What Happens to our Waste?

advertisement

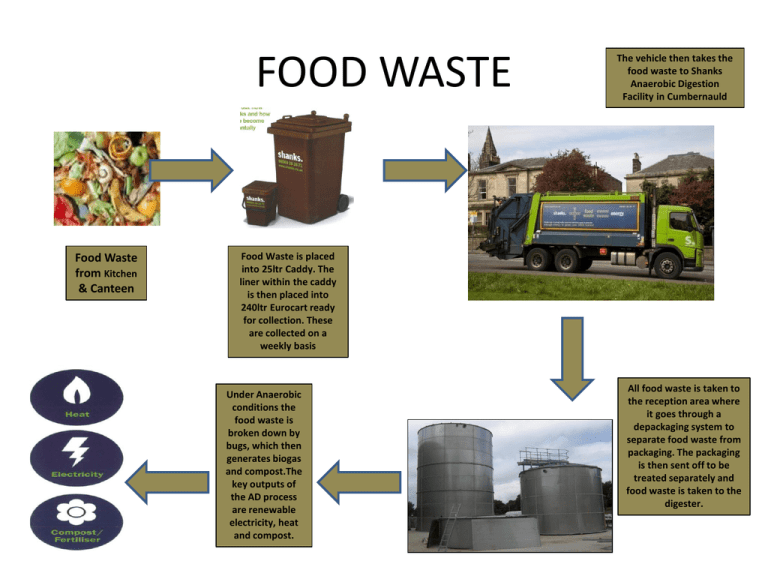

FOOD WASTE Food Waste from Kitchen & Canteen The vehicle then takes the food waste to Shanks Anaerobic Digestion Facility in Cumbernauld Food Waste is placed into 25ltr Caddy. The liner within the caddy is then placed into 240ltr Eurocart ready for collection. These are collected on a weekly basis Under Anaerobic conditions the food waste is broken down by bugs, which then generates biogas and compost.The key outputs of the AD process are renewable electricity, heat and compost. All food waste is taken to the reception area where it goes through a depackaging system to separate food waste from packaging. The packaging is then sent off to be treated separately and food waste is taken to the digester. CARDBOARD Cardboard Shanks Mixed Recycling Vehicle empties the containers and takes this back to Blochairn Materials Recycling Facility (MRF) All cardboard is placed in the Mixed Recycling Eurocarts for collection. These containers are collected Monday - Friday The separated material is baled and sold onto fully compliant companies to make recycled or partially recycled products. Once all the material is tipped at the MRF it then goes through 5 processes. Firstly the material goes through a shredder and two trommels to size the material. Secondly the material is passed through the ballistic separators which will identify material by shape. Thirdly the material is then identified by bulk density by the use of air to separate light from heavy materials. The material is then separated by the use of optical recognition. Lastly the material is passed through the picking line. PAPER Shanks Mixed Recycling Vehicle empties the containers and takes all the material back to Blochairn Materials Recycling Facility (MRF) Office Paper All paper is placed in the Mixed Recycling Eurocart for collection. These containers are collected Monday Friday The separated material is baled and sold onto fully compliant companies to make recycled or partially recycled products. Once all the material is tipped at the MRF it then goes through 5 processes. Firstly the material goes through a shredder and two trommels to size the material. Secondly the material is passed through the ballistic separators which will identify material by shape. Thirdly the material is then identified by bulk density by the use of air to separate light from heavy materials. The material is then separated by the use of optical recognition. Lastly the material is passed through the picking line. PLASTIC Shanks Mixed Recycling Vehicle empties the containers and takes all the material back to Blochairn Materials Recycling Facility (MRF) PLASTIC All plastic is placed in the Mixed Recycling Eurocart for collection. These containers are collected Monday - Friday The separated material is baled and sold onto fully compliant companies to make recycled or partially recycled products Once all the material is tipped at the MRF it then goes through 5 processes. Firstly the material goes through a shredder and two trommels to size the material. Secondly the material is passed through the ballistic separators which will identify material by shape. Thirdly the material is then identified by bulk density by the use of air to separate light from heavy materials. The material is then separated by the use of optical recognition. Lastly the material is passed through the picking line. METALS Cans & Tins Shanks Mixed Recycling Vehicle empties the containers and takes all the material back to Blochairn Materials Recycling Facility (MRF) All cans & tines are placed in the Mixed Recycling Eurocart for collection. These containers are collected Monday - Friday The separated material is baled and sold onto fully compliant companies to make recycled or partially recycled products. Once all the material is tipped at the MRF it then goes through 5 processes. Firstly the material goes through a shredder and two trommels to size the material. Secondly the material is passed through the ballistic separators which will identify material by shape. Thirdly the material is then identified by bulk density by the use of air to separate light from heavy materials. The material is then separated by the use of optical recognition. Lastly the material is passed through the picking line. GREEN WASTE Green Waste The Green Waste is firstly mulched by a large machine with teeth then made into a windrow with a batch date. Temperatures are taken every day and must read 65 degrees for 7 consecutive days to kill the bugs. Every two weeks the windrow is turned and temperatures taken. After approximately 6 months (12 turns) a sample is sent to a laboratory. Once this has been given the OK a screening process is carried out before the material is then ready for selling. Shanks vehicle will uplift the RoRo container and take this to Buchley Eco Centre