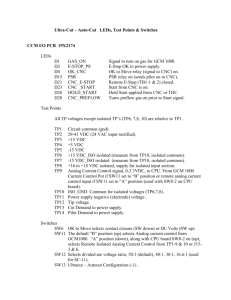

I/1 - ISC Control

advertisement

FUNDAMENTOS DEL CONTROLADOR PROGRAMABLE 1 ¿QUE ES UN CONTROLADOR PROGRAMABLE? OUTPUTS ENTRADAS PROGRAMMABLE CONTROLLER CR • A solid state device that controls output devices based on the status of the inputs, and a user developed program. • Originally developed to directly replace relays used for discrete control. 2 INPUT DEVICES • Pushbuttons • Selector Switches • Limit Switches • Level Switches • Photoelectric Sensors • Proximity Sensors • Motor Starter Contacts • 120 VAC • 240 VAC • 12 VDC • 24 VAC/VDC • TTL • Relay Contacts • Thumbwheel Switches 3 OUTPUT DEVICES • Valves • Motor Starters • Solenoids • Control Relays Relays • 120 VAC/VDC • 240 VAC/VDC • 24 VAC/VDC • Alarms Triac • Lights • 120 VAC • Fans MOSFET • Horns • 24 VDC 4 Inside a PLC Communications I n p u t High Voltage Isolation Barrier C i r c u i t s Central Processor MEMORY O u t p u t C i r c u i t s Isolation Barrier CR High Voltage data program Low Voltage AC Power Supply 85-264 VAC, 50/60Hz or DC Power Supply 5 PLC’s Come in a Variety of Sizes... Micro – Typically less than 32 I/O Small – Typically less than 128 I/O Medium – Typically less than 1024 I/O Large – Typically greater than 1024 I/O 6 And a variety of shapes/configurations Packaged Packaged with expansion Modular (rack less) Modular (rack based) Distributed 7 Packaged PLC Power supply, Inputs, Outputs and Communication port are enclosed in a single package. INPUT and OUTPUT devices are wired individually to the packaged controller. Motor M1 O/3 OUTPUT OOOO OOOO OOOO Stop INPUTS I/Ø I/1 Start 8 Packaged PLC with Expansion Base is identical to the standard Packaged PLC, but it also has the ability to drive additional I/O. The most common form of expansion is a block of I/O that uses the same base, or makes use of different types of expansion “modules”. Connections between the base and the expansion device is either direct (mating connector), or by using a wired approach (ribbon connector is very common). OOOO OOOO OOOO 2 Slot Expansion Chassis 9 Modular PLC’s (The Ultimate in Flexibility) Mix N Match Components – Processors, Power Supplies and I/O are plugged into a rack or chassis – Available in Small, Medium, and Large platforms – Flexibility results in higher costs when compared to packaged Modular PLC’s are either rack based or are rack-less Allen-Bradley SLC-500 and PLC 5 are modular PLC’s Processor RUN indicator Processor FLT indicator SLC 5/03 CPU RUN FORCE FLT DH485 BATT RS232 RUN REM PROG Force I/O indicator DH-485 Port status indicator Battery status indicator RS-232 Port status indicator DH-485 Port connection for programming terminal Keyswitch RUN, REM, PROG OUT 0 IN 0 RS-232 Port for programming terminal Power Supply Output Modules 10 Input Modules Modular Rack-Less PLC’s (The Ultimate in Flexibility) Identical in functionality to rack based PLC’s Typically not as robust (packaging) Typically found on “smaller” (small and medium) sized PLC’s. Will likely become the prevalent form of packaging in the future. 11 Distributed Rely on communications for EVERYTHING All I/O is connected to the processor through a “High Speed” data link. Typically found on “larger” (medium and large) PLC’s. For certain applications this type of form factor is very advantageous. Usually higher cost for hardware, but much lower cost for system integration. 12 Typical PLC Application Motor Solenoid 1 Solenoid 2 Ingredient A Ingredient B Sensor 1 Sensor 2 Solenoid 3 13 Operation of Mixer (Defining the Outputs) Solenoid 1 On = Sol 3 is off, and Motor is off, and Sensor 2 is off, and Auto Switch is on Off = Sol 3 is on, or Motor is on, or Sensor 2 is on Solenoid 2 Motor Solenoid 1 Solenoid 2 Ingredient A Ingredient B On = Sol 3 is off, and Motor is off, and Sensor 2 is on Off = Sol 3 is on, or Motor is on, or Sensor 1 is on Motor Sensor 1 On = Sensor 1 is on, and Solenoid 2 is off, and Solenoid 1 is off Off = Solenoid 3 on Sensor 2 Solenoid 3 Solenoid 3 On = Sol 1 is off, and Sol 2 is off, and Motor has run for 30 sec. Off = Solenoid 3 has been on for 60 sec. 14 Input Wiring Isolation Barrier Terminal Block Input Devices 1 2 3 L1 L1 4 5 6 7 8 P L C 9 L2 10 COM 15 Output Wiring Isolation Barrier CR Terminal Block OUT 1 OUT 1 Output Devices L1 L2 OUT 2 P L C OUT 2 OUT 3 OUT 3 L1 L2 OUT 4 OUT 4 OUT 5 OUT 5 OUT 6 OUT 6 16 PLC Operating Cycle START Housekeeping Input Scan Program Scan Communications Output Scan 17 Ladder Logic Concepts Read / Conditional Instructions Start (Rung #1) || () || || Write / Control Instruction || || |/| () |/| () |/| () |/| () || End (Rung #5) || 18 Ladder Logic Concepts Input Instructions Output Instruction || |/| () T T T Logical Continuity || |/| () T F F No Logical Continuity 19 Logical AND Construction IF input 004 AND input 005 have power THEN energize output 0 I/4 I/5 O/0 || || () Off 20 Logical AND Construction IF input 4 AND input 5 have power THEN energize output 0 I/4 I/5 O/0 || || () T T T On Logical Continuity 21 Logical OR Construction IF input 4 OR input 5 have power THEN energize output 0 I/4 O/0 || () Off I/5 || 22 Logical OR Construction IF input 4 OR input 5 have power THEN energize output 0 F I/4 T O/0 On || () I/5 Logical Continuity || 23 Logical OR Construction IF input 4 OR input 5 have power THEN energize output 0 I/4 T O/0 || On () Logical Continuity I/5 F|| I/4 F O/0 Off || I/5 () Logical Continuity T|| 24 Complex Construction I/4 I/0 I/1 I/9 I/10 O/0 || |/| || || || () I/5 I/1 I/7 I/8 || |/| |/| |/| I/2 I/3 || || I/11 I/1 |/| || 25 Input Instructions - XIC, XIO INPUT Input Push Button The status of the instruction is If the data file bit is XIC Examine if Closed XIO Examine if Open -| |- -|/|- Logic 0 False True Logic 1 True False 26 Output Instruction - OTE || |/| () T T T OTE Output Energize -( )- Rung State Status Bit Output Terminal TRUE ON ENERGIZED FALSE OFF De-energized Output Pilot Light OUTPUT 27 Putting it all Together SLC 5/03 CPU RUN FLT INPUT OUTPUT OUT 0 DH485 BATT RUN INPUT FORCE RS232 REM PROG IN 0 IN 0 OUT 0 || () 28 Addressing Example L1 PB1 LS1 L2 FS2 SOL6 L1 L2 I:1/1 I:1/2 I:1/3 || DEVICE ADDRESS PB1 I:1/1 LS1 I:1/2 FS2 I:1/3 SOL6 O:3/1 || || O:3/1 () 29 Relay Logic to Ladder Logic PB1 LS1 PB2 LS2 SOL2 CR3 LS3 I:1/1 I:1/2 O:3/0 || || () I:1/3 I:1/4 B3/0 || || () I:1/5 CR3 |/| LS4 || M1 B3/0 I:1/6 O:3/1 |/| || () INPUT Address Assignment: PB1- I:1/1 PB2- I:1/4 LS1- I:1/2 LS2- I:1/3 LS3- I:1/5 LS4- I:1/6 OUTPUT Address Assignment: SOL2- O:3/0 M1- O:3/1 30 SOURCING vs. SINKING The Mystery... 31 SOURCING vs. SINKING DC I/O (General) +VDC + DC Power Supply DC COM 32 SOURCING vs. SINKING DC I/O (General) SOURCING Pushbutton SINKING Pushbutton +VDC + + DC Power Supply DC Power Supply - DC COM 33 SOURCING vs. SINKING DC Inputs Field Device + IN1 DC Input Module DC Power Supply - +VDC DC COM + DC Power Supply DC Input Module Field Device IN1 34 SOURCING vs. SINKING DC Outputs +VDC +VDC OUT1 DC Output Module + Field Device DC Output Module + DC Power Supply - DC Power Supply Field Device OUT1 DC COM DC COM 35 RULES F Field devices on the positive side (+VDC) of the field power supply are sourcing field devices. F Field devices on the negative side (DC COM) of the field power supply are sinking field devices. F Sourcing field devices must be connected to sinking I/O cards and vice versa. F Sinking field devices must be connected to sourcing I/O cards and vice versa. 36