Tactical Sealing Technologies, Corp

advertisement

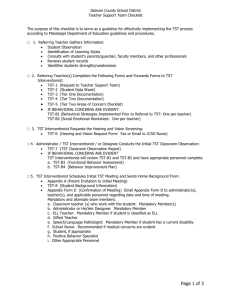

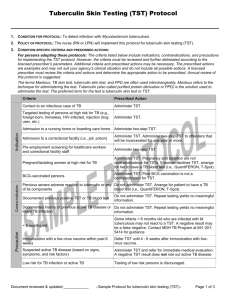

Tactical Sealing Technologies, Corp. About Us • We specialize in custom manufacturing of high performance thermoplastics, thermo-elastomers, and metal components used in many diverse industries including, but not limited to, oil & gas, pipeline, semi-conductor, mining, industrial, and automotive. • Our mission is to provide innovative sealing solutions through state of the art manufacturing technologies. • Seal design engineering available as necessary. History • Founded in 2008, Tactical Sealing Technologies, Corp. (TST) is an ISO 9001:2008 Certified Company. • The founders of TST have a combined history of over 100 years experience in the development and manufacturing of specialty products for the oil, gas, and energy industries. • TST is dedicated to producing the highest quality pressure containment components to meet or exceed customers’ expectations. Machine Center Facility/Equipment • 13000 sq./ft. high end manufacturing facility comprising of eight CNC Lathes, two CNC Mills, as well as manual lathes and mills. Additional 5000 sq./ft. expected by end of 2013. • CNC-Lathes 6" - 15" Automated Chucks 1/8" - 23" Diameter up to 40" Length CNC-Mills 2 - 40 x 20 x 20 with 4th Axis 20 x 16 x 16 with 4th Axis Manual Lathe/Manual Mill Lathe = 12"-OD x 47” Length Max Mill = 16W x 30L x 20H Thermo-elastomer Facility/Equipment • 15 presses ranging from 30 tons to 350 tons. – – – – Compression-Molding Transfer-Molding Diameters to 23" OD Bonding • Metal • PTFEs • other composites – Molded Elastomer Seat Bonding – Molded Spring Energized Seals – Post Manufacturing Coatings Inspection Equipment • Inspection equipment including Gagemaker, Rockwell, Deltronic, Fowler, & many more. Gagemaker MIC TRAC MT-3000 Services • Compression and Transfer Molding of Elastomers. • Fully Automated CNC Machining of Thermoplastics and Metals. • Inspection – 1.5 AQL Minimum • Contract Design and Engineering Support – allows us to take your project from conception to completion in house. Materials • Elastomers – FFKM, FKM, Aflas™, Nitrile, HNBR, Phenolic, etc… • Thermoplastics – Peek, PTFE, PPS, Nylon, UHMW, etc… • Metals – Stainless • 303, 304, 316, 410, 420, 17-4PH, 13-8PH, 15-5PH, NIT50, NIT60 – Aluminum • 1100, 2024, 3003, 5052, 6061, 6063, 7075 – Nickel • 400, K500, 718 – Beryllium Copper (non-toxic levels) • C17200, A25, AT (TFOO), HT (THO4), C173 – Carbon Steel • 1018 – 1026, 12L14, 1215, A105, A350 – LF2, 4130 – 4145, 4340, 8620, 9310 ™Aflas is a trade name of Asahi Glass PRODUCTS Completions • • • • Downhole Completion Seals Complete Tool Redress kits Bonded Seals Backups Valve • • • • • • • Valve Seats O-Rings U-Packing Vee Packing Float Valve Seals PTFE Bonded Seals Stem Packing Exploring/Drilling • • • • Fishing Tool Packing Jar/Shock Tool Packing Mandrel/Washpipe Packing Plunger/Swivel Packing • Liner Packers Fracing • • • • Fracing Balls Bearings Quad Ring Seals Rotary Seals Misc. Products • • • • • • • Stripper Rubbers Packer Elements Polypaks Wipers Wire Mesh Elements Wire Mesh Filters Metering Components Upstream, Midstream, Downstream Quality • TST has a Quality Management System including ISO 9001:2008 Certification. Our commitment to the QMS provides our customers with excellent customer service and an overall confidence in doing business with TST. • This QMS has been designed to provide specific direction toward ensuring that customer needs and expectations are determined, converted into requirements, and fulfilled with the aim of achieving customer satisfaction. Future • Thermoplastic Molding • Injection Molding • Developing & Testing “ED” Resistant Elastomers • Engineering Additions Benefits • Made specific to customers needs/requirements – TST will meet any design/spec set by our customers • Partnering our services – Multiple partnerships allow us to provide any service needed to get the job done • Rapid Response • 10 year minimum controlled traceability on all parts and materials • Experienced professional staff Contacts Tactical Sealing Technologies 10492 Commerce Row Montgomery, TX 77356 www.tacticalseals.com Sales Phone: 936-582-2560 Fax: 936-582-2564 Scott Ledbetter - Outside Sales sledbetter@tacticalseals.com Jeff Ford - CEO jford@tacticalseals.com Kasey Boyce - Customer Service & Expediting kboyce@tacticalseals.com Patrick Irene - QMS Manager pirene@tacticalseals.com Dana Boyce – COO/VP Marketing dboyce@tacticalseals.com General Sales sales@tacticalseals.com