Thermal Cutting

advertisement

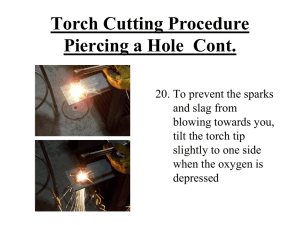

Thermal Cutting 1 Definition A group of processes that use heat to sever metals by melting or by chemical reaction of oxygen with the metal at elevated temperatures 2 A Group of Processes What are the two common thermal cutting processes? 3 Oxyfuel Cutting 4 Definition A group of processes used to sever or remove metals by high temperature exothermic reaction of oxygen with the base metal. (Welding Handbook, 5th ed.) What is an exothermic reaction? 5 Oxyfuel Cutting Principles What is the source of the heat? How hot is the flame? How does the process work? Will compressed air work instead of oxygen? Why is acetylene the preferred fuel gas for thermal cutting? 6 Principles-cont. What type of flame should you use when cutting with oxyacetylene torch? What determines the working pressure for the acetylene and oxygen? 7 Principles-cont. Victor cutting pressure chart Thickness (inch) 1/8 1/4 1/2 3/4 1-1/2 2-1/2 3 Tip Size 000 00 0 1 2 3 4 Drill Size 70 66 59 56 53 50 45 20-25 20-25 20-25 30-35 35-45 40-50 40-50 3-5 3-5 3-5 3-5 3-7 4-10 5-10 Oxygen Pressure Fuel Pressure 8 OxyFuel Cutting Equipment What is the difference between a cutting attachment and a cutting torch? 9 Cutting Attachment A.Oxygen lever B.Oxygen cutting valve C.Oxygen tube D.Attachment head E.Nozzle nut F.Cutting nozzle G.Preheat orifices H.Cutting orifice I. J. K. L. M. N. O. Preheat Oxygen & acetylene Mixing chamber Cutting attachment Preheat oxygen valve Preheat acetylene O-rings Attachment nut 10 OxyFuel Cutting Flame Identify the neutral flame and explain how to tell the difference between the three types of flames? C A B 11 OxyFuel Cutting-cont. Organize the following step for completing an oxyacetylene cut in the correct order. A. Fully depress cutting lever quickly. B. Heat the metal until a spot is cherry red. C. Move torch across the surface of the metal. D. Hold the torch on the edge of the metal with the tips of the inner cones about 1/8 inch from the surface. 12 Four (4) Factors Which Control Quality of Cut 1. 2. 3. 4. Preheat Clearance Speed Pressure What are the indications of excessive preheat? How can you determine if a cut was completed with excessive or insufficient clearance? What are the results of excessive or insufficient speed of travel? How can you tell if the oxygen pressure was set correct? 13 Piercing Steel What hazard can occur when piercing metal with an oxyacetylene torch that isn’t usually present when cutting? Organize the following steps required to pierce a hole in the correct sequence. A. Raise torch 1/2 inch or more above metal. B. Preheat spot until cherry red. C. Once cut breaks through, lower torch and complete the cut. D. Depress cutting lever and simultaneously start torch movement E. Check to insure heat cherry read all the way through 14 Cutting Pipe The first step in cutting pipe is piercing the pipe. After the pipe is pierced two different methods can be used. – Pipe 3 inch diameter and less: cut 90o to the left and right, keeping the torch at the same angle. Rotate the pipe 180o and repeat. – Pipe > 3 inch diameter: cut in quadrants rotating the angle of the torch to stay perpendicular to the surface of the pipe or rotate the pipe. 15 Plasma Arc Cutting 16 Definition In the plasma arc cutting process compressed air is forced through a small orifice at high speed. At the same time an electrical arc is completed from the electrode in the torch to the metal which converts the gas to a plasma. The plasma has sufficient heat and velocity to blow the molten metal from the cut. 17 Plasma Arc Cutting Why was the plasma arc cutting method developed, oxyacetylene cutting was already available? 18 Plasma Arc Cutting--cont. A. Electrode B. Compressed air C. Nozzle D. Plasma E. Standoff F. Base metal 19 Plasma Arc Cutting--cont. Stand off – All plasma arc torches require a distance between the nozzle opening and the metal. – This is called the stand off. Insufficient Stand off – Excessive heat on cutting tip – Accelerated erosion of cutting orifice Excessive Stand off – Reduced heat at cut – Reduced quality of cut Check owners manual on piercing. Most plasma arc torches must start from an edge or have limited piercing capabilities. 20 Questions? 21