Jointing Techniques

advertisement

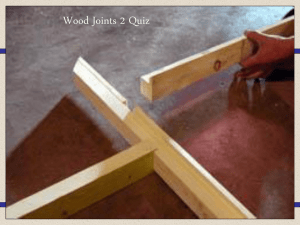

Joining Techniques Wood, Metal and Plastic Design and Manufacture How to join Wood…. • There are 4 main ways to join wood; an adhesive, a joint, a nail or screw or using a knockdown fitting. Common wooden products that you use every day will incorporate some of the joining techniques above. Gluing The majority of the time Polyvinyl acetate (PVA) wood glue will be used to join wood. PVA glue is used in the workshop every day and is the glue you would use to make paper Mache. Nails and screws • There are many types of nails and screws to fit your needs. Some common ones are below. Round head Oval head Countersink or flathead Knock-down fittings • Knock-down fittings are those that can be put together easily, normally using only a screw driver, a drill, a mallet/hammer and other basic tools. They are temporary joints although many are used to permanently join together items such as cabinets and other pieces of furniture that are purchased in a flat pack. Other glues that could be used would be Superglue, epoxy resin, Hot glue, and a number of different resin glues; Phenol formaldehyde resin, Urea-formaldehyde resin. Before these modern glues the glue of choice was animal glue or hide glue. It is manufactured from rendered collagen from the skins (hides) of animals. It is chemically similar to edible gelatine and is non-toxic if ingested. Hide glue is still used today in specialized applications: musical instruments (lutherie), for replica furniture, and for conservational-grade repairs to antique Wood joints Butt Joint The most simple and easiest to make wood joint is the Butt joint. The joint relies solely on the strength of the glue to hold it together. Housing Joints What is a Housing joint? • Housing joints are used when two pieces meet at right angles on their narrow face. A shallow trench is cut across the grain of the vertical member, the shelf or panel is then glued into a simple straightforward housing and all the loads are transferred to the sides of the unit. Pins can further strengthen the joint. What are the advantages of this type of joint? • Simple to make. • Strong. • In its basic form only one component has to be shaped. What are the applications for this type of joint? • Used for fixing shelves to vertical panels in deep cabinets, bookcases, storage units and boxes, or for drawer fronts and carcase/frame construction. Types of Housing Joints: Through housing joint The trench of the though housing goes fully across the piece of wood so the joint can be seen. Stopped housing joint • For decorative effect, the trench of the housing is often stopped short of the front edge of the side panel by some 9 - 12 mm. No part of the joint is visible from the front because the joint is completely concealed. This is particularly important where a high quality finish is required. Mortise and tenon joints What is a Mortise and tenon joint? • The mortise and tenon is one of the most common joints used by woodworkers and is the traditional corner joint for sturdy frames. What are the advantages of this type of joint? • Neat and very strong. • Large surface area for gluing. • It cannot wobble. • Is difficult to pull out. • Most of the joint is hidden in the timber. What are the disadvantages of this type of joint? • Can be fairly difficult to mark out and cut. • Poor resistance to tension, especially if badly fitted. What are the applications for this type of joint? • Used where maximum strength is important in window, door, chair, mirror, bed and table frames and frame-and-panel cabinets or external work like garden or street furniture (seats, tables etc) Through mortise and tenon joint In a through mortise and tenon joint the end grain is visible and the joint needs accurate cutting for good appearance. Haunched mortised and tenon joint In order to include a strong joint at the frame, a haunch is introduced to the joint. The haunch prevents the frame from twisting and makes it firmer, giving it added strength. It also increases the gluing area. Stopped mortise and tenon joint This is the best joint for external work as most of the joint is protected from the weather by tenon shoulders. The joint is strong and concealed and used in furniture construction where a high- quality finish is required. The stopped mortise and tenon joint is a good looking joint because the tenon of this joint does not show on the outside face. The depth of the mortise should be three-quarters of the thickness of the wood being joined. Dovetail What is a Dovetail joint? • Dovetails are the strongest of all joints. The joint is made up of interlocking wedge-shaped elements called pins and tails that resist the forces applied to the joint. This joint looks attractive and, if well made, the decorative quality can be used to enhance projects. In other projects the joint can be hidden completely. Dovetail joints work best when in tension. For example, the most common application of the dovetail joint is in drawer making as the strength of the joints tails and pins resist the pulling forces applied to the drawer. Dovetails are so strong it is rare to see a drawer that has broken as a result of joint failure, even when put under frequent stresses. Finger joint A finger joint or comb joint is a woodworking joint made by cutting a set of complementary rectangular cuts in two pieces of wood, which are then glued. To visualize a finger joint simply interlock the fingers of your hands at a ninety degree angle; hence the name "finger joint." It is stronger than a butt or lap joint, and often contributes to the aesthetics of the piece. Other common wood joints Lap joint T joint Dowel joints How to join Metal…. • There are a number of ways to join Metals. Some common joining techniques are, rivets, adhesives and thermal joining. Women riveting the side of an airplane panel at Ford Motor Company’s Willow Run bomber assembly plant in Ypsilanti, Michigan, August 23, 1944. Riveting Rivets are used to join plates together and they have been used for hundreds of years. Before the widespread use of welding, rivets were used in heavy industries such as ship building. The steel plates used to build ships such as the Titanic and the naval Dreadnaughts of World War One were held together by steel rivets. Rivets have largely being replaced by techniques such as welding and brazing. However, joining plates together with rivets is still a useful technique especially if the plates to be joined are quite small. Cold rivets are still used in school workshops although the modern pop-riveting technique is more popular. Riveting video Adhesives Glues like in wood can also be used with metals. Glues like the epoxy resin can also be used to glue together sections of metal. Thermal joining • Thermal joining means using heat in order to join metal together. Some methods of joining metal together using heat are welding, soldering and brazing. Arc Welding Arc welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point to create a permanent joint. Brazing Brazing is a metal-joining process whereby a filler metal is heated above melting point and distributed between two or more close-fitting parts by capillary action. The filler metal is brought slightly above its melting temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (known as wetting) and is then cooled to join the work pieces together. It is similar to soldering, except the temperatures used to melt the filler metal are higher for brazing. Soldering • Soldering is a process in which two or more metal items are joined together by melting and flowing a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Soldering differs from welding in that soldering does not involve melting the work pieces. Soldering is commonly used in electronics to create circuits. Soldering video