PRESENTATION TITLE Place Sub-heading here

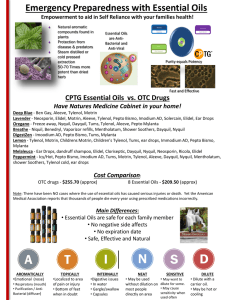

advertisement

Committed to Go Green Illinois MBA Global Consulting Program ANGOLA “The very essence of leadership is that you have to have vision. You can’t blow an uncertain trumpet.” Theodore M. Hesburgh Nomusa Gumede Super Faces Team Leader currently studying Chemical Engineering Project Team Siphelele Ngema Information Technology Lizeka Mpetha Maritime & Shipping Nomusa Gumede Chemical Engineering Nhlakanipho Dlamini Physio Therapy Sakhile Gumede Chemical Engineering Nonkululeko Mntambo Bsc in Maths & Statistics Discussion Points o Project scope & Motivation o Overview of Tasks o Basic Process Method o NEXT STEPS o Questions Project scope Development of a business plan for entrance into the used oil recycling market and the construction of a pilot plant. Elegant line Chemicals is committed to going green; the objective of this project is to implement reduction of the disposal of used oils to the environment thus reducing negative impacts to the environment. Execute a technical process which will be economical, safe, easy to carry out and environmentally friendly. Convert these used oil to by-Products such as fertilizer and further purification of water from the oils. Government and Private agricultural sectors are the main target market for these recycled oils. Develop a relationship with Angola in the recycling of oil since it is available in greater quantities. Importing and exporting of the manufactured products from oil byproducts. Motivation Expanding the business scope of Elegant Line Chemicals is the fundamental objective for this project and can be expanded utmost to describe the nature of the project. Used cooking oil is the single largest non-watery liquid waste stream in most countries in the world. During use, oil becomes contaminated with many substances that are hazardous to human health and environment. Kwa-Zulu Natal being one of the provinces with poor management of used cooking oil which results in damage to the environment and human health. Hence the next objective is to eliminate damage to the environment and work together with other organizations for sustainable development. Remote the collection of used oils. Create awareness in the mind of the public that used oil is a hazardous but a recyclable resource. Develop and implement an equitable environmental incentive for collections in outlying areas. Influence the behaviour of customers in their handling and disposal of used oil through effective educational and marketing campaigns. Undertake a pilot study of oil recycling. Consider investments in improving the handling of various used oil containers at collector and bulking facilities to increase volumes collected. The collected oil be treated by centrifuging and filtration processes. Companies such as Transnet and Metrorail, Airports like King Shaka and Restaurants are the main sources of used cooking and engine oils. Government and Private agricultural sectors FEATURES OF SUSTAINABLE DEVELOPMENT BEING: Continual Improvement: - Company level - Industry level Meet and go beyond legal and regulatory compliance WE AIM TO CONTROL ENVIRONMENTAL IMPACTS • Pollution • Use of raw materials • Emissions to land, water, and air HEALTH IMPACTS ON WORKERS AND THE PUBLIC • Re use of unthreaded cooking oil • Exposure on engine oil IMPACT ON SAFETY OF WORKERS AND THE PUBLIC Remote the collection of used oils. Mentor an innovative youth One of the many challenges our country has is the lack of innovative projects for youth empowerment. Elegant Line Super Faces is such a project which will help groom the talents and make use of the knowledge gained from schools of young people in practice. To Instil and improve entrepreneurial skills of the youth. To provide national and international exposure on doing this project. To improve communication and leadership skills and to boost confidence. It is Albert Einstine who said “The only thing that interferes with my learning is my Education”. Overview of Tasks SOURCES OF USED ENGINE OIL QUANTITIES TRANSNET Awaiting confirmation METRO RAIL Awaiting confirmation SAPS JOHHANESBURG Awaiting confirmation KING SHAKA INTERNATIONAL AIRPORT Awaiting confirmation ANGOLA- LUANDA 20 tons/month SOURCES OF USED COOKING OIL QUANTITIES Aladdin's Durban Flavour Bilal’s Bellow are the sample letters given to companies siness Address ice & Factory:47 Gillits Rd Unit J01 Pinemead Complex Westmead Contact Details: Telephone no : 031 – 7006463 Fax no : 031 – 7005781 Fax to Email : 086 - 6630419 Cellular no : 072 - 1503662 Email : info@elegantlinechemicals.co.za CK Reg: 2004/127244/23 VAT No: 4250219120 Motivation Letter We are a young and vibrant research and development team coming from Elegant line Chemicals looking to find used industrial (engine, brake fluid) oil from your company. Elegant Line Chemicals is a fast growing South African Registered Company (SMME) run by qualified African female professionals with skills and experience believed to make a difference in the chemical sector. It is a chemical manufacturing company with 3main lines of products namely: detergents; personal hygiene, water treatment and also suppliers of Industrial lubricants. As part of going green, the company has set out a research and development team, to research on possible ways of recycling (Domestic and or Industrial) used oils. Because, Elegant line Chemicals is committed to going green; the objective of our project is to implement reduction of the disposal of used oils to the environment thus reducing negative impacts to the environment. As part of our project, we plan on giving out certificates that will assure you that the oil is being handled appropriately. And if found otherwise we are entirely responsible for the damages caused by those oils. We look forward to working with you, and making our environment a greener place to live in. Kind regards PROPOSED PROCESS BY THE SUPERFACES Process Flow Diagram (CPS) Figure1: Process Flow diagram of CPS system Water outlet Oil Outlet Oil/water inlet to Tank V-2 Corrugated Plate Tank Sludge Removal valve Sludge Removal Valve Oil/Water Inlet Positive Displacement Pump Figure2: Schematic Diagram of CPS system PROCESS DISCRIPTION The Corrugated Plate Separator (CPS) uses gravity as a motive force, inside it contains plates stacked on top of each other with cast on spaces of 6/12 mm. the effluent flows through the plate pack of the separator, an oil droplet only needs to move upwards by a maximum of 12 mm before contacting the next plate which traps the droplet of oil and separate it from water, since it adheres to the underside of the plate and on account of specific gravity (which is lower than that of water) it moves along the plate to the apex of the corrugation ridge. Some of the major advantages of CPS system include: Can handle minimum of 300 of volumetric flow. Better treated effluent quality- removes free oil droplets 60 microns or larger. Low maintenance is required. Once installed its fully automatic. High efficiency and ability to meet environmental regulations. Economic and reliable operations. Some of the disadvantages include: Large surface area is required. Expensive oil/bottom scrappers that are maintenance expensive. Ineffective with small oil droplets or emulsified oil. PROJECT ARCHITECTURE PROJECT CASH FLOW ANALYSIS LAND AVAILABILITY AND COST FOR RECYLING EQUIPMENT PILOT PLANT STUDY FOR DEVELOPMENT OF INTERMEDIATE USED OILCOOLECTION AND STORAGE CENTRES QUESTIONS? ANSWERS NEXT STEPS BUSINESS PLAN FOR PILOT PLANT o o o o o o o o Equipment Land Conceptual Design layout Sources and quantities of used oil Customer and sale prices Staff Sources of funding Cash flow COMPLETIION OF BUSINESS PLAN THANK YOU!!