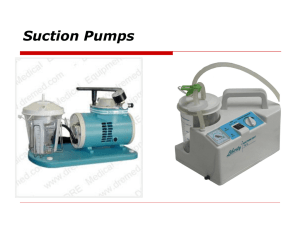

Large Vs Small Eye Impeller Design

advertisement

FSRUG Feedwater Systems Reliability Users Group (Jan 2012) San Antonio, TX SGFP Minimum Flow Operations – Impact on Reliability Presenter: Art Washburn, P.E. FSRUG • ICE BREAKER FSRUG TOPICS • • • • • • • • • • • • • • Two Rules to Get You Home Minimum Flow Protection – WHAT and WHY? Minimum Flow Operation - Problems Minimum and Maximum Flow Rates Minimum Flow Energy Levels Calculate Recommended Minimum Flow Rate Guide for Minimum Flow Operation of Pumps Recirculation - Large vs. Small Eye Impeller Design Predicted Performance Curve for Replacement Feedwater Pump Recirculation – Affect on Part Flow Operation and Corrected by Computational Fluid Dynamics (CFD) Analysis Common Discussions Between User and Pump Supplier Using Minimum Flow Protection for Discharge Piping Overpressure Protection Minimum Flow Protection – Why ? Source References FSRUG Two Rules: FSRUG Two Rules: Rule #1 – Make Conservative Decisions FSRUG Two Rules: Rule #1 – Make Conservative Decisions Rule #2 – Maintain Design Control FSRUG Two Rules: Rule #1 – Make Conservative Decisions Rule #2 – Maintain Design Control Plant Priorities: FSRUG Two Rules: Rule #1 – Make Conservative Decisions Rule #2 – Maintain Design Control Plant Priorities: 1. Nuclear Safety FSRUG Two Rules: Rule #1 – Make Conservative Decisions Rule #2 – Maintain Design Control Plant Priorities: 1. Nuclear Safety 2. Legal Requirements FSRUG Two Rules: Rule #1 – Make Conservative Decisions Rule #2 – Maintain Design Control Plant Priorities: 1. Nuclear Safety 2. Legal Requirements 3. Efficiency FSRUG Minimum Flow Protection – WHAT and WHY? - Assure Shutoff Head (zero flow) Operation Does Not Occur to Protect Pump from Catastrophic Damage - Extreme Minimum Flow (Unacceptable Temperature Rise) - Excessive Vibration (Damaging to Equipment) - Minimum Flow Path Recirculation Back to Pump Suction to a Large Volume Tank (Deaerator, Condenser) - Minimum Flow Controlled by Valve, Orifice Assembly - Main System Pump Suction Flow Velocity (8-10 FPS) - Main System Pump Discharge Flow Velocity (18-20 FPS) - Minimum Flow Piping Velocity (25-30 FPS) FSRUG Minimum Flow Operation – Problems - Pump Oversized for Application - Inlet Eye Diameter (too large, not optimum) - Head per Stage excessively high (OEM Pumps from 1970s) - Operating Strategy Changes since original Plant Specification - Minimum Flow Rate (thermal protection vs. continuous minimum flow rate) FSRUG Minimum and Maximum Flow Rates Recommended flow rate ranges for minimum and maximum, continuous and short-term, operation. From Gülich, Centrifugal Pumps. Specific Speed, ns ns = (n x Q1/2)/(H3/4) nq = ns x 0.01936 Suction Specific Speed, nss nss = (n x Q1/2)/(NPSHR3/4) FSRUG Minimum and Maximum Flow Rates FSRUG Minimum and Maximum Flow Rates FSRUG Minimum and Maximum Flow Rates Ref. ISO/CD 10816-7:2004(E) FSRUG Minimum Flow Energy Levels • • • • • • • • • • • • • The following criteria has an effect on determining minimum flow rates: Specific Speed (Ns) Suction Specific Speed (Nss) Energy Level Vibration / Pulsation Requirements Service Hours of Operation Pumpage Temperature Rise – Vapour Pressure Ratio NPSHA to NPSHR Impeller Material Impeller Design Lip Clearance Normal Duty Energy Level Pumps FSRUG Minimum Flow Energy Levels • "Normal Duty" Energy Level for Pumps • "Heavy Duty" • "High Energy" (API-610 - greater than 650 FT/STAGE and greater than 350 HP/STAGE) FSRUG Calculate Recommended Minimum Flow Rate SGFP – Sulzer 16 x 18 x 17 CD 1 Stage, 5200 RPM FSRUG Figure 1 - Guide for Minimum Flow Operation of Pumps FSRUG Application Notes for Figure 1 1) The minimum flow values given are for continuous operation. Continuous operation is considered as more than 2-hours in any 24 hours of operation. 2) For intermittent operation, reduce the minimum flow values given by 10 percentage points. 3) The minimum flow values given are for suction specific speeds (Nss) less than 10,000. Above 10,000 Nss, then increase the values given by 2 percentage points for each 1,000 Nss greater than 10,000 Nss. 4) The minimum flow values are percentages of flow at Best Efficiency Point (B.E.P.) flow taken as 100%. 5) Specific Speed (Ns), Suction Specific Speed (Nss) and head per stage are determined at best efficiency point for the actual impeller trim performance. 6) For multistage pumps, use the Specific Speed (Ns), Suction Specific Speed (Nss), and the head per stage of the first stage impeller. 7) Specific Speed (Ns) and Suction Specific Speed (Nss) for double suction impellers are based on 50% of total flow. FSRUG Calculate Recommended Minimum Flow Rate SGFP – Sulzer 16 x 18 x 17 CD 1 Stage n = 5,200 RPM Q = 20,000 GPM @ BEP H = 2,300 FT/STAGE @ BEP NPSHR = 190 FT @ BEP ns = (n x Q1/2)/(H3/4) = (5200 x 20,0001/2)/(23003/4) = 2200 nss = (n x Q1/2)/(NPSHR3/4) = (5200 x 10,0001/2)/(1903/4) = 10,000 Min Flow = (0.60)(20,000) = 12,000 GPM FSRUG Recirculation – Large Vs Small Eye Impeller Design Suction and Discharge Recirculation occurs at off peak (low flow) conditions. The turbulent mixing action due to suction or discharge re-circulation leads to surging, pulsations, vibration, and noise FSRUG Recirculation – Large Vs Small Eye Impeller Design • Recirculation & Cavitation Damage • Large Eye = High Nss (suction specific speed) FSRUG Predicted Performance Curve for Replacement Feedwater Pump FSRUG Recirculation – Large Vs Small Eye Impeller Design Large eye NPSH performance test, notice the unstable high vibration at low flows. NSS = 17,000 Eye Diameter = 7.38” (Large Eye) 6 x 10 x 14 CD FSRUG Recirculation – Large Vs Small Eye Impeller Design FSRUG Vibration Level Veff (10-10-1000 Hz) / mm.s-1 (RMS) Recirculation – Large Vs Small Eye Impeller Design; Pump Vibration Levels ‘Large eye’ 4 vanes 96.4% Max.Dia. ‘Small eye’ 5 vanes 96.4% Max.Dia. Slide shows the difference between the two impeller designs in vibration levels. Flow Rate / gal (UK)/Min Permissible Vibration Limit FSRUG Recirculation – Large Vs Small Eye Impeller Design Stall ring design is a temporary fix, to have the same influence as the small eye design on the pump suction performance, note the B.E.P will not be repositioned with this fix FSRUG Recirculation – Large Vs Small Eye Impeller Design Equation for Optimizing Eye Diameter: Eye Diameter (I.D.) = [(51.27)(Q/N)^0.666 + (Dia Shaft)^2]^0.5 FSRUG Recirculation – Affect on Part Flow Operation and Corrected by Computational Fluid Dynamics (CFD) Analysis Closed Impellers typically are lift set based on total mechanical endplay, and thermal growth. The location of the impeller to volute cutwater on discharge and suction can affect suction and discharge recirculation. FSRUG Recirculation – Affect on Part Flow Operation and Corrected by Computational Fluid Dynamics (CFD) Analysis FSRUG Recirculation – Affect on Part Flow Operation and Corrected by Computational Fluid Dynamics (CFD) Analysis FSRUG Recirculation – Affect on Part Flow Operation and Corrected by Computational Fluid Dynamics (CFD) Analysis FSRUG Common Discussions between Utility and Pump Supplier for Replacement Pump or Repaired Pump: • Continuous Minimum Flow Required by Specification vs. Existing Limitations of Minimum Flow Piping Size • Vibration Limits Required by Specification (recent limits are more stringent) • Demands to Guarantee Mechanical Performance (Vibration) on Test Stand and in Field FSRUG Using Minimum Flow Protection for Discharge Piping Overpressure Protection Common on Heater Drain Pumps Be Aware When Rerating as Part of EPU FSRUG Minimum Flow Protection – Why ? - Shutoff Head Operation FSRUG SOURCE REFERENCES: • Centrifugal Pumps: Design & Application, Lobanoff and Ross (practical application) • Centrifugal and Axial Flow Pumps, Stepanoff (theory) • Centrifugal Pumps, Gülich • Vertical Turbine, Mixed Flow & Propeller Pumps, Dicmus • Centrifugal Pump Handbook, Sulzer • Pump Handbook, Karassik • Centrifugal Pump Clinic, Karassik • Centrifugal Pumps Selection & Operation, Karassik • Centrifugal Pumps, Karassik FSRUG • ICE BREAKER FSRUG THE (HAPPY) END QUESTIONS ?