“What can be measured, can be Managed”

advertisement

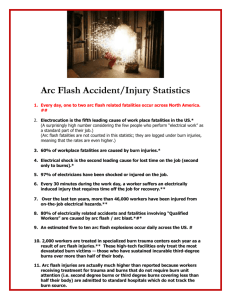

What is Technical textile?? Principally all those fabrics which exhibit Performance or some desired characteristics Performance?? HOW TO CHECK PERFORMANCE? “What can be measured, can be Managed” PETER DRUCKER Do we need Protection?? AGAINST WHAT??? Some hard facts Worldwide more than 2 million people die annually as a result of accident at work or vocation diseases. Protection against our working Environment Oil Rigs & Refineries Steel & Aluminum Furnace Fire Rescue Department Airlines and Crew and Ground Staff Shipping lines crew Racing Drivers and Support Crew Power Generation and Distribution Mining Chemical Industry Arms and Ammunition Industry Constructions Defense Forces Protection Against Hazards Protection against Fire Protection against Heat Protection against Electric Arc Protection against Molten Steel & Aluminum Protection against Cuts Protection against Fall Protection against Sudden Impact Protection against static charge Electrical Power & Distribution Need Protection against Electric Arc. Need Protection against Static charge. Need Protection against heat. What is Electric Arc Passage of Substantial electric current thru Ionized Air. Typically lasts less than a second. Extremely high radiant energy. Can Ignite or melt Normal clothing. Arc Flash Events Arc Flash happens when typically when Electrical equipment is being disconnected, tested, inspected or serviced. It can be caused by: Accidental contact with live parts. Insulation failure Close proximity of conductive subject. Power sector – Electric arc Protection • Electric Companies in USA use ASTM 1959/F for measuring the ATPV arc rating. Based on these ratings, fabrics are classified as HRC class 1, HRC class 2 or HRC class 3. •Electric Companies In Europe follow standards of Electric Arc EN 61482-12:2007-03. Specified current value is passed thru electrodes. The sample kept at 1 ft distance. Purpose is to save the wearer from 2nd Degree Burns. •EN 1149-5 is widely used as standard for measurement against static charge generation. Oil Rigs and Refineries • Need Protection against Flash Fire. •Flash fire is sudden burst of energy for less than 3 seconds. • Need Protection against heat. •Need Protection against Flamability. Possible hazards in Oil sector Flash Fire is Sudden Intense Fire caused by Ignition of Mixture of air and Flammable solid or gas It has high Temperature and short duration. High visibility needed for easy rescue. Exposure to heat and flame in close proximity. Standards for Oil Industry ISO 17493:2000 : - testing at 180C the protection against heat Expected Result – Should not Ignite, Melt or Burn ISO 15025:2000A – Put the substrate to edge ignition for 10 seconds..check Flame Spread. Expected Result – No Flaming, holing, melting and Afterglow. Ralph test – less than 50% 2nd Degree burn on flash Fire manikin test. Standards used are ISO 11612, RALPH TEST and ASTM 6413. EN 1149-3 for testing the fabrics antistatic charge dissipation properties in the Low Humidity areas. Steel & Aluminum Industry Steel and Aluminum Industry Need Protection against Molten metal( Aluminum or steel) splash. These splash can cause severe burns and can cause death. Need Proetction rfom High temperature. Need Protection from Flash Fires. Standards for Steel/Aluminum Industry EN 373 involves the checking number of molten drops on the fabric to make hole. Different levels of D1, D2,D3 defined for Aluminum. Levels E-1, E-2, E-3 defined for Steel. Different Products have to be used based on the applicable industry. EN 13034 involves checking the garment against Chemical splash. EN 11612 is widely accepted standard for protection against heat and Flamability. Construction • Protection against Dust and filth • Protection against Sharp objects • Protection against low Visibility. • Protection against Welding ,gas cutting gas cutting debris. Standards for construction industry EN 470-1 (new standard ISO 11611) for protection against molten metal spatter during welding. The standards consist of testing against Limited Flame spread (EN 532), spatters of molten metal (EN 348) Protection against Rubs, tears and cuts. Defense Forces The success of military camouflage led to the development Based on equipment of surveillance Near-IR allows technology. technology, identification modern of the personnel from surroundings in the dark. This means military camouflage also requires reflectance values in the Near- IR range that matched the expected surrounding topography. For military personnel, it is necessary to wear the appropriate clothing that attempts to minimize the contrast between objects and their environment over the NIR region in addition to the visible region. UAE Army Printed Fabric Picture captured under Visual Light Picture captured under IR Light Reflectance Values for UAE Army Wave length [nm] 700 750 800 850 900 950 1000 1050 1100 1150 1200 Beige 44.78 45.52 48.83 54.15 59.92 64.21 66.65 68.04 68.79 68.64 67.77 Lt Brown Md Brown Dk Brown 26.34 19.11 14.96 27.30 19.81 15.51 29.06 21.02 16.34 31.31 22.44 17.39 33.55 23.84 18.05 35.38 25.11 18.94 36.71 26.11 19.70 37.80 26.97 20.33 38.69 27.73 20.92 39.29 28.33 21.41 39.59 28.79 21.81 Reflectance Values for UAE Army Sample with IRR finish shows perfect disruption in NIR region( 700-1200 nm). UK Army Printed Fabric Picture captured under Visual Light Picture captured under IR Light Reflectance Values for UK Army Wavelength [nm] 700 750 800 850 900 950 1000 1050 1100 1150 1200 Lt Green 30.75 35.90 37.63 39.54 41.49 43.68 45.49 46.92 47.88 48.29 48.79 Green 8.18 21.56 29.70 32.27 34.08 36.28 37.97 39.26 40.16 40.68 41.29 Brown 4.97 6.39 7.80 9.56 11.34 12.58 13.30 13.78 14.16 14.45 14.70 Black 6.10 7.60 8.91 10.16 11.39 12.08 12.54 12.86 13.14 13.39 13.58 Current Indian Scenario Safety in Industry is not given its Due Importance. Workers working at the Blast Furnace wear cotton cloths at best to avoid flame. Construction Workers hardly have any protective belt or gear. Indian defense forces are happy with the basic camouflage. Safety standards are either derived from USA or Europe, but they are hardly followed. Accidents are hidden under the carpet to avoid claims. PPE are kept for showcase. Summarise the discussion Performance should be measured. Measurement has to be against needs. Needs of the Industry should be Expressed in terms of Values. Test methods need to be devised considering the requirements of the Industry. Required standards need to be specified against these tests. Tests and standards have to be relevant to the Industry. The strong law enforcement for the standards is the key. BIS has to play an Important role by conducting frequent meetings of Standards committee including Industry nominees. ALOK INDUSTRIES We are a new generation Textile company based in India. We offer integrated textile solutions to Global textile industry. We are having modern & vertical integrated manufacturing facilities for producing Apparel fabrics, Home Textiles, Garments & Texturised polyester yarn. We have a knits production facility also to complete our range. We initiated this Business about 6 years back and grown this business with the focused approach. Understanding the requirements of the industry and producing fabrics to suit its norma is the key of our success. We believe in constantly upgrading our selves as per the global industry norms and buyer’s requirements. ANY QUESTIONS??? THANK YOU YOGESH KALIA