Systems Level Design Presentation

advertisement

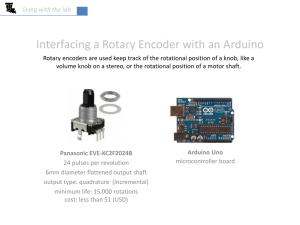

HEALTH-MONITORING OF A RECIPROCATING COMPRESSOR MSD1 – P12453 SYSTEMS LEVEL DESIGN REVIEW SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 1 AGENDA • Team and Project Member Introduction (1 min.) • Project Introduction (4 min.) • Customer Needs (5 min.) • Concept Generation (15 min) • Concept Selection (25 min) • Risk Management (10 min) • Next Steps (10 min) • Q&A (10 min) SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 2 TEAM AND PROJECT MEMBERS TEAM: Project Manager: Markus Holzenkamp (ME) Project Engineers: Cody Anderson (ME) Robin Leili-Marrazzo (ME) CUSTOMER: Dr. Jason Kolodziej, ME Department, RIT Dr. Edward Hensel, ME Department, RIT SUPPORT: Project Guide: Bill Nowak (Xerox) Faculty Champion: Dr. Kolodziej (RIT) Sponsors: Scott Delmotte (D-R) James Sorokes (D-R) Britt Dinsdale (D-R) SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 3 Reciprocating compressors Previous work Project scope PROJECT INTRODUCTION SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 4 Reciprocating compressors Reciprocating compressors use the back and forth motion of a piston connected to a crankshaft to compress the working fluid. In the case of this project we are working a single cylinder dual-action air compressor SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 5 Previous work This project is a continuation of P11452. The group installed the Dresser-Rand compressor and the first basic sensors for monitoring beginning of life characteristics SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 6 P12453 PROJECT SCOPE • Understand the current state of the compressor • Current sensors, DAQ capabilities • Operation characteristics of reciprocating compressors • Install and run ENVISION Condition monitoring system to be donated by DresserRand • Increase the current DAQ capabilities • End Goal: Design, develop, and install effective health monitoring capabilities SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 7 Table of prioritized customer needs Function diagram CUSTOMER NEEDS SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 8 TABLE OF PRIORITIZED CUSTOMER NEEDS Priority Need 1 Learn RITDAQ capabilities and propose and implement improvements in code to generate p-v diagrams, time and frequency plots 1 Propose and install possible additional sensors to measure stage pressures, stage temperature, bearing temperature (low priority) 2 Install Envision System 3 Select, install, and integrate Encoder 99 Develop future undergrad/grad labs SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 9 FUNCTION DIAGRAM Install add. sensors Measure Pressure Assistance from D-R Temp Accel Install main bearing sensor Validate Envision Results RITDAQ ENVISION Program Envision Consider Ergonomics Validate RITDAQ results Understand current capabilities ENCODER Choose an Encoder Program RITDAQ Measure accel Mount Encoder Mount Envision Measure Velocity Program Encoder Measure Crank Angle LABS Concepts needed Engineering specs: Encoder/Envision House of Quality / Pareto of engineering specs Pugh concept selection Additional sensors CONCEPT GENERATION & SELECTION SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 11 ENGINEERING SPECIFICATIONS - ENCODER SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 12 ENGINEERING SPECS - ENVISION SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 13 HOUSE OF QUALITY SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 14 PARETO OF ENGINEERING SPECS VS NEEDS SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 15 PRIORITIZED ENGINEERING SPECS SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 16 PUGH CONCEPT SELECTION FOR ENCODER SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 17 POSSIBLE LOCATIONS FOR ENCODER SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 18 ENCODER Shaft Dimensions SYSTEMS LEVEL DESIGN REVIEW Side Diameter Flywheel 2.720 in Oil Pump 0.495 in 4/13/2015 19 PUGH CONCEPT SELECTION FOR ENVISION SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 20 POSSIBLE LOCATIONS FOR ENVISION SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 21 ADDITIONAL SENSOR TABLE SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 22 POSSIBLE LOCATIONS FOR ADDITIONAL SENSORS SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 23 POSSIBLE LOCATIONS FOR ADDITIONAL SENSORS S11, S12 S13, S14 S2 SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 24 POSSIBLE LOCATIONS FOR ADDITIONAL SENSORS S9, S10 S4, S5 S6 S7, S8 S3 SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 25 RISK MANAGEMENT SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 26 SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 27 SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 28 SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 29 TOP RISKS • Trip Hazard from wires • Potential for injury • Risk to equipment • Noise in sensor signal • Cannot use data • Delay in equipment deliveries • Project falls behind schedule SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 30 MSD 1 Schedule Detail Design Enabling Action Items NEXT STEPS SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 31 MSD 1 SCHEDULE SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 32 DETAILED DESIGN ENABLING ACTION ITEMS • Markus: • Select encoder (type, make, model, specs) • Robin: • Become familiar with Envision software (how to develop screens, add functionality) Cody: Consult with Dresser-Rand on how to best install sensors (sensor type, sensor location) SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 33 Q&A SYSTEMS LEVEL DESIGN REVIEW 4/13/2015 34