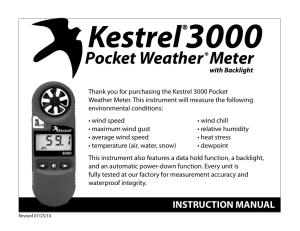

Lean Development at Kestrel

advertisement

ROADWAY DEVELOPMENT “TEMPO” LEAN AT KESTREL Rod Pike Rod Graves Superintendent Development Gateroads Development Coordinator TO IMPROVE IS TO CHANGE, TO BE PERFECT IS TO CHANGE OFTEN Sir Winston Churchill 20 year old mine. Highest profit returning business for Rio Tinto Coal Australia. We have a young, energetic and mature workforce. Tony Lennox had a focus on “good reputation” as a measure of success and good reputation is built on principles and actions. Lean Thinking is based on good principles and actions. Farthing West has been assisting us to implement Lean at Kestrel. Three areas of influence: People Behaviour - involvement in problem solving (ideas and actions) Process Users - Standardise and improve processes (end users) Equipment Processes and maintenance. Its all about the people Developing Worker Problem Solvers. BACKGROUND Kestrel Mine KESTREL – A MINE TO BE PROUD OF 8 7 6 0 Oaky North Newlands Northern Beltana / Blakefield South Mandalong Crinum East Kestrel Ulan North Wambo Oaky Creek No1 Moranbah North Grasstree Broadmeadow Angus Place Dendrobium Ravensworth North Goonyella West Wallsend Appin / Appin West Ashton Springvale West Cliff Carborough Downs Baal Bone Austar Metropolitan United Integra Tahmoor Bundoora NRE Wongawilli Million ROM tonnes Kestrel - One of the top producing mines in Australia And we do it with old equipment Jul 2009 Jun 2010 10 9 Kestrel Top Three Slide Coming from Robyn Ryan 5 4 3 2 1 Development Longwall ( Kestrel Longwall) And we are working hard to make it safer Source: Queensland Mines and Quarries Safety Performance and Health Report 2008-09 SAFETY COMPARISONS Kestrel – the best safety record in Australia. In spite of more support, greater cross grades (now 1:11), Typically weaker roof (less than 10 mpa) and high water intakes 8.5 18 8.0 16 7.5 14 7.0 12 6.5 10 6.0 8 5.5 6 Pillar Cycle Time in Days average roof support density MG310 MG309 MG308 MG307 4.0 MG306 0 MG305 4.5 MG304 2 MG303 5.0 MG302 4 average roof bolts per metre 20 MG301 average days per pillar Pillar Cycle Time vs. Prim Roof Support Density J COMBINED OVERVIEW Kestrel – Pillar cycle times improving. OUR IMPROVEMENT TO DATE WORKER PROBLEM SOLVERS Overview There are 3 documents that make up the suite of tools for the panel advance : • The Overview • Detail Cards • Check Lists Note it is the intent to incorporate the trigger for issuing all documents onto the panel sequence plan on the Lean Story Board. Detailed Card Check List PANEL ADVANCE TOOLS 3 Key Documents Teams / parallel tasking Manning Activity number for reporting Summary of activity Tools / materials required Reference for details Time in blocks of 30 mins Vehicle READING THE OVERVIEW Overview Card The team breaks up to do individual tasks STANDARD WORK CARDS Teams Colour Manning, vehicle and expected time Written in by Team Leader Read the card and Do a Take 5 Detail on each activity Activity number for reporting Reference Name Time activity began – written in by team leader Expected elapsed time at end of this task When management (ERZ controller/supervisor, coordinator, checks on progress the focus is on learning and improving. If progress is lagging what are the root cause issues? superintendent etc) FRONT OF STANDARD WORK CARDS Front of Detail Card Version and Date of last revision Tools / Material needed Sketch / picture Colour legend Team leader should provide feed back on the detail - times – sequence – errors in instructions - omissions in instructions – safety improvements – suggested new techniques – engineering mods etc REAR OF STANDARD WORK CARDS Rear of Detail Card KAMISHIBAI CARD AUDITING FLITTING ROAD CLEANING Face Road – wet and wheel rutted Place Dry Coal or stowage to start cleaning Note if conditions are wetter tip the muck from the bucket further forward over the heap TECHNIQUE TO ROLL THE MUCK Roll the muck heap and tip Face Road – wet and wheel rutted Tip load CLEAN FROM DRIVERS SIDE TO OFF SIDE Start on Driver’s side and work across heading STANDARD CUTTING HEIGHT HORIZON CONTROL TOOLS Tilt table with level attached? Guide to site seam profile? 21 STANDARDISED SUPPLY LOCATIONS IMPLEMENTS LEAN INFORMATION CENTRE In spite of more support, greater cross grades (now 1:11), weaker roof (less than 10 mpa) and high water intakes 8.5 18 8.0 16 7.5 14 7.0 12 6.5 10 6.0 8 5.5 6 5.0 4 Pillar Cycle Time in Days average roof support density MG310 MG309 MG308 MG307 MG306 MG305 MG304 MG302 0 J 4.5 KME is targeting more improvement. A 10 day pillar cycles. 4.0 MG303 2 average roof bolts per metre 20 MG301 average days per pillar Pillar Cycle Time vs. Prim Roof Support Density COMBINED OVERVIEW Kestrel – Pillar cycle times improving. 5% potential improvement from longer pillars MODELLING LONGER PILLARS AND FASTER WHEELING KME – longer pillars and faster wheeling. 307 308 309 307 Time to First Coal is averaging in excess of 4 hours per shift after allowing for Panel Advances, mobilisation and Maintenance days. Typical best times are about 1 hour 20 mins 308 309 TIME TO FIRST COAL Comments 307 In the order of 2.2 days per 28 days are lost for meetings pass and training - the morning meeting accounting for a significant portion of this time 308 309 MEETINGS / PASS / TRAINING Comments 307 1.3 to 2.1 days per 28 days are lost with road cleaning. This time probably understates the problem. 308 309 ROAD WORKS Comments CUTTING TIME Presently Only 6 days cutting every 28 days Getting the crew away on time Having the transports from pit bottom to the panels pre started Controlling meeting times Using between shifts and cribs to clean roads etc Concentrating on horizon control to reduce the need to clean roads Having tradesmen stay at the face to prove that the machine is producing correctly Train outbye workers to assist in manning the miner during one of the two crib breaks Staying at the face to cut till the end of the shift Commence planning for overlapping shifts to improve maintenance window utilisation CUTTING TIME 34 HOUR PER WEEK TO 50 HOURS Multiple small steps PILLAR CYCLE MODELLING MORE HOURS Focusing of roster issues – 30% improvement OUR IMPROVEMENT TO DATE AND OUR TARGET PEOPLE / PROCESS / PERFORMANCE 6 Mths Now Past THE GOAL IS ZERO The Goal is Zero Success with Pride 13 April 2015 36