industry

advertisement

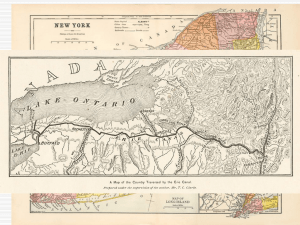

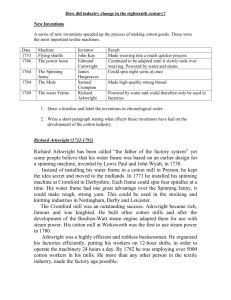

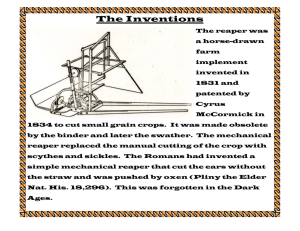

Improvements in farming equipment made it easier for smaller numbers of people to work greater areas of land. Charles Townsend suggested the idea of crop rotation rather than leaving a field fallow, this had a huge effect on farming because now land that had before sat idle produced feed for the livestock. Jethro Tull created a method of seeding that was more efficient than the random scattering of the past. His seed drill created crops that were planted in a straight row, which was easier to maintain, and used less seed to get the same results as the past. The Enclosure Movement took small parts of land and combined them into larger tracts of land that were enclosed. Due to the improvements in the farming industry this land needed fewer people to work it, leaving a great deal of the population looking for work. Inventor Cyrus McCormick introduced the horse-drawn reaper in 1831. The reaper allowed the average farmer to harvest his crops five times faster than before. The reaper replaced the hand scythe, which had been the best harvest tool available for generations. The Agricultural revolution had a great deal to do with the beginning of the Industrial Revolution. Improvements in the production of food increased the amount and quality of food available. This helped to increase the longevity of an individuals life span. With an increasing population the need for manufactured goods increased, increasing the job availability to create these goods. This increase in need led to the introduction of the Domestic System, this was a way of manufacturing wool cloth by giving families raw wool and cotton in their homes and they would spin and weave the raw materials into thread and then cloth. This was also called a cottage industry because the production was done in the families cottage. In 1769 British inventor Richard Arkwright patented his spinning frame, which spun cotton fiber into thread. Arkwright established huge cotton mills that became the models for the factory system of the Industrial Revolution. Early manufacturing employed waterpowered machinery. Water turned the paddles of a wheel, which in turn moved grinding stones or other mechanical devices. Modern water wheels, called water turbines, drive generators that produce electricity. Introduced by Richard Arkwright in 1769, the flyer spinning frame (also called the throstle or roll-drawing machine) reflects the move toward automation that characterized the Industrial Revolution. The machine is powered by the drive wheel at the bottom, drawing out the fiber into thread, then twisting it as it is wound onto the bobbins. Harnessing the power of steam marked a significant step in technology. The introduction of the steam engine led to many new inventions, most notably in transportation and industry. Steam engines transfer the energy of heat into mechanical energy, often by allowing steam to expand in a cylinder equipped with a movable piston. As the piston moves up and down (or alternatively, from side to side), an attached arm converts this motion into parallel motion that drives a wheel. Models of the steam engine were designed as early as 1690, but it was not until 70 years later that James Watt arrived at the design of the modern steam engine. Scottish inventor James Watt (1736-1819) made vast improvements to the steam engine, making it practical for large-scale industrial use. In 1764 Watt was given a Newcomen steam engine to repair. While working on the engine, he realized that it wasted energy. He eventually introduced a variety of modifications, including a separate cooling chamber for the steam that made the engine much more efficient. These huge advances in machinery created a new movement called the factory system, this brought the workers and machines together in one place to manufacture goods. Everyone worked a set number of hours and were paid daily or weekly wages. (This is the Cotton Gin that was created in 1793 by Eli Whitney. It was used to separate the sticky seeds from the cotton.) The reason that the majority of the advances were made in Britain was because they had the necessary environmental conditions, moist climate made spinning thread easier, and mineral deposits, coal and iron. In order to convert molten pig iron (crude iron) into steel with a Bessemer furnace, air must be blown through it to burn away impurities. This engraving of a steel factory illustrates the process developed by Sir Henry Bessemer in 1855 and used until the 1950s The textile industry was one of the first industries to be mechanized in 18th-century Britain. These women worked in a textile mill in Lancashire, in northwestern England. Many towns throughout Britain became manufacturing centers during the Industrial Revolution in the 18th and 19th centuries. Newcastle upon Tyne, in northeastern England, became important for steel production and shipbuilding. Division of labor is a basic tenet of industrialization. In division of labor, each worker is assigned to a different task, or step, in the manufacturing process, and as a result, total production increases. As this illustration shows, one person performing all five steps in the manufacture of a product can make one unit in a day. Five workers, each specializing in one of the five steps, can make 10 units in the same amount of time. Sir Joseph Paxton, an English landscape gardener and greenhouse architect, designed the Crystal Palace to house the Great Exhibition of 1851 in London. The Crystal Palace, constructed entirely of cast iron and glass, expanded notions of architectural beauty. As the largest structure to be built from prefabricated units up to that time, it also was a landmark of architectural design, anticipating later industrial construction. Alexander Hamilton was one of the boldest American political thinkers of his time. As the United States' first secretary of the treasury, Hamilton was very influential in setting his country on the road to industrialization. As the Industrial Revolution spread to the United States, plants such as this textile factory appeared. Soon the production of exports outpaced import of goods, and by the late 1800s America emerged as the world's largest industrial power. In 1837 the first electrical telegraph instruments were invented by Samuel Morse in the United States and by Sir Charles Wheatstone and Sir William F. Cooke in Britain. Morse sent the first public telegraph message in 1844. Pictured here is the original Morse receiving device. British engineer Richard Trevithick pioneered the use of steam power for locomotion in the 1790s and 1800s. In 1804 he constructed the first practical steam locomotive operating on a railway and demonstrated its use for hauling large loads. Locomotives from the eastern and western United States are depicted here meeting in Promontory, Utah, where crowds gathered to watch the joining of the Union Pacific and Central Pacific railroads on May 10, 1869. This first transcontinental railroad opened the West to supplies and resources from the East and served as the chief means of transportation for settlers in the West. In 1903 American industrialist Henry Ford established the Ford Motor Company, the leading manufacturer of affordable cars in the early 1900s These people work on an assembly line at Ford Motor Company. In 1913 American automobile pioneer Henry Ford instituted the assembly line process, in which each worker performs only one specialized task, in order to speed production. Andrew Carnegie made millions of dollars as a pioneer in the American steel industry. He became known for the legacy of donations— totalling nearly $350 million—that he made to various charitable causes, including education, research, and art institutions. During the Industrial Revolution, thousands of people immigrated to cities to find work. Many had to live in overcrowded tenement housing, such as this building in New York City. This photo, taken by American photographer Lewis Hine, shows an early 20th-century tenement on Elizabeth Street, in the garment-making district of New York City. Photos like this one increased public awareness of housing problems and eventually resulted in better housing conditions. During the Industrial Revolution, children were employed in factories and worked long hours. This photo by noted American photographer Lewis Hine shows young boys working at a spinning machine. Hine's photographs led to the passing of the first child-labor laws.