Energy Control Procedures Lockout/Tagout 29 CFR 1910.147

advertisement

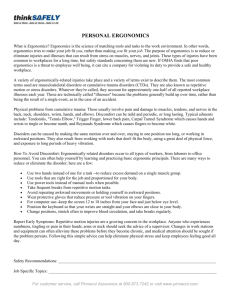

Reduction in Musculoskeletal Disorders – A Management Perspective Dan Ortiz – Principal Research Scientist Paul Schlumper – Principal Research Engineer Damon Nix – Research Engineer Georgia Tech Research Institute Safety and Health Consultation Program www.oshainfo.gatech.edu Engineering and Ergonomic Methods Define the Problem Measure the Severity Analyze the Problem Improvement Options: Generate, Evaluate, and Specify Controlled Implementation of Preferred Solution Sustain Workplace Indicators Performance deterioration Quality problems Absenteeism/turnover OSHA Logs and WC Reports Complaints of fatigue and discomfort Benefits of Ergonomic Interventions • Decreased injury risk • Increased productivity • Decreased mistakes/rework • Increased efficiency • Decreased lost work days • Decreased turnover • Improved morale Define the Problem: Musculoskeletal Disorders 2008 Musculoskeletal disorders (MSDs), often referred to as ergonomic injuries, accounted for 29 percent of all workplace injuries and illnesses Ergonomics and WMSD Costs MSDs Cost Twice the Average Workers’ Compensation Claim 0 2000 4000 6000 8000 10000 MSDs of the Back Upper Extremity MSDs Average Claim Average Costs per Claim ($) Source: Workers’ Compensation data from Insurance Companies 1993 Work Factors and Musculoskeletal Disorders Ergonomic Hazards (Risk Factors) Awkward working postures Static postures Forceful exertions Repetitive movements Pace of work Point pressures Temperature extremes Vibration Measurement of the Problem OSHA Form 300 Total Recordable and DART Rates related to Musculoskeletal disorders Checklists Observations Interviews Analyze The Problem Numerous Analysis Tools include: Job Hazard Analysis Checklists Observations Improvement and Control Control Techniques Engineering Controls Work Practices Administrative Controls Personal Protective Equipment Ergonomics Control Techniques Engineering Controls Work station design Work methods Tool design Reducing or spreading force Obtaining better mechanical advantage Ergonomics Control Techniques Task Work Practices Enlargement Work techniques Conditioning Ergonomics Control Techniques Administrative Controls Job rotation Maintenance of equipment & environment Rest breaks Increase number of employees Physical conditioning Relief personnel Medical management How Can We Increase Awareness? Association – Make it personal Organization – Good program! Concentration – Focus on task Reminders – toolbox meetings, etc. Observations Co-Workers – Buddy System, observations Control and Sustain Implement a Comprehensive Management System vs. Minimal Program Ergonomics Program Elements Management commitment & employee participation Hazard information and reporting Job hazard analysis Hazard prevention & control Medical management Training Program evaluation Minimal Program vs. Management System Minimal Program Keep 300 Form General Ergonomics Training Medical Management Program – Deal with injuries when they become really bad! Management System Strong Management Commitment and Employee Involvement Job Hazard Analyses done for each activity where employees at risk Other Worksite Analysis activities such as checklists, observations, interviews Thorough medical management program. Conservative treatment where possible Training thorough and re-visited each year. Employees “believe” in ergonomics, part of culture Continuous Improvement (ISO 14001 or OHSAS 18001) Plan Do Periodic analyses Observations Act Daily Activities Oversight and Control Functions (Inspections, observations, reminders, etc.) Check Policies Job Hazard Analysis Written Procedures – Specific, clear, easy to understand Training - Effective Refresher Training and New Employee Training Modify Procedures New Jobs – Job Hazard Analyses Go back to Plan Six Sigma-Quality Focus Define Measure Analyze Improve Control Sustain Lean (ANSI B11.TR7-2007) Setting Limits Identify Tasks Assessing Waste Reducing Waste Verifying Finishing Georgia Tech Strategy Identify team Identify problem jobs Survey Develop plan of action Prioritize activities Conduct training Develop implementation Measure results What is your culture? How do folks do things when management is not around? Why do they do it that way? What factors are present that make them do it that way? (e.g. time pressure, other incentives, etc.) Dan Petersen “Safety should be managed like any other company function. Management should direct the safety effort by setting achievable goals and by planning, organizing, and controlling to achieve them.” “The key to effective line safety performance is management procedures that fix accountability.”