Sewage_System

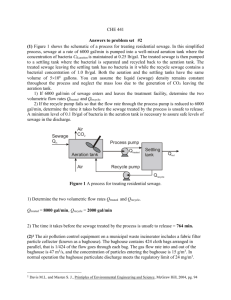

advertisement

Sewage System Analysis of the substance • • • • Unpleasant smell Corrosive Nutritious for bacteria Good environment for disease-causing bacteria Natural break down in the water • Biochemical oxygen demand (BOD) measures the amount of dissolved oxygen needed to decompose organic matter in the water through aerobic processes. This oxygen depletion can stress fish and other aquatic organisms that depend on dissolved oxygen to live. Natural break down in the water • Marine sewage contains nutrients such as nitrogen that can cause algae to grow and spread in the form of blooms. Algal blooms can block the light needed by other marine life, and if the algae decays it also uses up oxygen. Natural break down in the water • Chemical products used in holding tanks or in chemical toilets to disinfect and deodorise the sewage are also discharged when sewage is dumped into the sea. These products have the potential to be toxic to marine life. Public health Disease-causing bacteria spread by sewage: • • • • • Hepatitis A Giardia Cryptosporidium Typhoid Cholera Contact with polluted water can also cause skin infections and respiratory problems. Public health • More importantly, people who eat shellfish grown in contaminated water (especially raw or poorly cooked oysters or mussels) risk food poisoning. • Viruses, in particular, can survive for a long time in water, sediments and shellfish, and are still able to infect people. Millions of viruses are shed per gram of faeces. The law • In US and many UE countries – Discharge of untreated raw sewage is illegal anywhere within the US’ three-mile limit • In NZ - No one can discharge untreated sewage in the coastal marine area from a ship or an offshore installation unless that discharge is more than 500 metres from shore, in waters deeper than 5 metres and more than 500 metres from a marine farm or gazetted mataitai reserve, or more than 200 metres from a marine reserve. Regulations on treated sewage • The Regulations now provide for two standards of treated sewage – Grade A and Grade B. These systems produce a different standard of effluent. Grade A These are the systems that have been approved by the International Maritime Organisation (IMO) as meeting the International Convention for the Prevention of Pollution from Ships 1973/78 (MARPOL) standard of treated sewage. They are the larger, more comprehensive sewage treatment systems and they are usually fitted on larger, commercial or recreational ships. They also include systems that, when tested according to IMO criteria, meet the standard set out in schedule 6 of the Regulations. Grade B These are the systems that have been approved by the United States Coast Guard as a Type I system and are available in New Zealand. These systems are smaller, cheaper and can be installed in recreational craft. Regulations for Treated sewage discharge The discharge of treated sewage from either a Grade A or Grade B system, provided the systems are operated correctly and maintained in good working order, is allowed anywhere except within 100 metres of a marine farm (if you are a Grade A system) and 500 metres of a marine farm or a gazetted mataitai area (if you are a Grade B system). Ministry of Environment • Website of the Ministry of Environment http://www.mfe.govt.nz/publications/water/ You can find regulations and articles on the topic Legal possibilities for discharge • In the above described legal zone • Pump-out facilities at marinas (p.42of Hold it. . . We're Cleaning Up The Coast - Dealing With Sewage Safely and Responsibly on Your Boat )p.44 of the file Pump-out facilities at marinas • Standard deck connection is required It is a Standard 38 mm pipe thread inside diameter deck pump-out fitting. ( see p.45 and 30 of Hold it. . . We're Cleaning Up The Coast Dealing With Sewage Safely and Responsibly on Your Boat) p.47 and 32 of the file Conclusions: In our design we should provide possibilities for: • Holding sewage and possibly to treat it • Discharging the holding tank from deck • Discharging the tank overboard • Possibly Direct overboard discharging the toilets for small crafts, when sailing in unlimited zone System design Ignoring the portable chemical toilets (p.40) for the smallest boats, where other type facility can not be installed, there are basically three methods by which sewage can be handled and made to flow along the soil pipes: 1. Gravity system 2. Pressure Pumping System 3. Vacuum Pumping System Gravity system Like common household the waste is flushed along a relatively large diameter soil pipe by quantity of water • Each soil pipe run must have sufficient slope (trim and heel) • Water traps must be provided adjacent to the WCs • Small macerator may be fitted in each line adjacent to the WC and pipe size may be reduced • A pressure pump may also be incorporated in the unit which allows further reduction in piping size. Gravity system Pressure Pumping System In these systems the soil is moved by pressure created by a suitable displacement pump and macerator (can run against gravity) • It requires more flushing water than the gravity system • efficient non—return valves need to be fitted • the system needs to be used frequently or alternatively flushed through with clean water at regular intervals • requires periodic cleaning and dismantling of the pump in the system Vacuum Pumping System Vacuum system uses air under vacuum pressures to move the soil along the pipework to the holding tanks • The system includes a vacuum air pump which maintains a constant vacuum pressure on the holding tank (no special maintenance of the pump) • The system uses only about 1.5 litres of water and reduces the sewage volume to approximately 1/10th of that for conventional gravity toilets Vacuum Pumping System Sewage treatment Two particular types of sewage treatment plant are in use • employing chemical methods • employing biological methods Chemical Sewage Treatment • The chemical method is basically a storage tank which collected solid material for disposal in permitted areas or to a shore collection facility. • Various chemicals are added at different points for odour and colour removal and also to assist breakdown and sterilisation. • Tests must be performed daily to check the chemical dosage rates. This is to prevent odours developing and also to avoid corrosion as a result of high levels of alkalinity. • A chemical plant can be started up and shut down at will as the ship enters and leaves regulated waters. • They may however require more attention while they are in use as they are likely to use filters and screens which would need regular cleaning, and solids accumulate at a faster rate than in biological plants. Waste entering the plant is first screened to separate liquid from solids, which then pass untreated into a collection tank. The partially clarified liquid is treated with sodium hypochlorite and a small amount of flocculent. Purified effluent is then drawn through a weir in the treatment tank and pumped overboard. Treatment plant • Grade B sewage treatment system – available in New Zealand. LectraSan is an electrochemical sewage treatment unit. (p.22) • Questions to be considered: 1. Does it suit the electrical balance of the boat at any time? 2. Can the unit be acoustically insulated? 3. Can owner or crew meet maintenance requirements given by manufacturer? Electro-chemical sewage treatment • It macerates solid sewage to indiscernible particles • It oxidises it by hypochlorous acid produced by an electrochemical action with the aid of an electrode This treatment destroys most of the bacteria and the odour-causing agent Biological sewage treatment The biological system utilises bacteria to completely break down the sewage into an acceptable substance for discharge into any waters. • The extended aeration process provides a climate in which oxygen-loving bacteria multiply and digest the sewage, converting it into sludge. Biological sewage treatment • The sewage then flows into the settling compartment where the activated sludge is settled out. • The clear liquid flows to the chlorinator or to ultra—violet light, and after treatment to kill any remaining bacteria it is discharged. • The sludge must be discharged only in a decontrolled area ; [Incinerators (furnace, for burning waste) can complete the process. After use the ash box can be emptied overboard ] Design • Most popular head arrangement is manual one Make a schematic for a single head • What components should be included? • What hazards can you foresee? • How to prevent them? Questions to decide • • • • Material of the tank and pipes Volume of the tank Tank discharge pump type and size Type of the toilet