CDM Application on Power Sector Projects (Engr Arshad Chughtai

advertisement

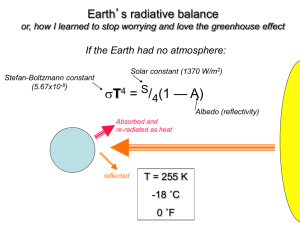

CDM APPLICATION ON POWER SECTOR PROJECTS ENGR ARSHAD CHUGHTAI CONSULTANT PLANNING (POWER) NTDC Background • Only a portion of the solar energy hits the Earth • The remainder either returns to space • Or is absorbed by the atmosphere • Upon contact with the incident radiation, the Earth heats up and emits this energy in the form of infrared radiant heat • Directed towards space, a portion of this radiation is intercepted and absorbed by the greenhouse gases. The Greenhouse Effect The Greenhouse Effect is a natural phenomenon that allows us to survive on Earth. Without the greenhouse effect, average global temperatures would be – 18oC rather than the current 15oC. The green house effect is the process by which absorption and emission of infrared radiation by the gasses in the atmosphere warm planets lower atmosphere and surface. It was proposed by Joseph Fourier in 1824 and investigated quantitatively by Svante Arrhenius in 1896. Global Warming is an increase in the average global temperatures caused by an increase in concentration of gases that trap the sun’s energy. The global mean surface temperature increased over the 20th century by about 0.6oC. Resulting Impact Snow cover and ice extent have decreased; Global average sea level has risen and ocean heat content has increased. Higher maximum temperatures and more hot days over nearly all land areas; Higher minimum temperatures and fewer cold days and frost days over nearly all land areas; More intense precipitation over numerous regions; Increased summer continental drying and associated risk of drought over most middle latitude continental land areas; Increase in number of infectious diseases due to higher nocturnal temperatures (malaria already reaching higher altitudes where it was previously unknown). Fall in agricultural production of staple crops such as wheat and corn due to higher temperatures. Sources Green House Gasses Carbon Dioxide (CO2) – Stems from combustion of fossil fuels, linked to transport and the production of heat or electricity, certain industrial process; deforestation. Methane (CH4) – Stems from agriculture, oil and gas activities, and waste management activities. Nitrous Oxide (N2O) – Stems from agriculture, the chemical industry and combustion activities. Sulfur Hexafluoride (SF6), Per fluorocarbon (PFC), and Hydro fluorocarbon (HFC) stem from specific industrial processes (manufacture of aluminum, or magnesium, the semi-conductor industry), and from aerosols, air conditioning and insulating foam. The Kyoto Protocol 1997 International treaty signed in Kyoto Japan: • Sets an emission reduction target for 40 industrialized nations: Overall, nations must reduce GHG emissions by 5% below 1990 levels. Because each GHG is different and has different global warming impacts, emission reductions described in tCO2eq. • 1 tonne of CO2 = 1 tCO2-eq=1 carbon credit • 1 tonne of CH4 = 21 tCO2-eq=21 carbon credits • 1 tonne of N2O=310 tCO2-eq=310 carbon credits • 1 tonne of PFC = 9,200 tCO2-eq= 9,200 carbon credits. • 1 tonne of SF6 = 23,900 tCO2-eq=23,900 carbon credits IMPACT OF EMISSIONS FROM ELECTRICITY GENERATED On average, each Mega Watt hour (Mwh) of electricity generated in the U.S results in the emission of 1,341 pounds of carbon dioxide (CO2), 7.5 pounds of sulphur dioxide (SO2) and 3.55 pounds nitrogen oxide (NOx). Thus the 10 million Mwh of electricity generated annually by US. Wind farms represents about 6.7 million tons in avoided CO2 emissions, 37,500 tons of SO2 and 17,750 tons of NOx. This avoided CO2 equals over 1.8 million tons of carbon, enough to fill 180 trains, each 100 cars long, with each car holding 100 tons of carbon every year. EMISSIONS FROM FUEL ENERGY CHAIN Energy/Technology Plant Emissions Other Chain Steps Total LIGNITE 1990S Technology (high) 359 7 366 1990s Technology (low) 247 14 261 2005-2020 Technology 217 11 228 1990s Technology (high) 278 79 357 1990s Technology (low) 216 48 264 2005-2020 Technology 181 25 206 1990s Technology (high) 215 31 246 1990s Technology (low) 195 24 219 2005-2020 Technology 121 28 149 1990s Technology (high) 157 31 188 1990s Technology (low) 99 21 120 2005-2020 Technology 90 16 105 COAL OIL NATURAL GAS Kyoto Protocol and Carbon Credits • Provides financial incentives for investors in developing countries to invest in most efficient and environmentally friendly technologies; • Facilitate the most cost-effective reductions of GHGs • It costs comparatively less to reduce one tonne of CO2 in developing Countries than in the developed countries. • It helps developing countries continue on path of industrialization and leapfrog over most pollution-intensive stages; How to Implement Carbon Credit Projects Invest in new, cleaner, more efficient technologies, such as the following: • Construct and operate a wind farm or hydropower plant – will displace electricity produced from fossil fuels; • Application of biomass fuels instead of fossil fuels, such as rice husk, biogases, or MSW instead of coal; • Capture waste heat to produce additional electricity, thereby reducing overall fuel consumption; • Replace older, less efficient equipment with newest models available in the market. It is to ensure that investment in technology goes above and beyond the environmental performance of the business-as-usual scenario in the country. Carbon Credit Project Process The project must first be approved by host country and validated by a third-party auditor. After validation, the project is submitted to the United Nations for approval by the Clean Development Mechanism Executive Board. For validation and approval, the project must first meet certain eligibility criteria, as well as use an approved methodology for determining emission reductions. Subsequent approval, the project is closely monitored to ensure that emission reductions are achieved. Monitoring data will be evaluated by a third-party auditor. Carbon Credits are only issued once monitoring data are verified by the auditor and the issuance is approved by the United Nations. Initial Costs Protect Identification Project Formulation National Approval Carbon credit processsteps Submission of PDD & Country Approval to Validator Validation Submission of PDD & Validation Report to CDMEB Recurring Costs Monitoring Registration Monitoring Submission of Monitoring Report to DOE-B Verification/Certification Submission of Monitoring Report to DOE-B Verification Certification Submission of request for CERs Submission of request for CERs Issuance of CERs Issuance of CERs Criteria Country is a signatory to the international treaty to climate change and has ratified Kyoto Protocol and set up DNA for approve projects. Project must reduce/displace one of the six greenhouse gases. Project must not have been commissioned yet. Emission reductions should be additional to emission reductions that would occur under normal business-as-usual scenario. Required funding must not divert official development assistance. Project must contribute to the country’s sustainable development. Project must use technology that is readily available in a market. Criteria Carbon Credit revenue essentially to be a part of feasibility study. If a project has already commissioned – and it has not got carbon credits– that means it did not need carbon credits in the first place. Carbon credits are intended to provide a financial incentive to invest. But if one has already invested without considering carbon credits, apparently such incentive was not required. Additionality The Clean Development Mechanism provide financial incentives to invest in new / more efficient / cleaner technologies. It is essential to prove Additionality. Carbon credit revenue need to play a role in decision-making while considering investing in a project! What are the barriers to your investment? Barriers on Investment: Cost, financial penalties, lack of available service providers, lack of skilled technicians, etc. POWER SECTOR CARBON CREDIT PROJECTS 1. Replacement of Incandescent Bulbs/ Tube-lights with Energy Savers on Domestic and Commercial Consumers 2. Provision of Capacitors on Industrial and Agricultural Loads 3. Conversion of Street Lights to Solar Power System 4. RMS/AMR Smart Metering 5. Revamping of Thermal Plants 6. SF-6 Gas Leakage Reduction 7. Replacement of Energy Inefficient Irrigation Tube wells pump / motors with energy efficient standard agricultural pumps / motors 8. Installation of Energy Efficient Distribution Transformers CDM PROJECT COMPONENTS/ STEPS Minimum Project Requirements 1. Type of Project Greenhouse gases targeted covered under the Kyoto Protocol (CO2, CH4, N2O, HFCs, PFCs and SF6) 2. CER Volume Minimum threshold of 50,000 tCO2e/year 3. Additionality Why the project should not happen without CDM revenue? 4. Project Participants and institutional Arrangement Demonstration of sound legal arrangement and technically experienced 5. Viable Business and Operation Model •Potential for scale-up •Involvement of intermediaries who can invest, bundle, and implement project-related CDM services locally. 6. Expected Schedule 7. Financing •The baseline component of the project should be financed by project developer; •Payment on delivery of Emission Reductions. 8. Technical Summary of Project Project should be replicable and/or facilitate technology transfer for the country; 9. Expected Environmental Benefits The project can be demonstrate sound environmental benefits 10. Safeguard Policies of the World Bank Group The project must be consistent with the World Bank safeguard policies and the host country’s overall sustainable development framework 11. Contribution to Sustainable Development As defined by the host country. Project Cycle SR STEP/COMPONENTS NO DURATION 1. 3 months 2. Project Identification and Initiation Project Preparation 3. Appraisal 3 months 4. Negotiation and Registration 2 months 5. Construction, Implementation and Supervision Up to 2012 6. Verification, Certification and Supervision Up to 21 years 7. Project Closed Up to 21 years 2 months Project Idea Note (PIN) PIN – Project sponsors / proponents submit potential projects for consideration to the CFU in the form of a Project Idea Note (PIN). Early Notification and Letter of Endorsement (LoE) LOE – If the PIN was submitted by a third-party project sponsor, and the CFU decides to develop it further, the Host Country (e.g the UNFCCC National Focal Point) will be notified of the project. Carbon Finance Document (CFD) CFD – CFU experts will investigate further and evaluate particular aspects of the project in discussions with the project proponent and prepare a CFD with the risk assessment. Letter of Intent LoI LOI – The CFU formally signals its intention to purchase emission reductions generated by a specific project under terms agreed in return for the exclusive right to contract for the purchase of emission reductions. World Bank Due Diligence World Bank Due Diligence – All projects must comply with World Bank Group Operational Policies and Procedures, including those on environmental assessment. An Integrated Safeguard Policies review and Environmental Assessment (EA) is performed as a standard part of the appraisal of World Bank Group Projects. Baseline Study (BLS) and Monitoring Plan (MP) BLS and MP – Once the CFU has decided to include the project in the Portfolio, it will commission a Baseline Study and Monitoring Plan, if the project is not applying an approved methodology. Project Design Document (PDD) • PDD – A project – specific document required under the CDM which will enable the Operational Entity (OE) to determine whether the project: – (i) has been approved by the parties involved in a project, – (ii) would result in reductions of greenhouse gas emissions that are additional, – (iii) has an appropriate Baseline and Monitoring Plan. The PDD is prepared by the CFU and project sponsor. Validation Validation – After the BLS, MP and PDD have been satisfactory developed, the CFU engages an Independent Validator (Designated Operational Entity, DOE) to validate them. This means that the Validator agrees that the ERs are additional to the baseline, the MP is sufficient, and that the ERs have a high chance of being certified under the Kyoto Protocol. Registration Registration – The designated Operational Entity (DOE) contracted to undertake validation, upon the request of the CFU, submits the validation report and validation opinion to the Executive Board, along with a request for registration, together with the PDD, Baseline Study, MP, stakeholder consultation documentation and LoA, plus any other appropriate supporting documentation. Negotiation of Emission Reduction Purchase Agreement (ERPA) Negotiation of ERPA – After the consultations, the CFU legal team prepares a ‘term sheet’ and/or a draft ERPA for further discussion the project sponsor. Initial Verification / project commissioning Initial Verification / Project Commissioning – After the project’s construction and before its commissioning to produce ERs, the CFU contracts an Independent Third Party (a Verifier) for the project (different from the Validator). The Verifier will establish contact with the project and undertake an Initial Verification, which should confirm that the project is ready to generate verifiable and certifiable ERs. This will trigger the CFU acceptance of ERs from the project. Monitoring • Monitoring – As part of project implementation, the project operator must implement the MP, which provides a methodology and a tool for measuring and calculating the emission reductions generated by the project. Once the project starts to generate emission reductions, the project entity monitors the project in accordance with the MP. Verification and Certification • Verification and Certification–Verification and certification of the emission reductions will be undertaken periodically in accordance with the MP and other applicable guidelines by a DOE, who is contracted for the project by the CFU. The verifier will submit a verification report to the UNFCCC CDM Executive Board (EB) for a certification, which will confirm that the ERs have been achieved in the verification period in compliance with applicable CDM rules. Transfer of Certified Emission Reductions (CERs) • Transfer of CERs – Once the ERs are certified, the CFU will pay for the amount of ERs as agreed in the ERPA and the ERs are transferred to Participants in accordance with the ERPA and / or Host Country Agreement and applicable UNFCCC or other rules. POWER SECTOR CARBON CREDIT PROJECT • REVAMPING OF THERMAL PLANTS, ENHANCEMENT OF EXISTING THERMAL GENERATION CAPACITY OF GENCO’S • • • • • • • • • • • • • • • • • • • • • Rehabilitation / Efficiency Improvement Plans of GENCO’s Jamshoro Unit 1-4: Capacity to be Regained: 95MW Heat rate to be improved: 4% Additional Energy: 530MKWH / Year, Fuel savings: 11.4 million US $ year Availability to be increased by 4-5%. Muzaffargarh Unit 1-6 Capacity to be Regained: 165MW Heat rate to be improved :12% Additional Energy 930MKWH/year Fuel saving: 17 million US $ / year Availability to be increased by 3-4%. Guddu Unit 1– 4 Capacity to be Regained: 180MW Unit 11,12 & 13 Capacity to be Regained 125MW Unit 5,7 & 8 Capacity to be Regained 55MW Total Optimization of GENCOs 620 MW ENVIRONMENTAL IMPACT (APPROXIMATE) Average g /KWh CO2 = 414 Tons/KWh CO2 = 0.000414 t CO2-eq Tons/ MWh CO2 = 0.414 t CO2-eq 1 ton CO2 Emission Reduction = 1 Carbon Credit CO2 Emission Reduction from Capacity Gain/Enhanced Capacity of Existing Thermal Plants of 675 MW = 620x0.414 t CO2 –eq = 256.68 t CO2 –eq CO2 Emission Reduction Per Annum = 256.68x8760 = 2,248,516.8 t CO2 –eq 2,248,516.8t CO2 – eq = 2,248,516.8 Carbon Credits Carbon Credits Per Annum = 2,248,516.8 POWER SECTOR CARBON CREDIT PROJECT CONVERSION OF THE EXISTING 366MW STREET LIGHTING LOAD TO SOLAR POWER SYSTEM. • • • • • • • • • • • The Solar Lighting Systems consist of Lighting Equipment (lamp) with a rechargeable battery and a photovoltaic module. Photovoltaic (pv) modules consist of solar cells which can convert sunlight directly into electricity. Solar LED street lights present the perfect and cost-effective solution for residential streets, roadways, and other general area lighting applications. Solar street lights can be economically viable and efficient in a number of applications. Due to their low power consumption and very long life-span, solar LED street lights are a good alternative to LPS (Low Pressure Sodium) Unlike LPS lamps that produce a yellow-orange light, Solar street lights using LED technology generate a very powerful and targeted crisp white light of excellent quality, which significantly improves color rendition and night visibility. Project Highlights. PEPCO intends to convert the existing street lightning load to solar power system. PEPCO has jurisdiction over 10 Distribution Companies (DISCO’S) LESCO, FESCO, CEPCO, MEPCO, IESCO, PESCO, TESCO, QESCO, HESCO & SEPCO. Total number of Street Light Connections in Disco’s is 83302. Load of street lights : 366 MW DISCO wise break up of street light connections is as under: • • • • • • • • • • • LESCO: 1837 GEPCO: 458 FESCO: 1375 MEPCO: 1255 IESCO: 1438 PESCO: 838 HESCO&SEPCO: 863 QESCO: 238 TOTAL: 8302 Number of Lighting Points: 639704* Local Bodies involved are also being dovetailed into the project. ENVIRONMENTAL IMPACT (APPROXIMATE) Average g /KWh CO2 = 414 Tons/KWh CO2 = 0.000414 t CO2-eq Tons/ MWh CO2 = 0.414 t CO2-eq 1 ton CO2 Emission Reduction = 1 Carbon Credit CO2 Emission Reduction from Power = 366x0.414 t CO2 –eq = 151.524 t Saving of 366 MW CO2 –eq CO2 Emission Reduction Per Annum = 151.524x3650 t CO2 –eq = on 10 Hours Daily Usage of Streets 553062.6 t Lights CO2 –eq 553062.6t CO2 –eq = 553062.6Carbon Credits Carbon Credits Per Annum = 553062.6 POWER SECTOR CARBON CREDIT PROJECT INSTALLATION OF ENERGY EFFICIENT DISTRIBUTION TRANSFORMERS. • Recently PEPCO has amended specification for Oil immersed Hermetically sealed type distribution Transformers, rated voltage 11/0.415 KV reducing the maximum allowable iron and copper losses on KVA ratings of 5, 10, 15, 25, 50, 100, 200, 400 and 630. • Following table indicate the maximum allowable losses before and after the amendment and the impact of amendment in reduction of allowable losses resulting in increased efficiency. Iron losses (Watt) KVA Before After Copper Losses (Watt) Difference Rating Amendment Amendment Before After Amend Amend ment ment Difference 5 55 44 -11 175 140 -35 10 65 52 -13 320 256 -64 15 85 68 -17 435 348 -87 25 123 98 -25 640 512 -128 50 175 140 -35 1170 936 -234 100 310 248 -62 2020 1616 -400 200 495 396 -99 3410 2728 -682 400 925 740 -185 5600 4480 -1120 630 1350 1080 -270 8150 6520 -1630 • Impact (Power Saving) • Reduction in Iron losses (No load losses) in the Energy Efficient Transformers will effect MW saving of 1.701 MW (On total number of 34080 Transformers Installed and Replaced during 2010-2011) • Reduction in Copper Losses (Load Losses at 60% load factor) in the Energy Efficient Transformer will effect MW saving of 5.2901 MW. • Total Power of Saving = 1.701 + 5.2901 • = 6.9911 MW (Say 7MW) ENVIRONMENTAL IMPACT (APPROXIMATE) Tons/KWh CO2 Tons/ MWh CO2 1 ton CO2 Emission Reduction CO2 Emission Reduction of Power Saving of 7 MW CO2 Emission Reduction Per Annum = 0.000414 t CO2-eq = 0.414 t CO2-eq = 1 Carbon Credit = 7x0.414=2.898 t CO2-eq 25386.48 CO2 -eq Carbon Credits Per Annum 25386.48 Carbon Credits 25386.48 = 2.898x8760 t CO2-eq = 25386.48 t CO2 -eq • • • • • POWER SECTOR CARBON CREDIT PROJECT PROVISION OF LT CAPACITORS ON INDUSTRIAL AND AGRICULTURAL LOADS Among the various energy conservation measures, improvement of low power factor is an area where significant potential for saving exist. The power factor on the Industrial and Agricultural loads can be improved easily by the use of power factor equipment and is normally achieved by a suitable amount of capacitors load to compensate for the presence of inductive load in the system. Poor power factor on the system is also main cause of energy losses. To improve the low power factor on LT side PEPCO has envisaged a plan to install LT capacitors on Agricultural Tube well and small industrial connections as well having load up to 40KW. Total Number of Agriculture Tube well Connections in to DISCO’s :27875 Load on Agricultural Tube well Connections in DISCO’s: 3511 MW. Total Number of Industrial Connections up to 40KW load in to DISCO’s: 239266. • • • • • • • • • • • Load on Industrial Connections in DISCO’s: 2575 MW. Agricultural Connections in DISCO’s LESCO: 51600 GEPCO: 35093 FESCO: 34183 IESCO: 7385 MEPCO: 67374 PESCO: 26651 TESCO: 8377 HESCO&SEPCO: 26555 QESCO: 21055 Impact of Power Factor Improvement • Generally the existing Power Factor is 0.8 and which is required to be improved to 0.95. • The improvement can be achieved by installation of LT Capacitors. By following calculations impact of Power factor improvement on agricultural and industrial loads (up to 40 KW) can be derived concluding that as to how much gainful active power will be achieved or increased. • Agriculture tube well connections No : 278475 • Load : 3511 MW • Gainful Active Power or Active Power Difference: 554.37 MW • Reactive Power Difference or MVAR required to improve Power Factor from 0.8 to 0.95 • = 1480.16 MVAR • Small Industrial Connections NO: 239866, Load: 2575 KW • Gainful Active Power or Active Power Difference: 406.58 • Reactive Power Difference or MVAR Required to Improve the Power Factor from 0.8 to 0.95 lagging = 1085057 MVAR • Total Gainful Active Power/Capacity Increase by Installation of Capacitors = 554.37+406.58 MW = 960.95 MW • Annual Energy Savings by Gainful Active Power/Capacity Increase • = 960.95x8760 MWH • = 8417922000KWH ENVIRONMENTAL IMPACT (APPROXIMATE) Average g /KWh CO2 = 414 Tons/KWh CO2 = 0.000414 t CO2-eq Tons/ MWh CO2 = 0.414 t CO2-eq 1 ton CO2 Emission Reduction = 1 Carbon Credit CO2 Emission Reduction for Gainful Active/Capacity Increase of 960.95 MW CO2 Emission Reduction Per Annum = 960.95x0.414 t CO2 –eq =397.833 t CO2 - eq 3,485,019t CO2 –eq = 3,485,019Carbon Credits Carbon Credits Per Annum = 3,485,019 = 397.8333x8760 t CO2 –eq = 3,485,019.708 t CO2 –eq POWER SECTOR CARBON CREDIT PROJECT SF6 GAS LEAKAGE REDUCTION • SF6 is a nonflammable, colorless, nontoxic, chemically very stable gas which is five times as heavy as air. At atmospheric pressure, its dielectric strength is 2.5 times higher than that of air. • SF6 circuit breakers are installed in NTDC and DISCO’s (LESCO, FESCO, GEPCO, MEPCO, IESCO, PESCO, TESCO, HESCO, SEPCO & QESCO) Transmission Network. • At present there are 12 NOs of 500 KV, 26 NOs of 220 KV, 508 NOs of 132 KV and 173 NOs of 66 KV & 33 KV Grid Stations catering Power to the System. • PEPCO has introduced new technology and old oil and Air CB’s are being replaced with SF6-Gas Type. However during operations leakage is being experienced at different stations, this leakage needs to be reduced / minimized. SF6 GAS CONSUMPTION ON RECYCLING & REFILLING AGAINST LEKEAGES AND DURING MAINTENANCE & SERVICE OF INSTALLED CIRCUIT BREAKERS IN ONE YEAR UTILITY RATED VOLTAGE NO OF CIRCUIT BREAKERS INSTALLED QTY OF SF6 GAS IN INSTALLED CIRCUIT BREAKERS (Kg) QTY OF SF6 GAS CONSUMED for replacement, reduction of leaks, & repair/maintenance (Kg) I II III IV V NTDC 500kv 137 15953.76 659.5 220kv 394 13204 1292.1 132kv 437 9713.4 636.6 132kv 345 3681.05 1195 66kv 06 36.00 5 132kv 183 1671.8 386.5 & 66kv 7 132kv 193 2742 343 66kv 08 132kv 180 2790 100 132kv 123 2229 303.3 66kv 12 175 27 HESCO 132kv 180 1260 472 & SEPCO 66kv 31 156 169 PESCO 132kv 205 2563.7 2180.8 132kv 11 186 120 66kv 4 500,220,132 & 66Kv 2456 56361.71 7889.8 LESCO GEPCO FESCO IESCO 66kv MEPCO 66kv TESCO TOTAL SF6 GAS PURCHASE IN AN AVERAGE YEAR (KG) UTILITY Qty of SF6 Gas Purchased (Kg) NTDC LESCO GEPCO FESCO MEPCO HESCO & SEPCO PESCO QESCO 3700 1100 320 650 1200 300 300 180 Total 7750 ENVIRONMENTAL IMPACT (APPROXIMATE) Average g /KWh CO2 = 414 Tons/KWh CO2 = 0.000414 t CO2-eq Tons/ MWh CO2 = 0.414 t CO2-eq 1 ton CO2 Emission Reduction = 1 Carbon Credit 1 ton SF6 Emission Reduction = 23900 Carbon Credit Leakage of SF6 Gas Reduction (Kg) = 7889 Kg Leakage of SF6 Gas Reduction (Tons) SF6 Gas Emission Reduction = 7.889 ton SF6 Emission Reduction Per Annum Carbon Credits Per Annum = 7.889x23900 = 7.889 ton = 188547.1 • • • • • POWER SECTOR CARBON CREDIT PROJECT REPLACEMENT OF ENERGY INEFFICIENT IRRIGATION TUBEWELL PUMPS/MOTORS WITH ENERGY EFFICIENT STANDARD PUMP/MOTORS One million tube wells in the country heavy on power and fuel are known to be extremely inefficient in operations. Total number of agriculture tube wells installed in DISCO’s is 278475 with the load of 3511 MW, (Out of which the number of tube wells are 219584 with a sanctioned Load of 2908, 858 MW) while the remaining are diesel driven pumps. According to survey carried out by ENERCON and other consumer groups the efficiency of the present pumps is only 30% of the standard equipment. The pump sets are old centrifugal, turbine or submersible. Tube well Efficiency Improvement Program (TWEIP) USAID has initiated a Tube well Efficiency Improvement Program. A pilot program focusing within the jurisdiction of Multan Electric Power Company (MEPCO) to replace, 1000 old and inefficient agricultural tube well pumps sets (Pumps and Motors) with energy efficient tube well pump set has been commenced. USAID is Subsidizing 50% of the equipment cost for the farmers. The country wide program has a target a total number of 1000 tube wells in seven DISCO’s (MEPCO, FESCO, LESCO, GEPCO, IESCO, HESCO & PESCO). • Energy Savings • Post replacement audits on 324 sites concluded that average pump set Energy Efficiency (%) has been enhanced from previous 37.45% to 54.85% and the average demand per pump set (Kw) reduced to 12.57 Kw from 19.57 Kw previously meaning there by 5.38 Kw savings per pump set replacement. • On the basis of above Taking into account the total number of inservice/active Tube wells in the DISCO’s the Energy Savings to be generated from the replacement of old and inefficient agricultural tube well pump sets with energy efficient tube well pumps sets will be = 219584x5.38Kw = 1181 MW • Estimated Power Saving: 1181 MW • Average Operational Hours: 10 hours per day. ENVIRONMENTAL IMPACT (APPROXIMATE) Average g /KWh CO2 Tons/KWh CO2 = 414 = 0.000414 t CO2-eq Tons/ MWh CO2 = 0.414 t CO2-eq 1 ton CO2 Emission Reduction = 1 Carbon Credit CO2 Emission Reduction from Power = 1181x0.414 t CO2 –eq = 488.934 to CO2 – Saving of 1181 MW on Replacement eq of in Service Inefficient Tube Well Motors/Pumps by Installation of efficient Pumps and Motors CO2 Emission Reduction Per Annum on 10 Hours Daily Operation Basis = 488.934x3650 = 1,784,609 t CO2 –eq 1,784,609 t CO2 –eq = 1,784,609Carbon Credits Carbon Credits Per Annum = 1,784,609 POWER SECTOR CARBON CREDIT PROJECT PROVISION OF RMS/AMR, SMART METERING – AS A DSM ACTIVITY PEPCO Manages 10 DISCOS, (LESCO,FESCO, GEPCO, MEPCO, IESCO, PESCO,TESCO, HESCO, SEPCO & QESCO) More than 20.05 million customers are served through primarily Electro Magnetic Meters and lately Digital meters have also been inducted. The Digital Meters have a proven record of reducing the line losses by eliminating theft of electricity. PEPCO intends to arrange for a remote system capable of measuring electricity consumption/ Customer usage besides generating all other information and data needed to run its specified Management information system (MIS) without the glitches inherent to the existing normal system. A major requirement of the system is to control the present level of administrative losses i.e. pilferage, theft and stealing of energy constricted installation of energy meters by-passing of the same and other such internal and external features. Introduction of Advanced Metering Infrastructure (AMI) fully incorporating RMS/AMR systems is expected to relieve the Distribution system of the present extravagant use / wastage. Consequently thereby it will significantly relieve the generation system. AMI and Its Benefits • • • • AMI, in its essence, serves to move data and control signals between a consumer’s energy consumption and the DISCO that provides the electricity. The most basic level of AMI is called automated meter Reading (AMR). More sophisticated use of AMI involve two – way communication between the Distribution company and the smart Meter so data is transmitted in real time to the distribution company and tariffs and other control signals can be sent to the meter. Benefits: Customer service is improved through Remote Meter Reading and efficient data management. Power outages can be detected, identified and corrected more quickly for customers whose meters are connected to and work. Direct load Control: AMI allows for the energy flow to be set at a peak threshold on a per meter basis at specific times during the day. This allows the distribution company to do load shedding without having to completely switch off entire feeders as is currently the case. Peak usage is minimized. Consumers can benefit from lower electricity bill by using smart card controlled energy meters. Improve metering accuracy despite nonlinear loads. Number of Consumers in DISCO’s • • • • • • • • • • • • • • LESCO 3270611 GEPCO 2618344 FESCO 2846236 IESCO 2109791 MEPCO 4177546 PESCO 2566686 TESCO 438670 HESCO & SEPCO 1531587 QESCO 499184 Entire Customer Base PEPCO 20,058,815 Total Sanctioned Load 47,716,148 KW Number of Single Phase Connections: 19261606 Number of Three Phase Connections: 797210 Estimated Power Saving: 500 MW ENVIRONMENTAL IMPACT (APPROXIMATE) Average g /KWh CO2 = 414 Tons/KWh CO2 = 0.000414 t CO2-eq Tons/ MWh CO2 = 0.414 t CO2-eq 1 ton CO2 Emission Reduction = 1 Carbon Credit CO2 Emission Reduction from Power Saving of 500 MW on PROVISION OF RMS/AMR, SMART METERING = 500x0.414 t CO2 –eq = 207 t CO2 –eq CO2 Emission Reduction Per Annum = 207x8760 = 1,813,320 t CO2 –eq 1,813,320t CO2 –eq = 1,813,320 Carbon Credits Carbon Credits Per Annum = 1,813,320 SUMMARY POWER SAVINGS AND CARBON EMISSIONS REDUCTION (TENTATIVE) Sr. No. Name of Project Power Saving (MW) Carbon Emissions Reduction per Annum (t CO2-eq) 1. Installation of Energy Efficient Distribution Transformers 7 25386.5 2. Provision of LT Capacitors on Industrial and Agricultural Loads 960.95 3485019 3. SF6 Gas Leakage Reduction - (7.889 ton SF6) 188547.1 4. Conversion of Existing 366 MW Street Lighting Load to Solar Power System 366 553062.6 5. Revamping of Thermal Plants- Enhancement of Existing Thermal Generation Capacity of GENCO’s 620 2,248,516.8 6. Replacement of Energy Inefficient Irrigation Tube well Pumps/Motors with Energy Efficient Standard Pumps/Motors 1181 1784609 7. PROVISION OF RMS/AMR, SMART METERING – AS A DSM ACTIVITY 500 MW 1,813,320 3634.95 10,297,926 Total THANK YOU LET US ALL CONTRIBUTE TO THE ENVIRONMENT AND CLIMATE CHANGE.