Criteria Pollutants

advertisement

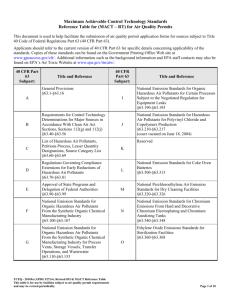

Overview of Air Pollutants and Management Strategies – Env 247 – February 24, 2011 Classification of Air Pollutants Air Pollutants Criteria Pollutants NOx, Sox, PM, CO, Ozone, Lead Mobile Pollutants CO, VOCs, NOx, Sox, Lead Health Effects Irritant, Edema, Emphysema Acid Rain Precursors Sox, NOx Emission Cap and Trade Program Air Toxics NESHAPS, HAPs, TAPs, 112r Substances Ozone Depleters CFCs, HCFCs, Halogenated VOCs Health Effects – Toxics, Mutagens, Carcinogens Permits - Title V, NSPS, NSR Standards – Threshold Emission Limits Standards - NAAQS Permits – Major Source = 10/25 tons Title V Control – Attainment, SIPs Control – MACT, RMPs Source control LAER BACT Criteria Pollutants Pollutants for which National Ambient Air Quality Standards (NAAQS) have been established: 1. 2. 3. 4. 5. 6. Particulates (PM10) Sulfur Oxides (SOx) Nitrogen Oxides (NOx) Carbon Monoxide (CO) Photochemical Oxidants (Ozone) Lead Toxic Pollutants Pollutants hazardous to health or the environment but not regulated as criteria pollutants: 1. 2. 3. 4. 5. 6. 7. 8. 9. Mercury Asbestos Arsenic Benzene Radon Vinyl Chloride Beryllium Coke Oven Emissions 188 compounds designated by EPA as “Hazardous Air Pollutants” or HAPs. 10. North Carolina has identified 105 “Toxic Air Pollutants” with acceptable ambient levels or AALs. Global Pollutants Pollutants that because of their persistence or distribution have a global impact on air quality: • Chlorofluorocarbons – Stable “freons” that once in the stratosphere breakdown Ozone. • Carbon dioxide – Major substance related to the global “greenhouse effect”. Regulation of Air Pollution Hazardous Air Pollutants - HAPs: 188 Specific compounds Definition = A substance when released to the atmosphere can cause significant harm to human health or the environment; includes Particularly or extremely toxic substances Carcinogens Mutagens Regulation of Air Pollution Hazardous Air Pollutants – Sources Major Source = Any stationary source that emits 10 tons or more per year of any single HAPs or 25 tons or more per years of all HAPs. Area Source = Any stationary source of HAPs that is not a major source. Regulation of Air Pollution Hazardous Air Pollutants – Emission Control US EPA required to list: categories of major sources, categories of area sources warranting regulations, and national emission standards. Maximum Achievable Control Technology or MACT = For a major source in a particular category – The average emission limitations achieved by the best performing 12% of existing sources or The average emission limitation achieved by the best performing 5 sources if there are fewer than 30 sources in a given category HOW HAPS AND TAPS ARE REGULATED Emission limits for major or area sources are established and regulated by air permitting process Sources (major and area) of HAPs must install MACT to meet HAP emission reduction requirements All sources of NC TAPs must comply with NC TAP regulations CONTROL OF HAZARDOUS AND TOXIC AIR POLLUTANTS NC Toxic Air Pollutants TAPS Program Compliments the Clean Air Act Program for Hazardous Air Pollutants (HAPs) Federal HAP Program is technology-based and requires Maximum Achievable Control Technology (MACT) NC TAP Program is health-based and has an acceptable ambient concentration Regulation of Air Pollution North Carolina – Toxic Air Program A health-based toxic air pollutant control program that regulates 105 air pollutants emitted from stationary sources. Emissions of toxic air pollutants must be reduced such that the resulting modeled ambient air levels are below health-based acceptable ambient air levels at the property line. Regulated facilities must submit a complete air toxic emissions report once every 3 years. NC TAP REGULATORY PROGRAM The Science Advisory Board sets an exposure limit – the Acceptable Ambient Limit (AAL) The NC Division of Air Quality (DAQ) is responsible for enforcing the AAL through air permits: The NCDAQ sets an emission limit from emission sources above which the ambient concentration will be exceeded This emission limit (rate) is called the Toxic Permitting Exemption Rate, or TPER NC TOXIC AIR POLLUTANTS Each TAP has an AAL-Acceptable Ambient Level established by a State Science Advisory Board (SAB) SAB composed of physicians, toxicologist and other scientists The AAL is the concentration limit for exposure of the public Some pollutants have hourly limits, others have daily or annual Examples HCl: Hourly Limit Carbon disulfide: 24-hour limit EtO: Annual limit Hourly = Acute irritant 24-hour = Chronic irritant Annual = Cancer causing EXAMPLE OF STEPS INVOLVED ETHYLENE OXIDE Identify all possible sources of EtO Determine the emission rate of each source. In this case – 7 EtO sterilizers - number of cycles per year - emission of EtO per cycle Obtain precise emission parameters - stack height, location - exhaust temperature, velocity, etc. Build the computer dispersion model - topography - all buildings, structures, etc. - all emission information Obtain NCDAQ approval of all modeling information Run the emission model (Aeromod) for 5 consecutive years of meteorological data. Use results of the worst-case year and must be below Acceptable Ambient Limit. Apply for air permit with emission limits AIR PERMITTING OF TOXIC AIR POLLUTANTS If facility’s emissions of any TAP are above the TPER, facility must: Perform dispersion modeling to demonstrate that the off-site concentration due to the facility emissions will be below the Acceptable Ambient Limit Submit application for air permit Maintain records to demonstrate it always operates within the emission limits of its air permit Modeling Air Toxics – Ethylene Oxide Meteorological Data Stack Parameters Temperature Exit velocity Stack diameter Stack height Constituent Emission Rate Modeled air concentration – Air model (Aeromod) expressed as a single point of maximum impact or as an isopleth EXAMPLE OF MODEL RESULTS ETHYLENE OXIDE EXAMPLE The TPER for EtO is 1.8 lbs/yr The EtO potential emissions (assumes every sterilizer runs 24/7) were estimated at 18.02 lbs/yr – Therefore: Constructed and ran computer model and applied for air permit Modeling results: - Allowable Ambient Limit (AAL) = 2.7 x 10-5 milligrams/m3 - Highest concentration = 8.47 x 10-6 milligrams/m3 - Highest concentration ~ 31% of AAL at one spot - Vast majority of area is less than 10% of the AAL Figure shows modeling results in micrograms/m3 (µg/m3) e.g. kellygreen = 0.003 µg/m3 = 0.000003 milligrams/m3 = 11% of AAL Release Prevention and Control Regulatory Actions Aimed towards Emergency Preparedness to Prevent and Mitigate Releases . Release Prevention and Control – SARA Title III Section 302 – Identification of Extremely Hazardous Substances stored, processed or otherwise used above threshold planning quantities Section 304 – Notification of reportable releases of CERCLA hazardous substances or Section 302 Extremely Hazardous Substances above reportable quantities. Section 311 – Initial report to local fire department, LERC, and SERC of hazardous substances used or stored on site. Section 312 – Annual report on the presence of hazardous substances used or stored on site Section 313 – Toxic Release Inventory: Facilities with SIC codes 20-39 who manufacture or process more than 25,00 lbs/yr or use more than 10,000 lbs/hr of listed toxic chemicals must report annual releases to the environment . Release Prevention and Control Prevention of Accidental Releases – Hazardous Substances Defined as: Any chemical listed under Section 112(r) or any other chemical which may, as a result of short-term exposures, cause death, injury, or property damage due to their toxicity, reactivity, or corrosivity. Release Prevention and Control Prevention of Accidental Releases – Section 112(r) Risk Management Planning Owners/operators of stationary sources subject to Section 112 (r) that use, store or process listed hazardous chemicals at or above designated thresholds must implement a Risk Management Program the includes An off-site consequence analysis to evaluate: A worst-case scenario and Other alternative release scenarios. Develop and maintain a 5 year release history. A Release Prevention Program. An Emergency Response Plan Release Prevention and Control Prevention of Accidental Releases – Section 112(r) General Duty Clause Owners/operators of stationary sources that produce, process, handle or store any listed substance or other extremely hazardous substance below the threshold quantity must develop and implement plans to – Identify hazards which may result for releases using appropriate hazard assessment techniques. Design and maintain a safe facility, taking steps as necessary to prevent releases, and Minimize the consequences of accidental releases.