Chapter 3

advertisement

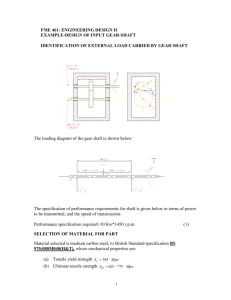

Chapter 3 – Stress and Deformation Analysis (ref MCHT 213!!) 1 Strength of Materials can really be divided into 2 categories: 1. Stress analysis: – Structure exists, material and loading known • IS IT SAFE????? 2. Design: – Determine geometry OR material based on an allowable stress (i.e. Sy/4). – Generally certain aspects are fixed. – Much more involved than analysis – why?? – Ref Chapter 1 – start with design requirements/functions/evaluation criteria,etc. Show overhead – trailer – analysis or design? how would you analyze it? 2 Possible modes of failure (mechanical)??? 1. 2. 3. 4. 5. 6. Fracture (s >> Su) Yield (s >> Sy Instability (buckling) Fatigue and wear Excessive deformation (i.e. too soft) Creep or stress relaxation (polymers) 1,2,4 – most important parameter? STRESS!!!!!! 3 Definition of Definition of Stress: •Internal Force per unit area •Intensity of internal force on a specific plane (area) passing through a point 4 Stress States: Preferred stress element for 2D stress: a) In general, can have 6 independent stresses (3 normal and 3 shear) acting at a point. b) Many practical engineering problems involve only three independent stresses – called plane stress. b) Stress state for plane stress can be summarized on a 2D element. 5 Quick Review: Basic Types of Stress (ref: MCHT213) 6 AXIAL MEMBERS: Average Normal Stress (aka Direct Normal Stress): 7 3.4 Average Normal Stress: Requirements for Average Normal Stress, s = P/A: 1. Member starts out straight and remains straight after loading 2. Homogenous, isotropic 3. Invoke St. Venant’s Principal EXAMPLES of AVERAGE NORMAL STRESS: 8 Example Normal Stress: If P = 20K lbs and A = 2 in2 s=? 9 Average Shear Stress (AKA Direct Shear Stress): t = P/As 10 Average Shear Stress: 11 Example Shear Stress: If load = 2,000 lb and bolt diameter = ½”, Find shear stress in bolt. What if double shear, what would the new shear stress be?? 12 Example: normal stress and shear stress: 13 Example 2 – direct normal and shear stress DISCUSS ONLY! 14 1.119 St. Venant’s Principle and Stress Concentration Factors, Kt: = St Venant’s: 1. Stress profile, sufficiently removed from the local effect of loads will be uniform (i.e. = P/A) 2. Stress and strain produced by statically equivalent load system will be the same. 15 St. Venant’s Principal: Note, def’m of grid uniform at middle, therefore strain and stress will be uniform. 16 Example: Look at deformation in vicinity of hole. Is it uniform??? Stress profile is not uniform. smax occurs at area of discontinuity. smax > savg 17 smax = Kt* savg smax = maximum stress savg = average stress (P/Amin) Kt = stress concentration factor 18 19 smax = Kt* savg 20 21 Find: Max Stress: 22 23 Deformation of Axial Member with Constant Load and Cross-Sectional Areas: Deformatio n PL AE Or, for multiple sections: total PL AE 24 Example: Multiple sections. Find total deformation of end A with respect to D. Area = 20 mm2. Material is steel w/ E = 200 GPa = 200 x 109 Pa: = 100 mm = 150 mm PL A/D A/D PAB L AB AE = 200 mm AE PBC L BC AE PCD L CD AE 25 First, solve for internal loads: 26 A/D A/D A/D PAB L AB PBC L BC AE AE ( 5 , 000 N )(. 1m ) AE AE ( 3 , 000 N )(. 15 m ) AE 1,350 PCD L CD ( 7 , 000 N )(. 2 m ) AE 1,350 9 AE 3 . 38 x10 4 m 0 . 338 mm (. 00002 )( 200 x10 ) How would this answer change if aluminum instead of steel???? 27 TORSION: Key points: Varies linearly with radius, . Zero at center Max at outer fiber ( = c) Constant for given . Solid vs. hollow Torsion of non-circular sections. 7. Now how to calculate torque given power and rotational speed. 1. 2. 3. 4. 5. 6. t t max c 28 The torsion formula (see derivation): Torque (N-m, Nmm or lb-in, lbft, etc) t max Tc Outer radius of shaft (m or in) J Polar moment of inertia (m4 or in4) Max shear stress in shaft (MPa, psi/ksi, etc.) or t T J 29 J = polar moment of inertia • Solid shaft: J c •Hollow shaft: 4 J 2 2 c 4 o c 4 i W For Design: T = P/n r/s N-m rpm T = 63,000 P/n lb-in hp Zp J c c 3 2 30 Stress Profiles: Shear stress profile – YOU MUST UNDERSTAND THIS!!!! Where is shear stress max? zero? How does it vary along the length and circumference? 31 32 33 34 Angle of twist - For straight sections: Torque Angle of twist (rad) Polar moment of inertia Length TL JG Modulus of Rigidity (Shear Modulus) – see back of book 35 Angle of twist for Multiple Sections: TL JG 36 If the distance between gear E and the middle gear is 12 inches, find the angle of twist between the two gears. The shaft is steel and G = 11.5 x 106 psi. 37 5.8 Stress Concentrations (last topic we’ll cover in Chapter 5) Consider the torsion member only (shaft) where do you think the stress concentrations are?? Again, stress concentrations occur where there’s an abrupt change in geometry! 38 How do we deal with stress concentrations?? t max K t nom K Tc J Based on smaller of two connected shafts 39 40 Torsion of non-circular cross-sections: t T Q TL GK Where Q and K are determined based on cross-section from F3-10 41 Also, see equations for closed thin walled tubes! See HO: Stress Analysis 2 examples 42 Example: Torsion find max shear stress for the three cross-sections: a, b and c T = 4.1 N-m = 4,100 N-mm a. Circular w/ dia = 10 m b. Square w/ side = 8.86 mm c. Hollow w/ od = 12.8 mm and id = 8 mm 43 Also see HO: Comparison of Torsion Elements, also overhead fabricated beam Shear and Moment diagrams: V w ( x ) dx M V ( x ) dx Do not get actual equations, good if just after Vmax and Mmax 44 Example: Draw Shear & Moment diagrams for the following beam 12 kN 8 kN A C D B 1m RA = 7 kN 3m 1m RC = 13 kN 45 12 kN 8 kN A C D B 1m 3m 8 7 V 1m 8 7 -15 (kN) -5 7 M (kN-m) 2.4 m -8 46 Example: Beam w/ Concentrated Moment: 47 Also see HO: Simple Beam with Uniform Load, Load-Shear-Moment Relationships Beam Bending Stress: The Flexure Formula: Internal bending moment, lb-in Max bending stress, psi s max Mc I Or in general: Distance from NA to outer fiber, in Moment of inertia, in4 s My I 48 Examples: • Find maximum moment • Find area properties, I and c • Calculate stress See HO: Bending Stress Concepts 49 WHERE IS BENDING STRESS MAXIMUM??? Answer: •Outer surface (furthest away from Neutral Axis) •Value of x along length where moment is maximum!! 50 51 52 53 Beam Shear Stress: See HO: Shear Stress Calculations in Beams Internal Shear (lb) t VQ First Moment of area (in3) at point of interest It Moment of inertia of entire cross section (in4) Thickness of crosssection at point of interest (in) Q y ' A ' 54 55 56 Find: Max Shear and Bending Stress: 1.93” 57 See HO: Stress Analysis 1 Examples, Steel Beam Selection, Steel W-Shape Selection Data Combined Loading: • Look at each load individually and solve for stress at a given point due to that load. • Repeat for all loads. • Add like stresses • Summarize stresses on an initial stress element. 58 Example: Combined normal stress – find stress in horizontal portion: 59 Example: Combined normal stress – find stress in horizontal portion: Reduce to simple cantilever! 60 Ultimate Combined Loading Problem!! 61 62 63 64 Final Concept: Beam Deflection – Superposition: No solution for this case Known case from App C Known case from App C 65