The E3 Cost Effectiveness Calculator

advertisement

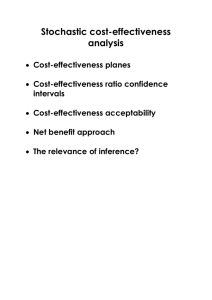

Cost-effectiveness Workshop Three: Energy Efficiency Resources Energy Division September 10th, 2012 1 Workshop Agenda • • • • • • • • • • 2 Introduction and Overview 10:00 – 10:15am Topic 1: Load Shapes 10:15 – 11:15am Break 11:15 – 11:30am Topic 2: Comprehensive Energy Savings 11:30am – 12:30pm Lunch 12:30 – 1:30pm Topic 3: Rebound Effects 1:30 – 2:00pm Topic 4: NTG and Participant Motivation 2:00 – 2:45pm Break 2:45 – 3:00pm Topic 5: Additional Participant Costs and Benefits 3:00 – 3:30pm Other Issues 3:30 – 4:00pm Energy Efficiency Resources Workshop Objectives • To provide parties the opportunity to discuss the cost-effectiveness framework in the context of energy efficiency programs only. • To explore new ideas of how the cost-effectiveness framework could be modified to account for costs and/or benefits specific to energy efficiency programs. This workshop will not re-visit issues common to all demand-side programs discussed during the June workshops. 3 Topic 1: Load Shapes used for Cost-effectiveness Calculations • Background: – The E3 Avoided Cost calculator uses hourly (8760) $/kWh avoided costs for electricity and monthly (12) $/Therm avoided costs for natural gas. – The E3 Cost-effectiveness calculator uses these avoided costs as the TRC and PAC benefit inputs. The benefits are calculated based on the annualized energy saved allocated hourly (electric) and monthly (natural gas). 4 Measure Load Shape • A measure load shape is the measure annual savings impact allocated into each avoided cost hour (electric) or month (gas). – This is not the end use shape but rather the difference between the hourly or monthly value of the measure use shape minus the baseline (code compliant, pre-existing, or non-efficient) use shape. – Shape may be positive (load decrease or savings) or negative (load increase) in each hour or month. – The load shape is “normalized” to 1.0 – the sum of all the values (hourly or monthly) is 1.0 such that multiplying the annual savings by the load shape value provides the savings for each hour or month. 5 Measure Load Shape (cont.) • Measure load shapes can vary by: – Measure type, efficiency level – Building type (due to different use profiles and building configurations) – Location (if there is significant weather or regional sensitivity of savings) • May use “typical” or “average” load shapes if the normalized shape due to the above sources of variation provide similar results. 6 The E3 Cost Effectiveness Calculator • The measure load shapes are inputs to the E3 Cost-Eff. Calculator. • The pre-calculated quarterly benefits are reported for measure groups (lighting, HVAC, process, technologies, etc.) across a range of appropriate variation parameters (building type, location, etc.). • Utilities select values via E3 Cost-Effectiveness Calculator inputs: – Electric: Climate Zone, Target sector, Measure Electric End Use Shape – Natural Gas: Gas Sector, Gas Savings Profile • DEER electric load shapes are supposed to be considered first. Utilities may use other load shapes when DEER load shapes are not available. 7 Load Shape Discussion Questions • Do we need additional load shapes to more accurately calculate the avoided costs of generation energy and capacity? • If so, what type of load shapes should be developed, given that the development of additional load shapes would require significant resources? 8 BREAK • Please return at 11:30am. 9 Topic 2: Measuring Lost Opportunities associated with Comprehensive Energy Savings • TURN’s proposal points to a general energy efficiency program design issue of how cost-effectiveness as conventionally measured does not capture how well EE programs are designed and implemented. • For instance, under current cost-effectiveness, the effects of cream skimming and the resultant creation of lost opportunities are not explicitly considered because there is no metric to determine the economic value of the EE savings that are being “left on the table.” 10 • TURN proposes that this approach should be used in the EE program design and evaluation phases. – What appears to be a very cost-effective program may in fact be cream skimming and creating lost opportunities (ex: CFLs and refrigerator replacement). – What appears to not be a cost-effective program may in fact be cost-effective IF additional EE measures and activities are implemented within the same project (ex: space heating and cooling, water heating, and lighting systems). 11 TURN’s example illustrates what happens if EE programs only achieve part of the otherwise cost-effective EE savings at a hypothetical building site through a simplistic illustration that: • First quantifies the total potential EE savings and calculates lifecycle economic value (i.e., avoided cost) from achieving largely all cost-effective EE measures at a site (assumed residential whole-house type EE program). • Next, quantifies the monetary value of the EE savings achieved via the utility EE program. • Then, subtracts out the economic value of the EE savings that were “left on the table.” • By quantifying the economic benefits (i.e., avoided costs) of the additional savings available but not achieved, this illustrates the additional economic value of a more comprehensive EE building site treatment. 12 Example of Problem • Could achieve $177M benefit for $100M cost: Benefit-cost (B/C) ratio 1.77. • Administrator designs program to get $117M for $60M: B/C ratio 1.95. • But remaining $60M benefits are no longer cost-effective – Either one-time costs must be repeated, or – Lost opportunity that had to be done at the same time as the other work; OR failure to establish follow-up “harvest” of additional EE savings. • Accounting for cream skimming (lost opportunity) = adjusted B/C ratio 1.63. The Calculation Full Program benefits total cost one-time Measure Net benefit benefit-cost As Implemented Remaining 177 117 59 100 25 75 77 1.77 60 25 35 57 1.95 40 TURN Adjustment to Benefit-Cost Calculation net benefit unachievable due to design adjusted benefit-cost 57 (19) 38 1.63 40 19 1.48 LUNCH • Please return at 1:30pm. 15 Topic Three: Rebound Effects from Energy Efficiency Programs • Direct rebound effects occur when a customer purchases an energy efficiency device, but then increases the use of that device, for a net increase in energy use on the grid. • Indirect rebound effects occur when a customer take the money saved through energy efficiency and uses it to purchase new energy consuming devices or pursuits. • Academic papers range the potential impact from rebound effects between 10% of energy savings to greater than 100% of energy savings. 16 Rebound Effects Discussion Questions • Is the rebound effect relevant to California’s energy efficiency programs? To what extent are the various energy efficiency measures likely to be contributing to the rebound effect? • Should rebound effects be captured in energy savings calculations? If so, how? Should effects be captured at measure, program, or portfolio levels? • What reliable data sources are available to inform the impact of rebound effects? 17 Topic 4: Net-to-Gross and Participant Motivation • Parties have commented that the current net-to-gross calculations do not accurately account for participant motivation, especially in building performance programs. • Discussion question: Are the current net-to-gross surveys (as shown on the next slide) sufficiently capturing participant motivation, especially for building performance programs? If not, should we modify the net-to-gross surveys, or is another method required? 18 Net to Gross Survey Results: Reasons for Doing the Project Response Rationale To reduce energy costs To reduce energy use To replace old/outdated equipment To get a rebate from the program As part of a planned remodeling/build-out To gain more control over how the equipment is operated To update to the latest technology To protect the environment To improve equipment performance Needed to increase capacity To comply with codes set by regulatory agencies To improve the product quality Improve equipment reliability Comply with company policies for normal maintenance Had process problems and were seeking a solution Reduce Maintenance downtime/associated expenses To improve plant safety Other Total* 19 Frequency 61 22 17 11 7 7 6 6 5 5 3 3 2 1 1 1 0 11 169 * Multiple responses allowed. from Results of Nonresidential Net-to-Gross CATI Survey Pre-Test, Itron, 2011 Percentage 36% 13% 10% 7% 4% 4% 4% 4% 3% 3% 2% 2% 1% 1% 1% 1% 0% 7% 100% BREAK • Please return at 3:00pm 20 Topic 5: Additional Participant Costs and Benefits • During the June workshops, some parties commented that value of service loss and transaction costs should be considered for energy efficiency programs, as they are for demand response programs. • Value of service loss includes productivity losses (e.g., closure of a business to allow for energy efficiency upgrades) and comfort losses (e.g., delay or poorer quality of light from CFLs). Transaction costs include opportunity costs such as time spent for filling out forms and “hassle” of learning about energy efficiency options. • How should (if at all) value of service loss and/or transaction costs be considered in energy efficiency programs? 21 Additional Participant Costs and Benefits (Cont.) • The cost-effectiveness tests used for the Energy Savings Assistance (low income EE) program include non-energy benefits (NEBS) that accrue to utilities and participants. • During the June workshops, some parties commented that indoor air quality, which is included in ESAP cost-effectiveness tests, may be applicable to all energy efficiency programs. • Should this benefit be calculated for all energy efficiency programs? Are there other non-energy costs and benefits specific to energy efficiency programs that are currently omitted from the costeffectiveness framework? 22 Other Issues 23