1 - OMICS Group Conferences

advertisement

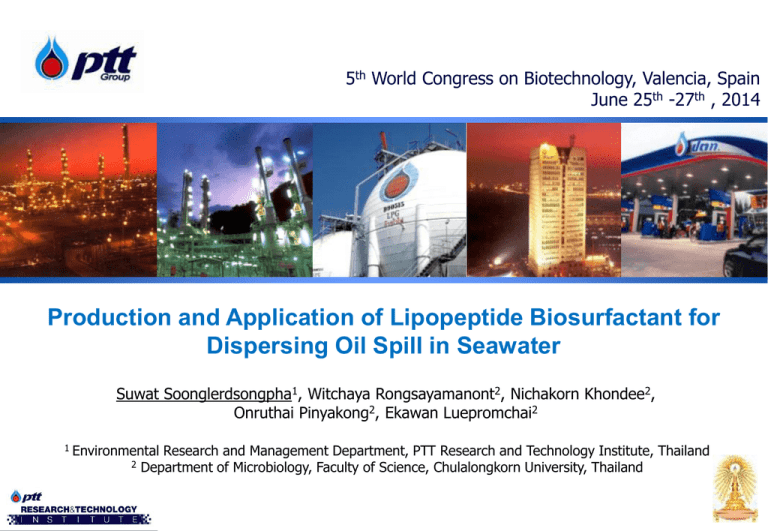

5th World Congress on Biotechnology, Valencia, Spain June 25th -27th , 2014 Production and Application of Lipopeptide Biosurfactant for Dispersing Oil Spill in Seawater Suwat Soonglerdsongpha1, Witchaya Rongsayamanont2, Nichakorn Khondee2, Onruthai Pinyakong2, Ekawan Luepromchai2 1 Environmental Research and Management Department, PTT Research and Technology Institute, Thailand 2 Department of Microbiology, Faculty of Science, Chulalongkorn University, Thailand 1 Biosurfactant Biosurfactants are surface-active biomolecules produced by microorganisms. Hydrophilic Moiety • Acid • Peptide cations or anions • Mono-, di- or polysaccharides Biosurfactant Hydrophobic Moiety • Unsaturated or saturated hydrocarbon chains • Fatty acids Hydrophilic Moiety Hydrophobic Moiety (Surfactant head) (Surfactant tail) CMC (http://www.ualberta.ca/~csps/JPPS8(2)/C.Rangel-Yagui/solubilization.htm) CMC = Critical Micelle Concentration (http://people.umass.edu/mcclemen/Group.html) 2 Biosurfactant Classification of Biosurfactants Glycolipids – Sophorolipids, Trehalolipids, and Rhamnolipids Lipopeptides and Lipoproteins Fatty acids Phospholipids Neutral lipids Polymeric biosurfactants Particulate biosurfactants Rhamnolipid Sophorolipid Trehalolipid Surfactin (Lipopeptide) http://biotechsupportbase.com/wp-content/uploads/2014/02/surfactants.png 3 Biosurfactant Advantages Non-toxic or low in toxicity Biodegradable Wastes can be used as raw materials Able to work at critical condition Wide applications Limitations Low production yield High production cost 4 Applications of Biosurfactants Biosurfactant applications 1. 2. 3. 4. 5. 6. 7. 8. Household detergent Personal care Industrial cleaner Food processing Oilfield chemicals Agriculture chemicals Textiles Others Environmental applications Soil bioremediation Oil dispersant Biosurfactant market volume share (by application, 2013) (http://www.grandviewresearch.com/industry-analysis/biosurfactants-industry) 5 Dispersant use for oil spill Blend of two or three surfactants Ex. nonionic /anionic/solvent Oil droplets Increase natural attenuation and biodegradation by microorganism. However, synthetic dispersants are usually toxic and may decrease biological activity of microorganisms. 6 Objectives Low cost substrates??? Substrates Microorganisms Biosurfactant producing Microorganisms??? Production & downstream processes Production & downstream Processes??? Biosurfactants Dispersing oil application??? 7 Scope of Experiment Isolation of biosurfactantproducing bacteria Evaluation of substrate utilization Production of biosurfactant by chitosan-immobilized cell Purification of biosurfactant by Foam fractionation and Freeze-drying Biosurfactant Characterization of biosurfactant Properties & stabilities of biosurfactant Application of biosurfactant for dispersing oil 8 Biosurfactant producing microorganisms & Substrate selection Isolation of microorganisms ดิน ทราย นา้ ทะเล นา้ คลอง ดินป่าชายเลน ี นา้ เสย ใบไม้ คล ังเก็บจุลน ิ ทรีย ์ 107 species Substrate Selection Pure substrate Glycerol Soybean oil Palm oil Crude oil Diesel Lube Microbial screening Organic waste Surface tension < 40 mN/m 58 species Slop oil Bottom glycerol High yield Low cost Waste reduction -PTT Group Use only- Bacillus sp. Highest yield GY19 9 Screening of biosurfactant-producing bacteria 107 strains Surface tension < 40 mN/m Highest yield Pure glycerol Yield Bacillus sp. 0.13 g/l GY19 58 strains 20 genus Bottom glycerol + palm oil Leu CH3 Surfactin O Glu myristoleic acid O HO NH O O NH H3C Leu CH3 O H3C N H CH3 O HN O O H N H N O CH3 O CO2H Surfactin Leu CH3 Yield 2.8 g/l CH NH 3 CH3 CH3 Val Lipopeptide biosurfactant Asp Leu Biosurfactant from pure glycerol BSF PG 10 Lipopeptide production and recovery processes Substrate Low cost substrate Waste utilization Waste from biodiesel production Production Downstream High production yield Efficient recovery and purification methods Immobilized bacteria on cheap and effective materials Foam fractionation Solvent-free method Develop Cheap, easy and effective bioprocess Bottom glycerol (10% glycerol + fatty acids and etc.) Chitosan-immobilized cells Foamate easy to use and effective for further application Foam fractionation 11 Lipopeptide production by chitosan immobilized cells in stirred tank bioreactor - Palm oil was added as precursor - Maximum lipopeptide yield 6.65 g/L Crude biosurfactant 10 9 8 7 6 5 4 3 2 1 0 Oil Glycerol 80 Cycle 1 Cycle 3 Cycle 2 Cycle 4 Cycle 5 Cycle 6 60 40 20 Remaining glycerol (g/L) Crude biosurfactant (g/L) Remainging oil (g/L) A 0 0 5 10 Time (day) 15 20 25 12 Properties of lipopeptide biosurfactant Freeze-drying Cell free supernatant Foam-fractionation Foamate Biosurfactant powder 50% lipopeptide (w/w) 70 Lowest SFT ~ 26 mN/m Concentration of foamate (%) Surface tension (mN/m) 60 1st batch production 2nd batch production 50 3rd batch production 40 30 20 10 0 0.001 0.01 0.1 1 Biosurfactant powder conc. (%, w/v)) 10 13 40 surface tension (mN/m) surface tension (mN/m) Stabilities of lipopeptide biosurfactant 35 30 25 20 15 10 surface tension (mN/m) 30 40 50 60 Temperature (C) 70 80 40 35 30 25 20 15 10 0 1 2 3 4 5 6 NaCl (%) 7 8 9 10 40 35 Surface activity was stable at 30 25 Temperature (40-100oC) 20 Electrolytes (> 6% NaCl) 15 pH 7-11. 10 2 4 6 pH 8 10 12 14 Lipopeptide toxicity tests Toxic to brine shrimp at very high concentrations Brine shrimp % survival 100 80 60 No brine shrimp survive 40 20 0 Artimia assay (Luna et al., 2013) 0.5XCMC 1XCMC 0.025 % (w/v) 0.05 % (w/v) 2XCMC 10XCMC 50XCMC (1:10 dilution) 0.1 % (w/v) 0.5 % (w/v) 2.5 % (w/v) dispersant standard Biosurfactant No toxicity to plant seedlings Water Control Biosurfactant SDS seawater No toxicity to PAH-degrading bacteria Biosurfactant LS9TH SDS 15 Lipopeptide based dispersant lipopeptide conc. • Varying from 0.25-10 % (w/v) Seawater Oil 20 µl Petroleum type • Oman light crude oil • Arabian light crude oil • Diesel oil • Fuel oil BSF 10 µl 0% oil displacement 100 % oil displacement 16 Lipopeptide based dispersant Fuel Oil Oman light crude oil Arabian light crude oil Diesel oil Oil dispalcement (%) 100 80 60 40 20 0 10 (% w/v) 100 (% w/v) 1 (% w/v) BSF foamate 3 (% w/v) 4 (% w/v) BSF powder 10 (% w/v) 10 (% w/v) 10 (% w/v) Slickgone NS Tween20 Oil displacement activities of foamate and powder were comparable to a commercial dispersant (Slickgone NS) and much higher than a synthetic surfactant (Tween 20). 17 Conclusions 1 2 3 4 Lipopeptide biosurfactant could be produced from chitosan-immobilized Bacillus sp. GY19 in stirred tank fermenter. Lipopeptides could be recovered from cell-free culture medium by foam fractionation process. Lipopeptides have good surface activity, low toxicity, and stable under various conditions. Both foamate and powder containing lipopeptides could be used directly as dispersants for oil spill remediation -PTT Group Use only- 18 Acknowledgements Sarintip Vaewhongs Chatree Tankunakorn Komkrit Suttiponparnit Project advisor Project leader Researcher Witchaya Rongsayamanont Nichakorn Khondee Onruthai Pinyakong Ekawan Luepromchai 19