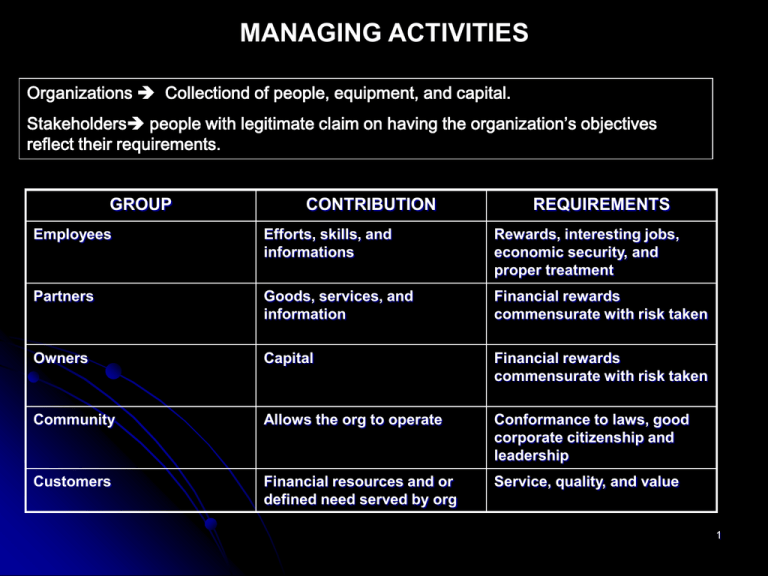

MANAGING ACTIVITIES.

advertisement

MANAGING ACTIVITIES Organizations Collectiond of people, equipment, and capital. Stakeholders people with legitimate claim on having the organization’s objectives reflect their requirements. GROUP CONTRIBUTION REQUIREMENTS Employees Efforts, skills, and informations Rewards, interesting jobs, economic security, and proper treatment Partners Goods, services, and information Financial rewards commensurate with risk taken Owners Capital Financial rewards commensurate with risk taken Community Allows the org to operate Conformance to laws, good corporate citizenship and leadership Customers Financial resources and or defined need served by org Service, quality, and value 1 Organization As a Sequence of Activities Activity A unit of work (task) with a specific goal Exp. Fast food restourant Activities Acquiring Raw materials Hiring & Training Employees Produce Foods Serving customers Responding to customer complaints Value Chain A sequence of activities whose objective is to to provide a product to customer or provide intermediate good in a larger value chain Classes of activities in the value chain: 1. Activities relating to getting ready to make the product (input activities) R & D, hiring & training employees, buying raw materials, components, and equipments 2. Activities relating to making the product (processing activities) operating machines, moving WIP, storing WIP, inspecting partly completed work 3. Activities relating to dealing with the customers (output activities) selling activities, billing, service, and distribution activities 4. Other activities that support the first three activities (administratice activities) administrative functions including personnel, accounting, and general administrative offices Evaluation of all activities in the value chain should be from customer’s prespectivefocuses on meeting the needs of its customers 2 Fast Food Restaurant. Customer Corporation Consistent quality of product, deliver quickly, and costs less than competitors Improve the performance of each activities by managing the activities in a way that is both effective and efficient Effective a process that meets its objectives Efficient a process that uses the fewest possible resources to meet its objective Steps in improving effectiveness and efficiency of organization’s activities; 1. Charting: Identifying each activity in the value chain (produce and deliver product to customer) and visually depicting it 2. Performance measurement: measuring the performance of an activity 3. Analyze: study the performance measures and the way activities undertaken. Identify opportunities or problems for improving the performance of each activities 4. Activity improvement: implement to improve the customer-relevant performance of activities 3 Performance Measures Critical performance indicators performance measures used to asses an organization’s performance on its critical success factors Critical success factors: 1. Service (value in use) the product’s tangiable and intangiable features promised to the customers. Tangiable features: performance, taste, and functionality. Intangiable features: treatment of people whwn making the purchase decision and time to deliver product to customer 2. Quality the similarity between the promised and the realized level of service (giving customers what was promised). “ You wil expect more form meal in a 5 star restaurant than you do from a meal in a fast food restaurant” 3. Cost organization’s ability to minimize the use of resources given the obejctives that it seeks. Product cost Price of the product 4 CUSTOMER PERFORMANCE Service Customer retention rate, number of customers, amount of purchase per customer, % of customer served during peak period, customer satisfaction surveys Quality Number of customer complaintsnper 1.000 orders filled, critical success factors Cost Ratios: costs to revenues, materials in final product to material purchased, and sales per hour during peak operations An effective system of performance measurement contains critical performance indicators that: 1. Consider each activity and the organization itself from customer’s perspective 2. Evaluate each activity using customer validated measures of performance Reflect an understanding of the difference between the output and outcome. Output: physical measure of activity (number unit produced). Outcome: customer values the result of the activity (amount of client satisfaction). 3. Consider all facets of activity performance that affect customers 4. Provide feedback to organization for improvement 5 Understanding Causes Costs Effective cost control customer rqequirements activities costs Performance improvement improved activity management Development of activity data/information (Amount time for production and delivery, amount of material handled, Storage space for factory floor, rework done) 6 Actitivites Create Costs Activities Undertaken Activity 1 (Value added, inefficient) Resources Used Costs Raw materials Activity 2 (Non value added, efficient) Activity 3 (Nonvalue added, inefficient) Activity 1 (Value added, efficient) Labours COSTS Equipments Value added actitivity; an activity that, if eliminated, would reduce the product’ service to customer in the long run Exp. acquiring raw materials Nonvalue added actitivity; an activity that presents the opportunity for cost reduction without reducing the product’s service potential to the customer Exp. Supervisor inspects each product. Inspection is value added activity if employees have not been trained to inspect their won work. If they were taught, then activity of inspection would be nonvalue added activity 7 Activity must be efficient and effective Activity should meet other staeholders’ criteria Exp. To lower cost, company spends as little as possible on employees safety, then this create dangerous working environment Airways company eliminate or reduce activities that demanded by rules to keep costs low in order to set low price Activity /value analysis an approach to operation control that involves the application of steps of continuous improvement to an activity Identify process objectives (what customer wants, expects from the process) Charting the existing process ((Activities used to complete the product) Classify all activities (value added and non value added Continuous improve all activities and plan to eliminate nonvalue added activities 8 TIME REQUIREMENTS FOR ACTIVITIES AND CYCLE TIME Reason for organization is inteseted in the amount of time to do a sequence of activities: 1. Number of costs of non production personnel, equipments, and supplies vary proportionally with the time it takes to make a product and these costs can be reduced by eliminating the causes of long cycle time 2. Customers value a prompt response (short process time) o their request for the product Cycle Time total time needed to complete an activity or process Classification of activities: 1. Processing 2. Moving 3. Storing 4. Inspecting 9 Efficinecy of value added activities improves Non value added activities reduces Number of people, equipment, materials, and supplies used to make product decrease Process cycle time reduce Costs will fall 10 Measure for assessing process efficiency Manufacturing cycle efficiency Manufacturing Cycle Efficiency Manufacturing cycle efficiency = Processing Time Processing Time + Moving Time + Storing Time + Inspection Time Exp. Furniture company produces cabinets Cycle Time Activity Time (hours) Processing 23 Moving 12 Storing 475 Inspecting Total 5 515 Manufacturing cycle efficiency = 23 : 515 = 4,5 % Most organizations have manufacturing cycle efficiency < 10 % 11 Facilities Layout 1. Process layout a means of organizing a production activity so that all similar equipment or function grouped together. Exp in the university, the offices of staff in the same department. 2. Product layout a means of organizing a production activity so that equipment or functions are organized to make a specific product. Exp An automobile assmbly line and some hospitals are specialized 3. Cell manufacturing a means of organizing a production activity so that all equipment needed to make a product is grouped together. The machines are flexible and easily adjusted to make a different products. Process layout Moving activity (customer goes to the bank) Processing activity Storage activity Moving activity (bank takes loan application from customer ) (Loan application are accumulated) (Loan application are passed to loan officer) Processing activity Processing activity (loans are deposited in the customer’s acount) (customers are contacted when decision has been made) Processing activity (Loan application are proved by loan officer) 12 Analysis work in process piled up at each of the processing points (bank teller’s desk, bank loan officer’s desk, and regional supervisor’s desk. Weaknesses of proccess layout: 1. Handling work in batches reduces setting up, moving and handling costs, but increase inventory level 2. Works are unbalanced among activity 3. Area managers that process the application try to avoid the work Just In Time Manufacturing Concept of JIT a means of improve organization performance JIT making a good only when the customer requires it. Manufacturing cycle efficiency equal 1 Elements of JIT: 1. Eliminate nonvalue added activity 2. Continuous improvement 3. Make activities simple 4. Quality commitment 13