to the surface of the material and not perpendicular perpendicular tangential • Consider the bolted connection of fig. 1-24 where A is a flat bar, C a clevis and B a bolt • When load P is applied, the bar and clevis will press against the bolt and bearing stresses will be developed • The bar and clevis tend to shear the bolt Bolted connection in which the bolt is loaded in double shear FIG. 1-24 Copyright 2005 by Nelson, a division of Thomson Canada Limited This tendency is resisted by shear stresses in the bolt 1.6: Shear stress and strain • If we have a closer look from the side view (fig 1-24b) and draw a FBD (fig 124c) • Bearing stresses exerted by the clevis against the bolt appear on the left-hand side (1 and 3) • Stresses from the bar are on the righthand side (2) Bolted connection in which the bolt is loaded in double shear FIG. 1-24 • Based on the assumption of uniform stress distribution we can calculate an average bearing stress σb Copyright 2005 by Nelson, a division of Thomson Canada Limited total bearing force bearing area 1.6: Shear stress and strain • The bearing area Ab is defined as the projected area of the curved bearing surface. For example (for stresses labeled 1) the projected area on which the stresses act is a rectangle with height equal to the thickness of the clevis and width equal to the diameter of the bolt • The bearing force Fb (for stresses labeled 1) is equal to P/2 • The same area and force apply for stresses labeled 3 • For bearing stresses labeled 2 the bearing area is a rectangle with height equal to the thickness of the flat bar and width equal to the diameter of the bolt. The force is equal to P Bolted connection in which the bolt is loaded in double shear FIG. 1-24 Copyright 2005 by Nelson, a division of Thomson Canada Limited 1.6: Shear stress and strain • The FBD (c) shows that there is a tendency to shear the bolt along the cross sections mn and pq • From the FBD (d) of the portion mnqp of the bolt we see that the shear forces V act over the cut surfaces of the bolt. There are two planes of shear (plane mn and plane pq). Therefore, the bolt is in double shear • The shear stresses acting on the cross section mn are shown (e) • Shear stresses are denoted by τ 1.6: Shear stress and strain: Single shear • The axial force P in the metal bar is transmitted to the flange of the steel column through a bolt • A cross section of the column (fig 1-25b) shows more details • Fig 1-25c shows the assumed distribution of the bearing stresses acting on the bolt • Cutting through the bolt at section mn (fig 1-25d) we see the shear force V (equal to load P). V is the resultant of the shear stresses that act over the cross-sectional area of the bolt FIG. 1-25 Bolted connection in which the bolt is loaded in single shear Copyright 2005 by Nelson, a division of Thomson Canada Limited 1.6: Shear stress and strain: Single shear • Fig 1-26 shows the deformation of a bolt loaded almost to fracture in single shear FIG. 1-26 Failure of a bolt in single shear Copyright 2005 by Nelson, a division of Thomson Canada Limited 1.6: Shear stress and strain • Discussing about bolted connections we disregard friction which is produced by tightening the bolts • Average shear stress on the cross section of a bolt is obtained by dividing the total shear force V by the area A of the cross section on which it acts: • Shear stresses have the same units as normal stresses • The two previous examples (double and single shear) are examples of direct shear • Direct shear arises in the design of bolts, pins, rivets, keys, welds and glued joints 1.6: Equality of shear stresses on perpendicular planes • Consider a small rectangular parallelepiped element • Assume that a shear stress τ1 is uniformly distributed over the right-hand side area bc (τ1bc) • For equilibrium in the y direction the τ1bc must be balanced by an equal and of opposite direction shear force on the lefthand side • The forces τ1bc acting on the right-hand and left-hand side faces form a couple having a moment about z-axis equal to τ1 abc (counterclockwise direction) Small element of material subjected to shear stresses FIG. 1-27 Copyright 2005 by Nelson, a division of Thomson Canada Limited 1.6: Equality of shear stresses on perpendicular planes • Similarly, in order to have equilibrium of the element, we have a shear force τ2ac and consequently a clockwise couple of moment τ2abc • It is therefore evident that for moment equilibrium we have: τ1 = τ2 Small element of material subjected to shear stresses FIG. 1-27 Copyright 2005 by Nelson, a division of Thomson Canada Limited 1. Shear stresses on opposite and parallel faces of an element are equal in magnitude and opposite in direction 2. Shear stresses on adjacent and perpendicular faces of an element are equal in magnitude and have directions such that both stresses point toward, or both point away from, the line of intersection of the faces 1.6: Shear strain • Shear stresses acting on an element of material (fig 1-28a) are accompanied by shear strains • The lengths of the sides of the element do not change but, the shear stresses produce a change in the shape of the element • Rectangular parallelepiped becomes oblique parallelepiped. Front and rear faces become rhomboids • The angle γ (fig 1-28b) is a measure of distortion of the element and is called shear strain Element of material subjected to shear stresses and strains FIG. 1-28 Copyright 2005 by Nelson, a division of Thomson Canada Limited 1.6: Sign conventions for shear stresses and strains • We refer to the faces oriented toward the positive directions of the axes as the positive faces of the element • Right-hand, top and front faces are the positive x, y and z faces and the opposite faces are the negative ones A shear stress acting on a positive face of an element is positive if it acts in the positive direction of one of the coordinate axes and negative if it acts in the negative direction of an axis. A shear stress acting on a negative face of an element is positive if it acts in the negative direction of an axis and negative if it acts in a positive direction Shear strain in an element is positive when the angle between two positive faces, or two negative, is increased 1.6: Hooke’s law in shear • We can plot shear stress-strain diagrams • Hooke’s Law in shear: shear stress shear modulus of elasticity τ = Gγ shear strain • G has the same units as E (Young’s modulus) • G and E are also related by: Poisson’s ratio G = E / (2(1+ν)) • For mild steel G = 75 GPa and for aluminum alloys G = 28 GPa • Additional values can be found in Table H-2, Appendix H Please do not forget to correct your Statics quiz and return it on Wednesday 30th of January during class